1.Product structure: Upper lower tissue (or airlaid ), Cotton core (mix with SAP), ADL,PE flm, Frontal tape, Topsheet hydrophilic nonwoven, Leg cuff hydrophob...

Overall size: 38mx8mx5m (for reference only), Driven system: Servo drive, digital size change, ensure run synchronously at full process.Safety system: Safety gu...

900PCS/MIN | HAINA Intelligent Full Servo Baby Diaper Production Line ✅ High-speed, integrated forming ✅ Unmatched precision stability ...

900 L diapers per minute? Yes, this line can do it!...

Fast, Stable, and Efficient Baby Diaper Machine ...

The Ultimate Diaper Machine: 600 XL/Minute for Growing Factories!...

fully automatic baby diaper machine plays an indispensable role in it. With the continuous advancement of industrial mechanization, mechanical equipment has bee...

This is Pull Up Baby Diaper Machine in Iran, thisPull Up Baby Diaper Machine can produce M/L/XL/XXL sizes for the local market, design speed is 550ppm and stabl...

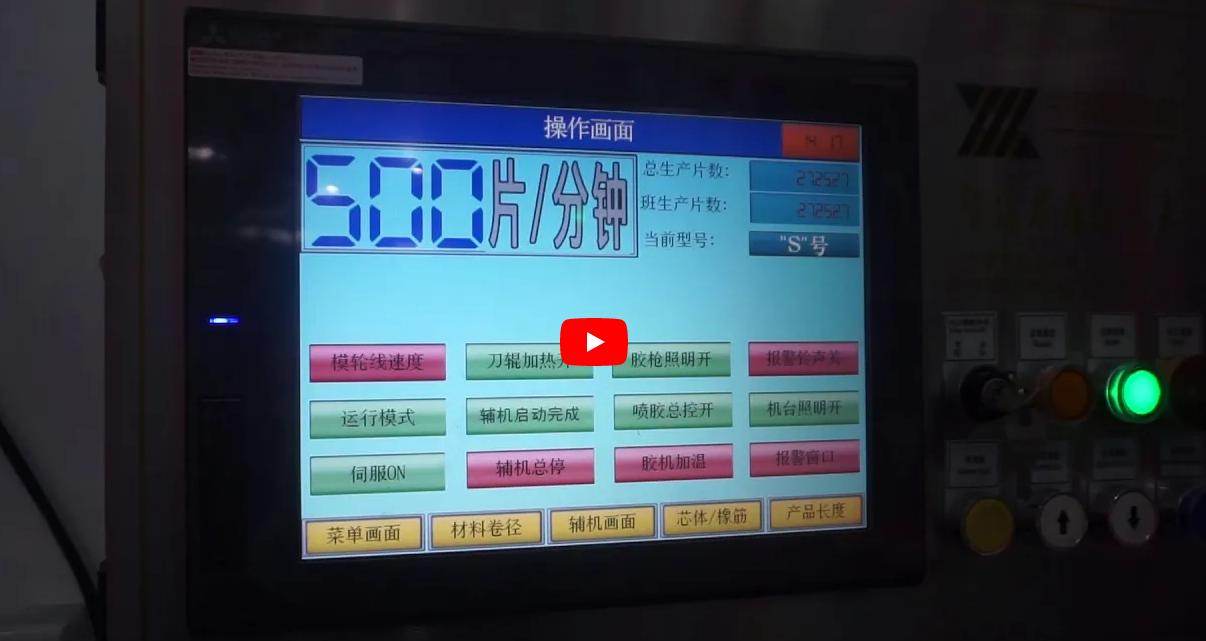

1. T-Shape Ear Type Baby Diaper Machine Program System Servo driven, intelligent HMI touch screen man-machine interface 2. Driven System Servo drive, digital si...

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine i...

Our operational costs have decreased significantly, thanks to the efficiency of the Baby Diaper Machine. It's a cost-effective solution for any diaper manufactu...

We've received positive feedback from parents who love the softness and snug fit of the diapers produced by this Baby Diaper machine. It's a win-win for everyon...

The Baby Diaper machine's flexibility allows us to customize diaper designs according to market trends, giving us a competitive edge. Our customers appreciate t...

The reliability of the Baby Diaper Machine has given us peace of mind. We can fulfill orders on time without worrying about breakdowns or delays....

This Baby Diaper Machine has streamlined our manufacturing process and allowed us to deliver diapers that exceed our customers' expectations in terms of comfort...

With the Baby Diaper Machine, we've been able to expand our product line and meet the growing demand for baby diapers. Our customers are happy, and so are we...

We've seen a significant improvement in production output and product quality since we started using the Baby Diaper Machine. Our customers love the result!...

The Baby Diaper Machine is easy to operate and requires minimal maintenance, saving us time and resources. It's definitely worth the investment....

The Baby Diaper Machine efficient, reliable, and produces high-quality diapers consistently...

The Baby Diaper machine technical support provided by the manufacturer has been excellent, ensuring that our production runs smoothly without any hiccups....

