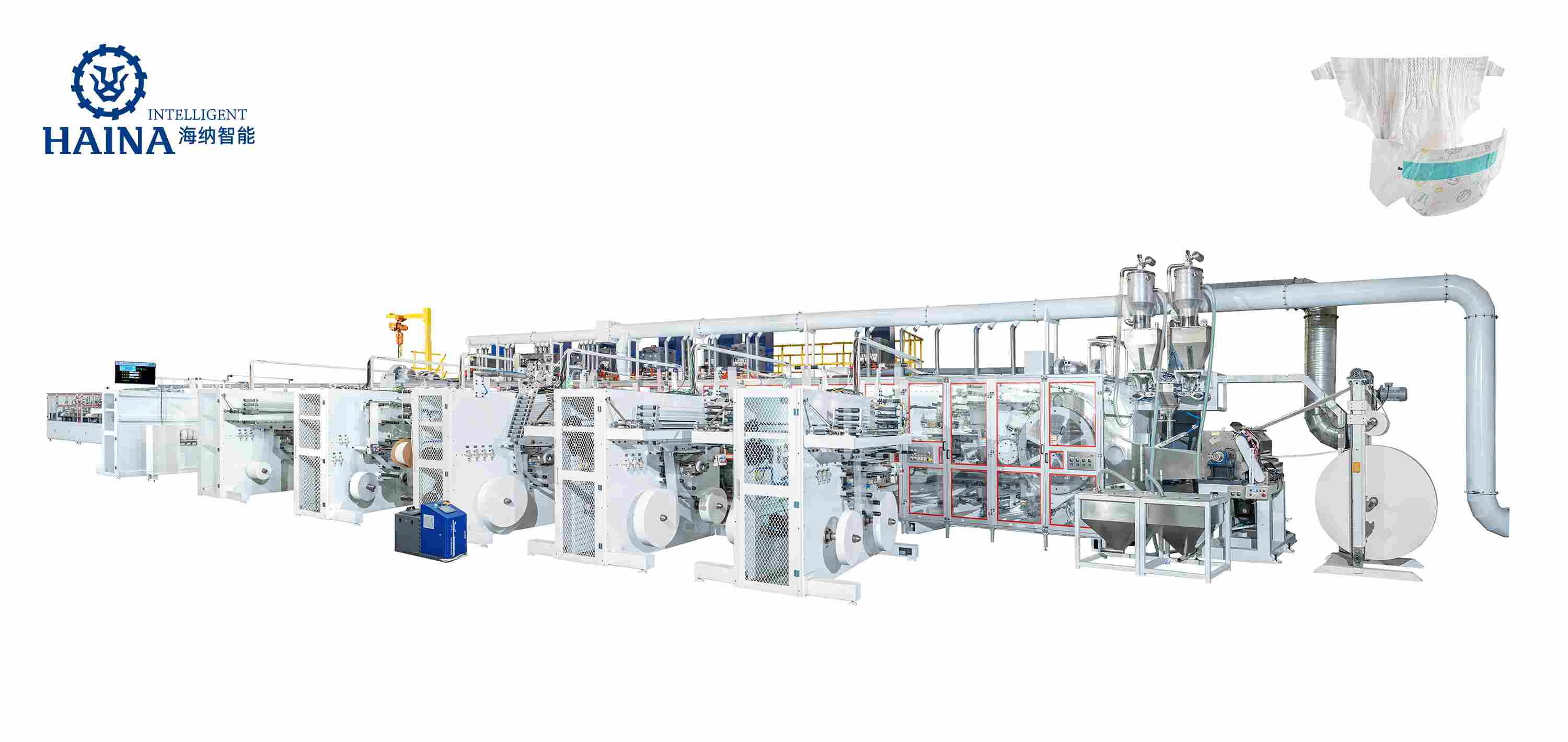

7.U-Shape Baby Diaper Production Line Customized Function Available

U-Shape Baby Diaper Production Line

|

Dimensions(L×W×H8) |

24m*4m*3.6m |

|

Design Speed: |

550ppm |

|

Stable Working Speed: |

450-500ppm |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

300KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

70 tons |

U-Shape Baby Diaper Production Line Description:

The U-Shape Baby Diaper Production Line is a state-of-the-art manufacturing system designed for the efficient and automated production of high-quality baby diapers. This production line incorporates advanced technology and engineering expertise to provide a comprehensive solution for diaper manufacturers.

