Sanitary napkin production line is an efficient and advanced manufacturing system that is designed to produce high-quality sanitary napkins for women. This prod...

1. Feminine Sanitary Napkin Machine Program System Servo driven, intelligent HMI touch screen man-machine interface 2. Tension System Tension control with buff...

1. Understanding your production needs. 2. Key features to consider. 3. Technical specifications. 4. Quality control and assurance. 5. Cost considerations. 6. S...

Introduction. 1. Regular Maintenance and Inspection. 2. Quality Control. 3. Efficient Inventory Management. 4. Optimize Production Efficiency. 5. Training and S...

Introduction. 1. Preparing the Installation Site. 2. Unpacking and Inspecting the Equipment. 3. Assembling the Machinery. 4. Connecting Utilities. 5. Testing an...

Introduction. Materials Used in Sanitary Napkin Production. Technology and Machinery. Quality Control. Conclusion....

1. Raw Material Preparation. 2. Core Formation and Absorbency Enhancement. 3. Packaging and Quality Control....

Regular Cleaning and Inspection. Proper Lubrication and Calibration. Staff Training and Maintenance Schedule....

Introduction. Streamlining Production with Automated Processes. Ensuring Product Quality and Hygiene Standards. Enhancing Cost-effectiveness and Sustainability....

Introduction. 1. Large-Scale Manufacturing. 2. Customization Options. 3. Efficient Material Utilization. 4. Quality Control. 5. Increased Productivity. 6. Impro...

1. Market Overview. 2. Technological Advancements. 3. Challenges and Opportunities....

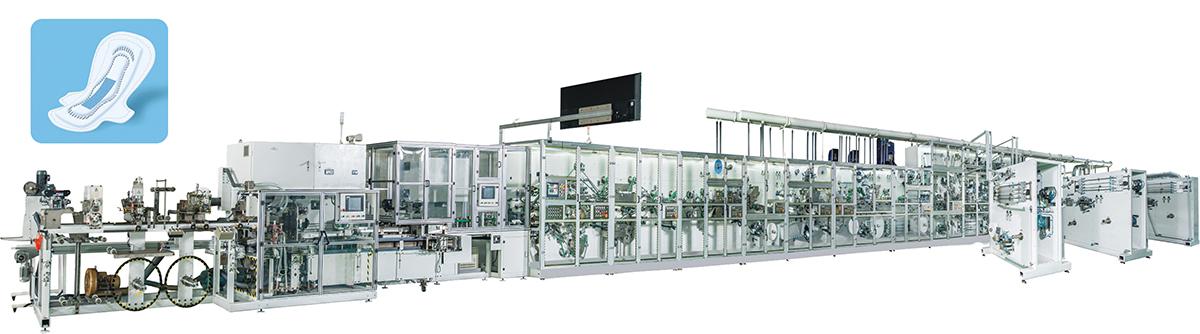

WSJ500 sanitary napkin production line semi-servo + automatic bagging machine is a production speed of 500 products per minute production line....

High quality Sanitary napkin production line Manufacturer Video...

Planned periodic maintenance refers to a maintenance method that is time-based, preventive and timely repaired according to the plan, including the maintenance,...

Pants sanitary napkin production lineprocessing process, there are many factors that cause the size of the parts error, which processing positioning error calcu...

Although the content of equipment inspection of sanitary napkin production line varies greatly depending on the type of equipment and working conditions, the in...

Sanitary Napkin Production Line in Argentina, this machine only can produce 240mm one size as per customer, stable working speed is 800ppm, the core is pulp ...

1. Adult Diaper Manufacturing Machine Program System Servo driven, intelligent HMI touch screen man-machine interface 2.Tension System Tension control with buffer system, autom...

1. Feminine Sanitary Napkin Machine Program System Servo driven, intelligent HMI touch screen man-machine interface 2. Tension System Tension control with buffer system, automatic web ...

A machine for making sanitary pads is a mechanical device that is used to produce feminine hygiene products. There are several key features that make this product effective and efficien...

This is Sanitary Pad Machine in Nigeria. The machine stable speed is 800pcs/min. This machine can produce two sizes of the sanitary pad, this machine also with stacker and two auto bag...

This is a Pamper Machine in Norway, with a stable production speed of 450pieces / min. The equipment is a customized equipment jointly developed with customers. The product is new type...

Baby diaper manufacturing machine will undergo strict inspection when leaving the factory....

Embrace the next generation of manufacturing with this groundbreaking pull-up diaper production line, where the industry's future begins. Capable of producing 800 units per minute, it ...