Lady pad machine is an innovative device designed to help women produce their own sanitary pads. It is a revolutionary product that addresses various concerns related to menstrual hygiene, such as affordability, accessibility, and environmental impact. The machine is compact and easy to use, enabling women to produce high-quality pads using locally-sourced materials. This device empowers women by providing them with a sustainable and cost-effective solution to menstrual hygiene management. Moreover, it promotes environmental sustainability by reducing the amount of waste generated from disposable pads. The lady pad machine is an ideal product for women in rural areas and developing countries, where access to menstrual hygiene products is limited or expensive. Overall, this product is a game-changer in the field of menstrual hygiene and empowers women to take control of their menstrual health.

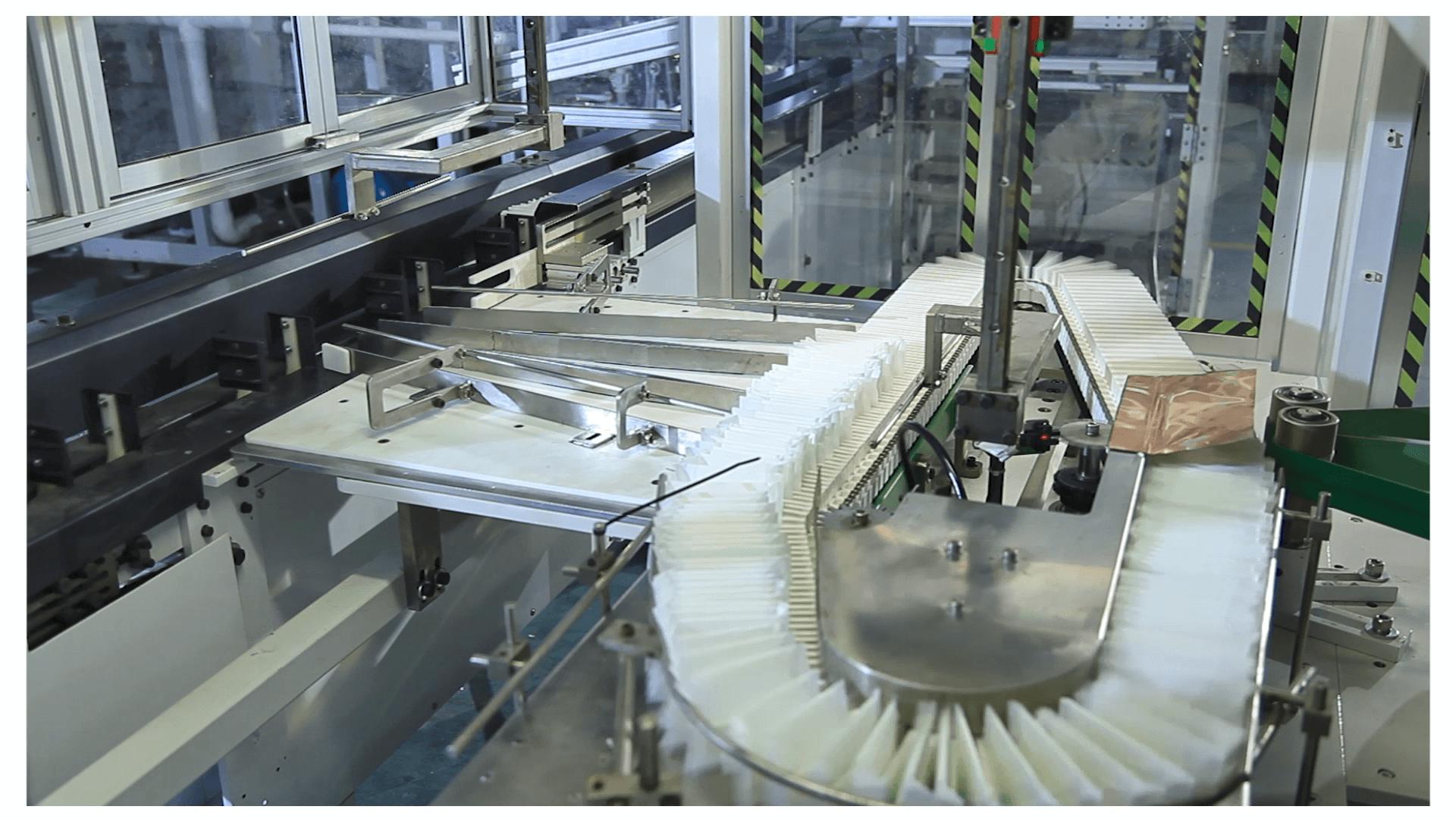

The Automatic Menstrual Pants Making Machine is a cutting-edge innovation designed to streamline the production of menstrual pants.

