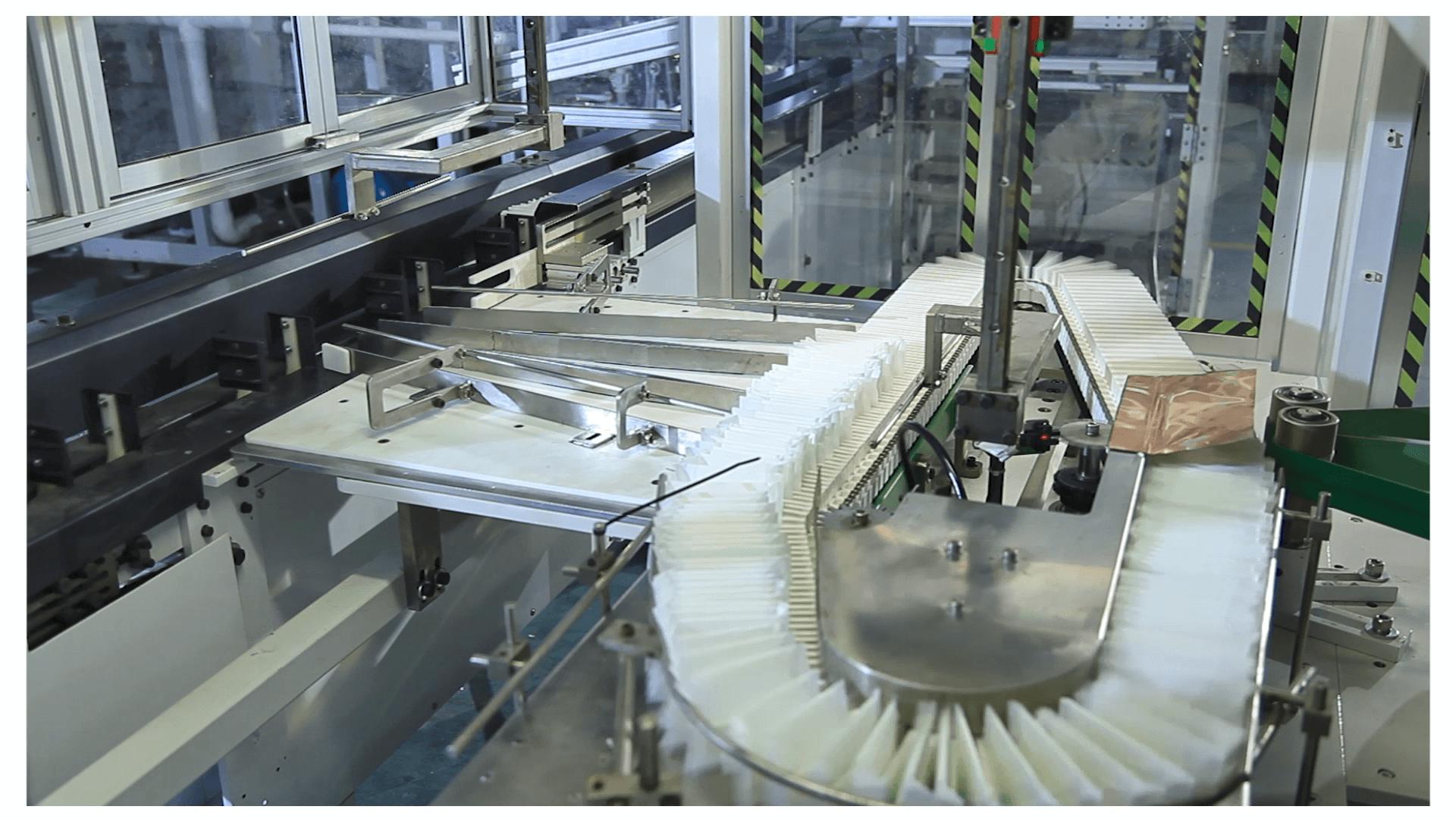

Sanitary napkins machine is a highly efficient and automated machine designed to manufacture sanitary napkins at a fast and consistent rate. Its state-of-the-art technology allows for precise and accurate control of size, shape, absorbency, and material usage, resulting in a high-quality product that meets the needs of modern women.

One of the key advantages of using a sanitary napkins machine is its ability to minimize human involvement in the manufacturing process. This ensures that there is uniformity in the napkins produced, while reducing the chances of errors and inconsistencies. The machine is also designed to be easy to operate, making it accessible to all employees on the production line.

Another benefit of using sanitary napkins machine is that it allows for customization of the product, meeting specific user requirements. The machine is designed to handle different types of materials, providing a range of options for the end product. This flexibility means manufacturers can offer a product that meets consumer’s needs, including thickness, softness, and absorbency.

Finally, the sanitary napkins machine is both cost-effective and environmentally friendly. It is designed to use minimal energy, reducing production costs and making it more affordable for end-users. Additionally, the machine is designed to minimize waste and uses recyclable materials, making it an eco-friendly alternative to traditional manufacturing methods.

Automatic Menstrual Pants Machine

|

Dimensions(L×W×H8) |

45m*10m*4m |

|

Design Speed: |

350ppm |

|

Stable Working Speed: |

250-300ppm |

|

Rejection Rate: |

≤4% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

400KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

95 tons |

Automatic Menstrual Pants Manufacturing Machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | Waist inner NW |

| 11 | Waist outer NW |

| 12 | Elastic for waist |

| 13 | Construction glue |

| 14 | Elastic glue |

| 15 | Wetness indicator glue |

Menstrual Pants Machine a one-time investment that pays off in the long run.Noah 2024-05-31

Menstrual Pants Machine to anyone looking for a more sustainable and cost-effective solution for managing menstruation.Dylan 2024-05-31

It's a revolutionary product that has simplified my menstrual care routine.John 2024-05-31

The quality of the menstrual pants produced by this machine is top-notch.Luna 2024-05-31