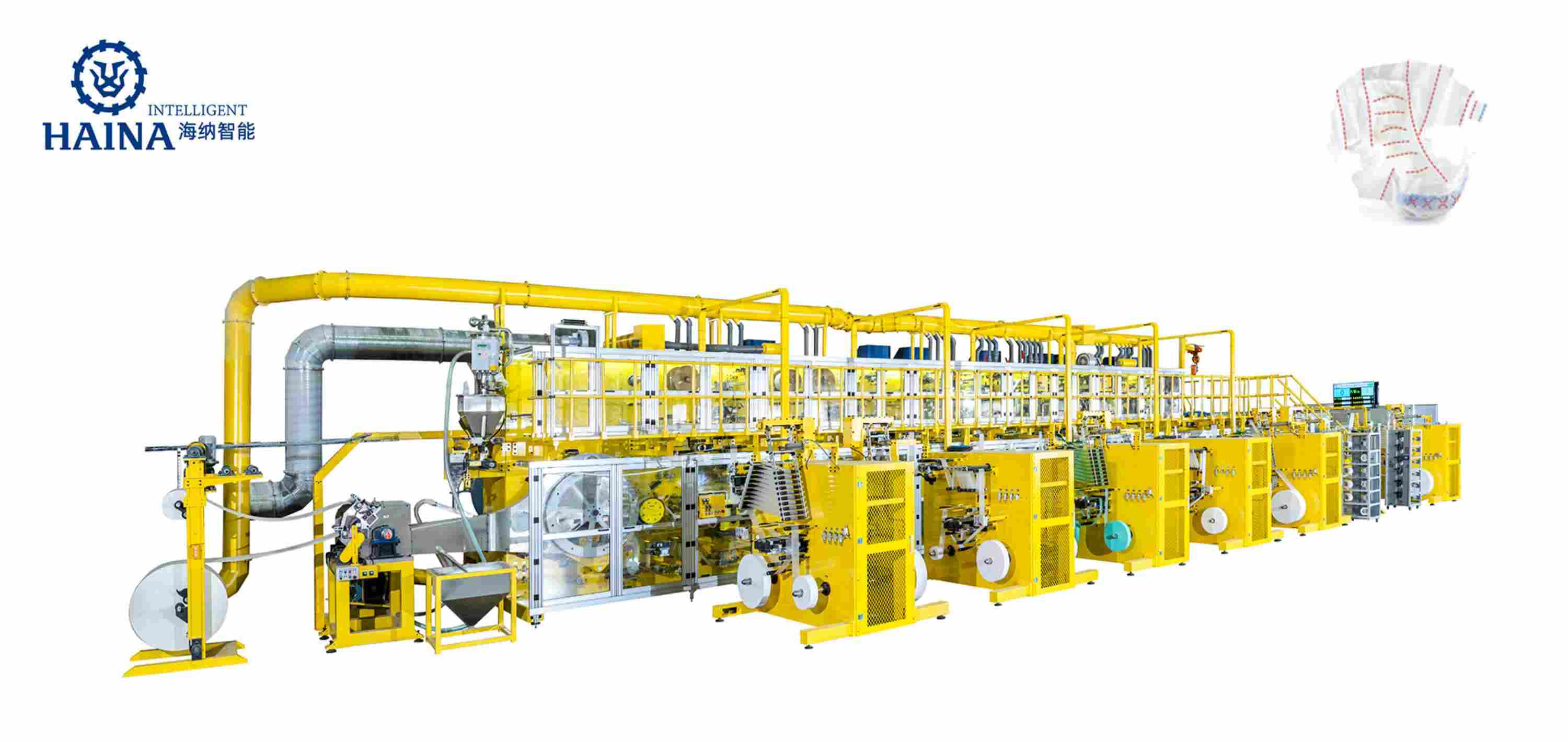

This fully-automatic baby diaper machine saves time and human resources by reducing the need for manual labor and manufacturing high-quality products. It is an ideal choice for diaper manufacturers who want to produce high-quality, cost-effective, and environmentally-friendly baby diapers.

|

Dimensions(L×W×H8) |

30m*6m*3.8m |

|

Design Speed: |

500ppm |

|

Stable Working Speed: |

400-450ppm |

|

Rejection Rate: |

≤4% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

290KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

75 tons |

Strengthen the ability and quality of the operators of Baby Diaper Machine

1. The technical level of maintenance personnel is an important factor affecting the maintenance efficiency of Baby Diaper Machine.

Having a high-quality workforce is the basis for promoting the continuous improvement of equipment maintenance efficiency.

2. The improvement of the technical level of the maintenance personnel of baby diaper Production Line can be carried out in the following ways:

First, take a combination of bringing in and sending out. Second, through internal training and learning, cultivate equipment management, use and maintenance personnel, and use business time to hold equipment use training activities to continuously improve the technical level of personnel. Third, strengthen the improvement of the employee assessment mechanism, increase the assessment of the survival of the fittest, stimulate the enthusiasm of the employees, and also promote the continuous learning of the employees, providing necessary guarantees for the use and maintenance of equipment.

|

No. |

Raw materials |

|

1 |

Hydrophilic NW (Topsheet) |

|

2 |

Hydrophobic NW (Legcuff) |

|

3 |

Elastic for Legcuff |

|

4 |

ADL |

|

5 |

Fluff pulp |

|

6 |

SAP |

|

7 |

Upper tissue/NW |

|

8 |

Lower tissue/NW |

|

9 |

Pe film |

|

10 |

NW for laminating |

|

11 |

Frontal tape |

|

12 |

Elastic NW for big ear |

|

13 |

NW for small ear |

|

14 |

Magic side tape |

|

15 |

Construction glue |

|

16 |

Elastic glue |

|

17 |

Wetness indicator glue |

The baby diaper making machine is a high-performance, fully automated device designed to produce high-quality and hygienic baby diapers. This state-of-the-art machine has several functional advan...

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully automated, w...

Hainaproduction team are loading machines to container. Foreach machine, after finish customer inspection. Production team will start todismantle the ma...

Baby Diaper Machine in Zambia The machine stable speed is 550pcs/min. The customer purchased this machine from Haina machinery in 2022. The company has ...

The Baby Diaper Machine is easy to operate and requires minimal maintenance, saving us time and resources. It's definitely worth the investment.Ethen 2024-05-30

Our operational costs have decreased significantly, thanks to the efficiency of the Baby Diaper Machine. It's a cost-effective solution for any diaper manufacturer.Matthew 2024-05-30

With the Baby Diaper Machine, we've been able to expand our product line and meet the growing demand for baby diapers. Our customers are happy, and so are weLiam 2024-05-30

The Baby Diaper Machine efficient, reliable, and produces high-quality diapers consistentlyjone 2024-05-30