It combines advanced technology and efficient manufacturing processes to create high-quality, comfortable, and hygienic pants for women during their menstrual cycle. This machine is revolutionizing the feminine hygiene industry by automating the production process, ensuring consistent quality, and improving productivity.

Automatic Menstrual Pants Making MachineTechnical Features:

1. High Efficiency: The machine utilizes advanced automation technology to achieve high-speed production, significantly reducing labor costs and increasing output.

2. Precise Cutting: Equipped with precision cutting tools, the machine ensures accurate and uniform cutting of fabrics, resulting in perfectly shaped menstrual pants.

3. Intelligent Control System: The intelligent control system enables easy operation and seamless integration with other manufacturing processes, enhancing overall efficiency.

4. Adjustable Sizing: The machine allows for adjustable sizing options, accommodating different body shapes and sizes, providing a comfortable fit for every woman.

Automatic Menstrual Pants Making Machine Product Applications:

The Automatic Menstrual Pants Making Machine can be widely used in various industries related to feminine hygiene products, including sanitary pad manufacturers, textile factories, and women's health product companies. It provides a reliable and efficient solution for mass production of menstrual pants, meeting the increasing demand for high-quality and disposable period underwear.

Automatic Menstrual Pants Making Machine Main Functions:

1. Fabric Feeding: The machine automatically feeds the fabric into the production line, ensuring a continuous flow of materials.

2. Cutting and Shaping: Through advanced cutting mechanisms, the machine precisely cuts and shapes the fabric, creating well-fitting and comfortable menstrual pants.

3. Elastic Band Integration: The machine seamlessly integrates elastic bands into the pants, providing secure and comfortable support.

4. Folding and Packaging: The machine folds and packages the finished pants, ready for distribution and sale.

Automatic Menstrual Pants Making Machine Precautions:

1. Maintenance: Regular maintenance of the machine is necessary to ensure optimal performance and longevity. Follow the manufacturer's guidelines for cleaning, lubrication, and inspection.

2. Safety: Operate the machine in accordance with safety protocols and provide appropriate training to operators to prevent accidents and injuries.

3. Quality Control: Regularly inspect the output for any defects or quality issues. Make adjustments as necessary to maintain consistent product quality.

4. Material Selection: Use high-quality fabrics and accessories to ensure comfort, durability, and hygiene of the menstrual pants.

5. Compliance: Adhere to industry regulations and standards related to the production of feminine hygiene products to ensure the safety and effectiveness of the menstrual pants.

In conclusion, the Automatic Menstrual Pants Making Machine is a revolutionary solution that automates the production process of menstrual pants. With its high efficiency, precise cutting, and intelligent control system, it provides a reliable and efficient way to produce high-quality menstrual pants. By following the necessary precautions and guidelines, manufacturers can maximize the potential of this innovative machine and meet the growing demand for comfortable and hygienic menstrual products.

Automatic Menstrual Pants Machine

|

Dimensions(L×W×H8) |

45m*10m*4m |

|

Design Speed: |

350ppm |

|

Stable Working Speed: |

250-300ppm |

|

Rejection Rate: |

≤4% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

400KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

95 tons |

CLK350-lady sanitary pad machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | Waist inner NW |

| 11 | Waist outer NW |

| 12 | Elastic for waist |

| 13 | Construction glue |

| 14 | Elastic glue |

| 15 | Wetness indicator glue |

Menstrual Pants Machine to anyone looking for a more sustainable and cost-effective solution for managing menstruation.Dylan 2024-05-31

Menstrual Pants Machine a one-time investment that pays off in the long run.Noah 2024-05-31

Menstrual Pants Machine a great solution for busy individuals.Samuel 2024-05-31

Menstrual Pants Machine so convenient and easy to use, and it has made managing my period a breezeBenjamin 2024-05-31