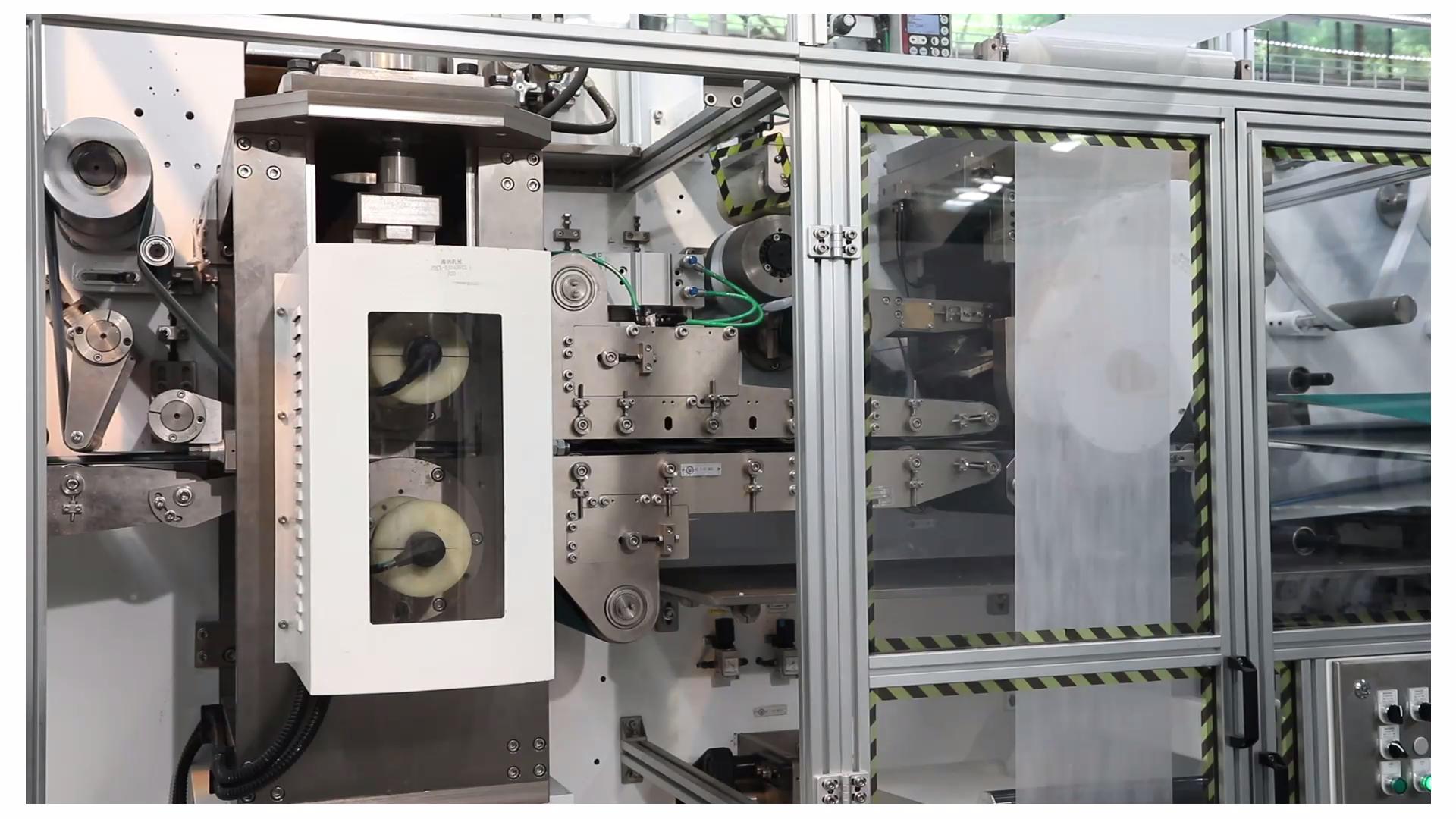

The sanitary napkins making machine is an innovative machine that has transformed the process of making sanitary napkins. The machine has several advantages in terms of its operation. Firstly, it is easy to operate, and even a person with no technical expertise can use it effectively. The machine has a user-friendly interface that allows operators to control and monitor its functions seamlessly.