Technical Features:

1. Automated Production: The U-Shape Baby Diaper Production Line is equipped with advanced robotics and automation systems, ensuring fast and accurate production processes. This minimizes human intervention and maximizes efficiency.

2. Flexibility: This production line offers a high level of flexibility, allowing for easy customization and adjustment according to specific manufacturing requirements. It can produce various sizes and types of baby diapers, meeting the diverse demands of the market.

3. High-Speed Operation: With its optimized design and cutting-edge machinery, the U-Shape Baby Diaper Production Line achieves exceptional production speeds, significantly increasing output capacity and reducing production time.

4. Quality Control: This production line integrates reliable quality control mechanisms, ensuring that each diaper meets strict quality standards. It includes automated inspection systems for detecting defects and irregularities in real-time, guaranteeing consistent product excellence.

Baby Diaper Production Line Application:

The U-Shape Baby Diaper Production Line caters to the needs of manufacturers in the baby care industry. It is suitable for producing disposable baby diapers, ranging from newborn sizes to larger sizes for toddlers. This production line enables manufacturers to meet the growing demand for high-quality diapers in both domestic and international markets.

Key Functions:

1. Material Handling: The U-Shape Baby Diaper Production Line efficiently handles various raw materials such as absorbent cores, non-woven fabrics, and elastic bands, ensuring smooth production flow.

2. Cutting and Shaping: The production line precisely cuts and shapes the materials into the desired diaper design, including waistbands, leg cuffs, and absorbent cores, ensuring optimal fit and comfort for babies.

3. Fusion and Assembly: The components are securely fused and assembled using advanced bonding techniques, resulting in leak-proof and durable baby diapers.

4. Packaging: Once the diapers are manufactured, the production line automatically packages them into convenient packs, ready for distribution and retail.

Precautions:

1. Maintenance and Inspection: Regular maintenance and inspection of the U-Shape Baby Diaper Production Line are essential to ensure optimal performance and prolong its lifespan. Follow the manufacturer's guidelines for servicing and inspecting the machinery.

2. Safety Measures: Operators should strictly adhere to safety protocols while working with the production line, including wearing appropriate protective gear and avoiding contact with moving parts.

3. Training: Proper training of operators is crucial to maximize productivity, minimize errors, and ensure safe operation of the U-Shape Baby Diaper Production Line. Provide comprehensive training programs to ensure proficiency in operating and troubleshooting the equipment.

4. Quality Assurance: Implement rigorous quality control processes throughout the production process to maintain consistent product quality. Regularly monitor and adjust the production parameters to meet quality standards.

In summary, the U-Shape Baby Diaper Production Line is an innovative and efficient solution for manufacturers in the baby care industry. With its advanced technology, flexibility, high-speed operation, and emphasis on quality control, this production line enables seamless production of high-quality baby diapers, meeting the demands of both domestic and international markets. Taking necessary precautions and ensuring proper maintenance will ensure optimal performance and safe operation of the production line.

U-Shape Baby Diaper Production Line

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | NW for laminating |

| 11 | Frontal tape |

| 12 | NW for S cut |

| 13 | Hook for S cut |

| 14 | Glue for S cut |

| 15 | NW for big waistband |

| 16 | Elastic for big waistband |

| 17 | Construction glue |

| 18 | Elastic glue |

| 19 | Wetness indicator glue |

1.Baby Pull-ups Diaper Making Machine Program System Servo driven, intelligent HMI touch screen man-machine interface 2. Tension System Tension control with buffer system, automatic web guiding ...

High Speed Full Servo Baby Diaper Machine (Big Waistband)...

Adult Diaper Making Machine Supplier in UAE, Haina Machinery attended in Chinese brand Goods Exhibition in UAE. In this exhibition we showed the machines...

This full servo baby diaper machineis the first set purchased by the customer from Haina. The design speed of this production line is 500 pieces and the...

The Baby Diaper Machine is easy to operate and requires minimal maintenance, saving us time and resources. It's definitely worth the investment.Ethen 2024-05-30

The Baby Diaper Machine efficient, reliable, and produces high-quality diapers consistentlyjone 2024-05-30

We've received positive feedback from parents who love the softness and snug fit of the diapers produced by this Baby Diaper machine. It's a win-win for everyone.Jack 2024-05-30

We've seen a significant improvement in production output and product quality since we started using the Baby Diaper Machine. Our customers love the result!Liam 2024-05-30