The baby diaper making machine is a high-performance, fully automated device designed to produce high-quality and hygienic baby diapers. This state-of-the-art machine has several functional advantages that make it an ideal option for diaper manufacturers around the world.

In conclusion, the baby diaper making machine offers significant functional advantages that make it a valuable investment for manufacturers seeking a reliable, efficient, and high-quality production solution.

Firstly, the machine is equipped with advanced technology and efficient components that ensure precision, accuracy, and consistency in the production process. This results in a high-quality end product that meets international standards of hygiene and safety.

Additionally, the machine has a high-speed production rate, which allows for a large volume of diapers to be produced in a short amount of time. This increases productivity and efficiency, enabling manufacturers to meet the growing demand for baby diapers in the market.

Furthermore, the machine is easy to operate and maintain, with user-friendly controls and intuitive interfaces that require minimal training. This reduces the risk of downtime due to human error, ensuring a smooth and uninterrupted production process.

Other advantages of the baby diaper making machine include its flexibility, adaptability, and versatility. It can produce a wide range of sizes, styles, and designs of baby diapers to suit the diverse preferences and needs of customers. Moreover, it can also incorporate various features such as absorbency, leakage protection, and comfort-enhancing materials into the diapers.

|

Dimensions(L×W×H8) |

30m*6m*3.8m |

|

Design Speed: |

500ppm |

|

Stable Working Speed: |

400-450ppm |

|

Rejection Rate: |

≤4% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

290KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

75 tons |

Strengthen the ability and quality of the operators of Baby Diaper Machine

1. The technical level of maintenance personnel is an important factor affecting the maintenance efficiency of Baby Diaper Machine.

Having a high-quality workforce is the basis for promoting the continuous improvement of equipment maintenance efficiency.

2. The improvement of the technical level of the maintenance personnel of baby diaper Production Line can be carried out in the following ways:

First, take a combination of bringing in and sending out. Second, through internal training and learning, cultivate equipment management, use and maintenance personnel, and use business time to hold equipment use training activities to continuously improve the technical level of personnel. Third, strengthen the improvement of the employee assessment mechanism, increase the assessment of the survival of the fittest, stimulate the enthusiasm of the employees, and also promote the continuous learning of the employees, providing necessary guarantees for the use and maintenance of equipment.

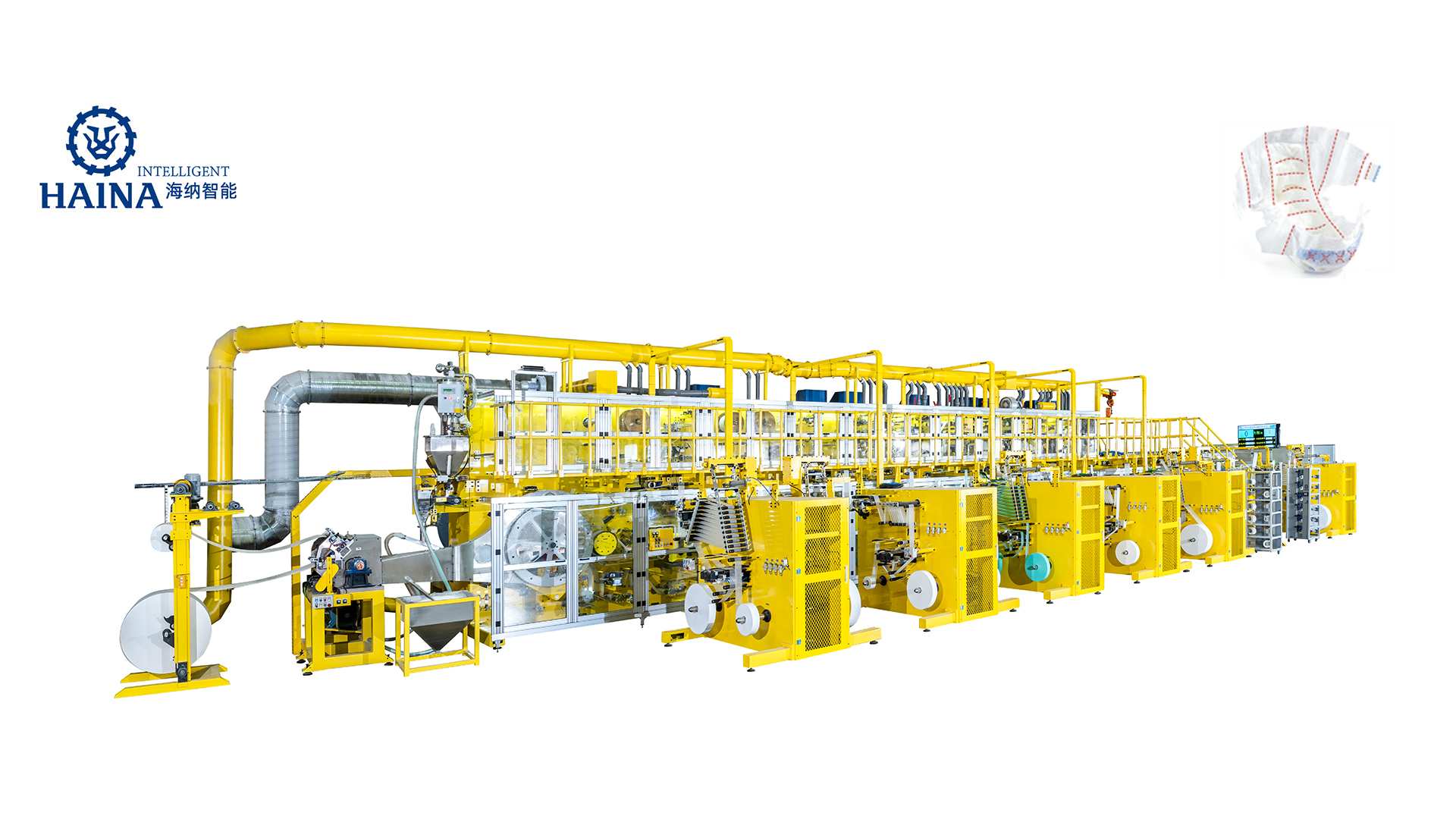

LK850-baby diaper making machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | NW for laminating |

| 11 | Frontal tape |

| 12 | NW for S cut |

| 13 | Hook for S cut |

| 14 | Glue for S cut |

| 15 | NW for big waistband |

| 16 | Elastic for big waistband |

| 17 | Construction glue |

| 18 | Elastic glue |

| 19 | Wetness indicator glue |

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully automated, w...

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully automated, w...

This is a Machine for Making Sanitary Pads in Nicaragua. This machine cam produce four kinds of sanitary napkin, 245mm normal, 245mm ultra thin, 290mm no...

This is a full servo panty liner machine in designed for Middle Asia customer.It can produce 2 size of : 155mm,180mm. The stable speed is 900-1000 ppm. Th...

We've seen a significant improvement in production output and product quality since we started using the Baby Diaper Machine. Our customers love the result!Liam 2024-05-30

The reliability of the Baby Diaper Machine has given us peace of mind. We can fulfill orders on time without worrying about breakdowns or delays.Henry 2024-05-30

We've received positive feedback from parents who love the softness and snug fit of the diapers produced by this Baby Diaper machine. It's a win-win for everyone.Jack 2024-05-30

The Baby Diaper Machine efficient, reliable, and produces high-quality diapers consistentlyjone 2024-05-30