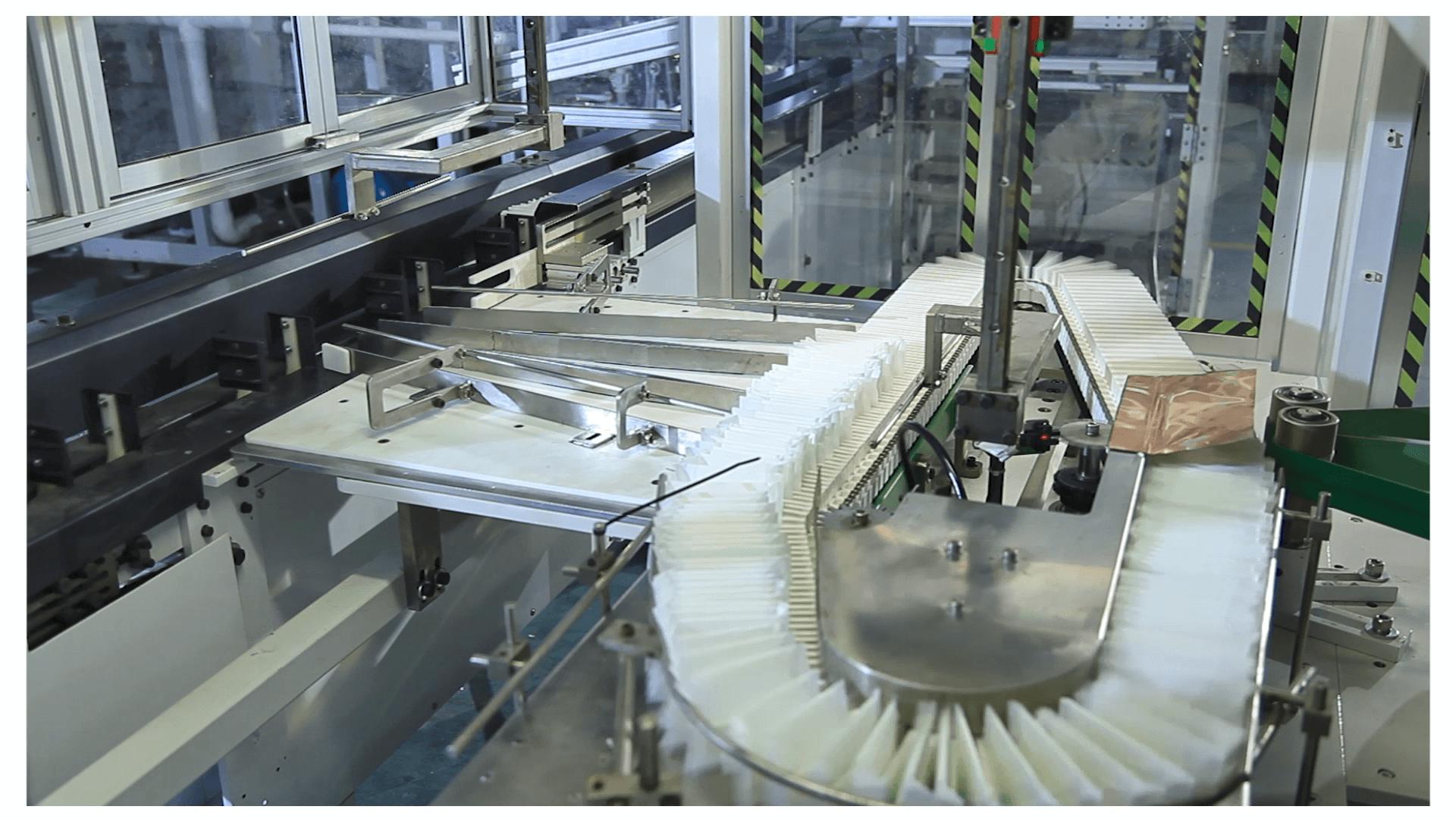

Secondly, the sanitary napkins making machine is highly efficient, and it can produce a large number of sanitary napkins in a short time. The machine is automated, and it can perform several tasks simultaneously, thereby reducing the production time and increasing the productivity of the operation. This makes it an ideal machine for manufacturers who need to meet large orders without compromising on quality and reliability.

Thirdly, the sanitary napkins making machine is cost-effective. It eliminates the need for manual labor, which reduces the production cost, and it requires minimal maintenance, which further saves on the operating cost. This means that businesses can save money on production while still maintaining high-quality standards.

Automatic Lady Pad Machine

|

Dimensions(L×W×H8) |

45m*10m*4m |

|

Design Speed: |

350ppm |

|

Stable Working Speed: |

250-300ppm |

|

Rejection Rate: |

≤4% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

400KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

95 tons |

1. Strengthen the maintenance and maintenance of daily Lady Pad Machine

The Lady Pad Machine is in a long-term operation state during the operation and production process, and it is easy to have hidden troubles. Maintenance and maintenance is to reduce the occurrence of failures.

2. Improve the management system and supervision mechanism

An effective management system and supervision mechanism is an important way to supervise the work behavior of technicians. Production enterprises should establish and improve the equipment management system and effective supervision mechanism, and implement the responsibility management system, and implement the responsibility contract system for the maintenance of Lady Pad Machine.

Automatic Menstrual Lady Pad Machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | Waist inner NW |

| 11 | Waist outer NW |

| 12 | Elastic for waist |

| 13 | Construction glue |

| 14 | Elastic glue |

| 15 | Wetness indicator glue |

It's a revolutionary product that has simplified my menstrual care routine.John 2024-05-31

The quality of the menstrual pants produced by this machine is top-notch.Luna 2024-05-31

Menstrual Pants Machine a one-time investment that pays off in the long run.Noah 2024-05-31

Menstrual Pants Machine to anyone looking for a more sustainable and cost-effective solution for managing menstruation.Dylan 2024-05-31