Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-07

Planned periodic maintenance refers to a maintenance method that is time-based, preventive and timely repaired according to the plan, including the maintenance, minor repair and overhaul of the production line of sanitary napkin production line. It does not need to deeply consider the state of the equipment and whether it needs to be repaired. The details are as follows:

This kind of maintenance form attaches great importance to planning, which is a repair plan based on the running state of sanitary napkin production line: that is, in the process of equipment inspection, for the equipment found abnormal, it is classified and queued according to the priority and degree of abnormality, and it is timely and appropriate to carry out repair, plan periodic maintenance, and pay great attention to prior detection, collect information, and carry out timely maintenance. First of all, it is necessary to formulate annual maintenance The general cycle schedule of minor repair and overhaul, and then arrange the work plan and acceptance method for each time according to the annual general schedule, including the machine number, maintenance time, maintenance content and technical conditions for handover and acceptance after maintenance.

Make a planned maintenance plan. On the one hand, reduce downtime and make full use of downtime to arrange plans for equipment maintenance;

On the other hand, try to consider the required maintenance as well as possible, break through the 8-hour working hour limit a day, carry out continuous repair operations, and reduce the maintenance downtime.

The arrangement of maintenance plan also requires moderate maintenance. Only the faulty parts need to be disassembled and repaired, and only the damaged parts need to be repaired and replaced, so as to further reduce the consumption of machine accessories and downtime, and improve the economic benefits and equipment operation rate.

Relying solely on sanitary napkin production line condition based maintenance will inevitably affect the long-term stable operation of the equipment and increase the risk of equipment "crash". Therefore, sanitary napkins making machine also needs to be carried out according to the plan, that is, planned periodic maintenance.

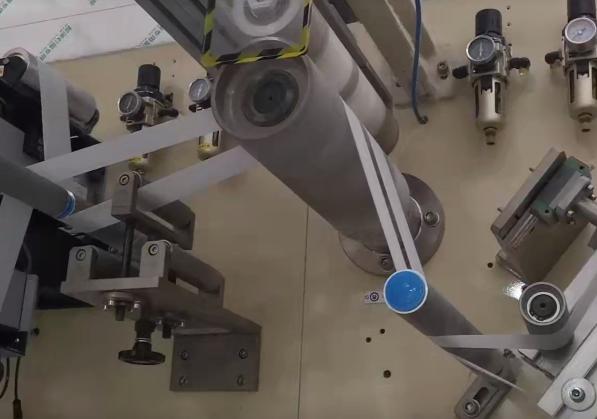

The maintenance of sanitary napkin production line mainly includes cleaning, fastening, adjustment, lubrication and corrosion prevention.

The Machinery Department of each project must strictly implement all maintenance work according to the maintenance manual and maintenance procedures of the best sanitary napkins machine, reduce the wear rate of parts, eliminate the hidden dangers of failure, and extend the service life of the machinery. The following work should be done:

(1) Routine maintenance

Focusing on cleaning, lubrication, inspection and fastening, routine inspection and maintenance shall be carried out before, during and after each shift. Routine maintenance is completed by the manipulator independently.

(2) Regular maintenance

According to the maintenance requirements of various mechanical equipment, corresponding regular maintenance must be carried out after reaching the specified working hours or specified time. Sanitary napkin production line is a machine for processing and producing various products of non-woven fabrics. The equipment mainly includes: bag machine, slitting machine, surgical clothes machine, filter cotton weaving machine, punching machine and other machines. It can process various specifications and shapes, with step-by-step length fixing, photoelectric tracking, computer automatic edge correction, accurate and stable.

To sum up, the best sanitary napkins machine must be properly maintained before it can be used normally.