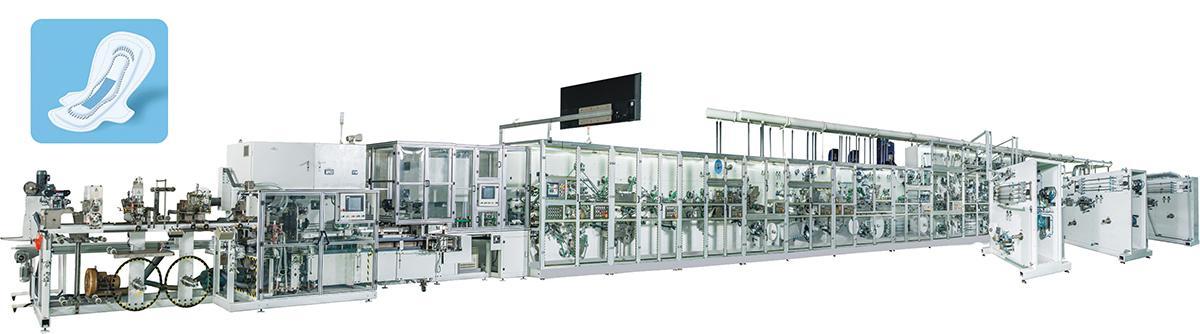

The machine for making sanitary pads is a device designed to manufacture disposable feminine hygiene products. It is equipped with advanced technologies that enable it to produce hygien...

Rejection rate: ≤3%, Product structure: Upper & lower tissue (or airlaid ),Cotton core (mix with SAP), Topsheet hydrophilic nonwoven, ADL nonwoven, Leak cuff hydrophobic nonwoven,3D co...

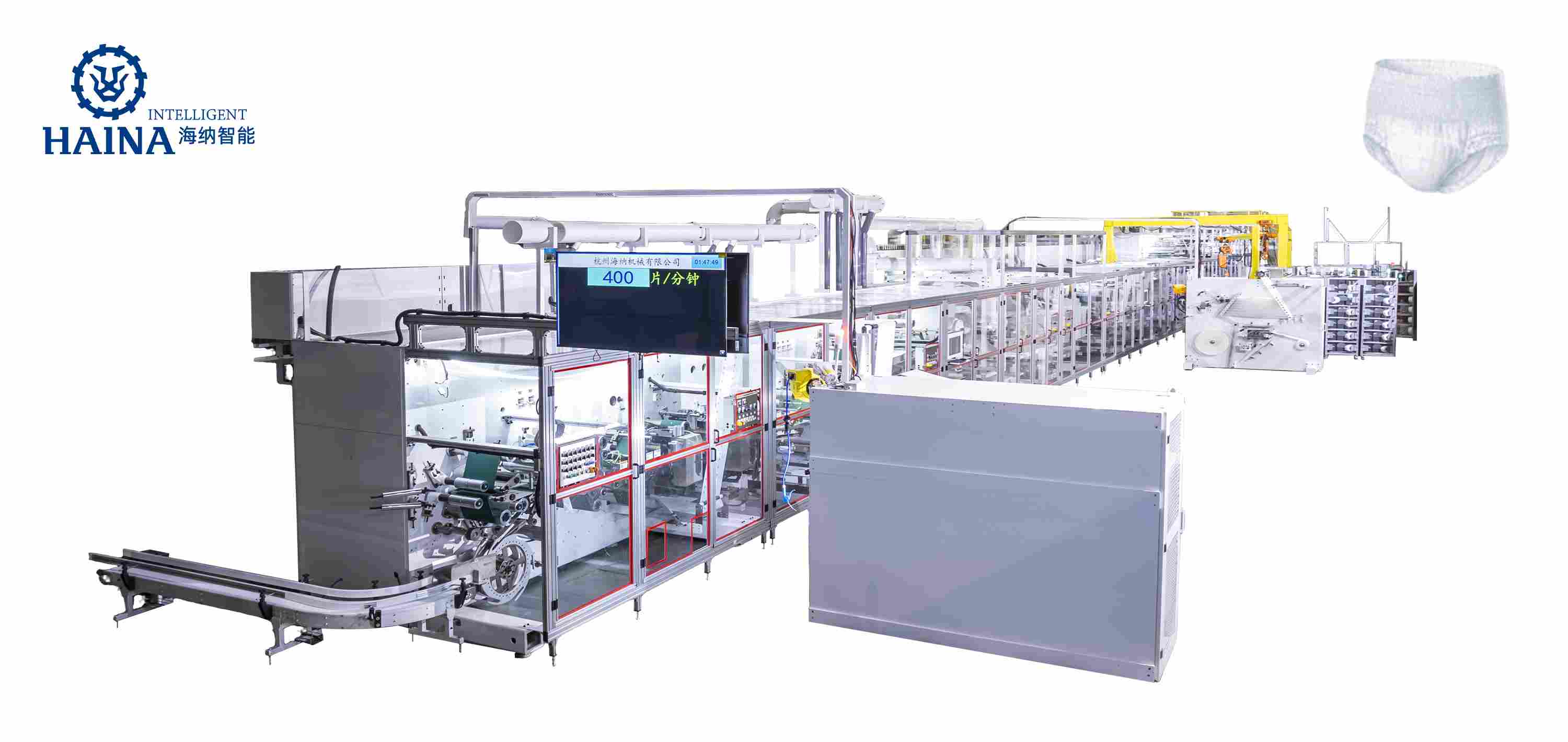

1.Automatic Menstrual Pants Making Machine Product structure: Upper lower tissue(or arlaid), Cotton core (mix with SAP), Topsheet hydrophilic nonwoven, ADL, Leak cuff hydrophobic...

Baby Pants Machine in South Africa, this machine with ultrasonic unit for the waist welding which make the diaper with better performance. The machine speed is 450pcs/min for stable wor...

This is a Haina Full servo pantsdiaper shippedfor south east Asia customers. It can produce four sizes of S / M / L / XL, The stable production speed of M size is 500 pieces / min. ...

Improve baby diaper production line operating techniques...

For manufacturers seeking to transform their output, this high-speed pull-up diaper production line is the definitive solution. Achieving an impressive rate of 800 pieces per minute, i...