|

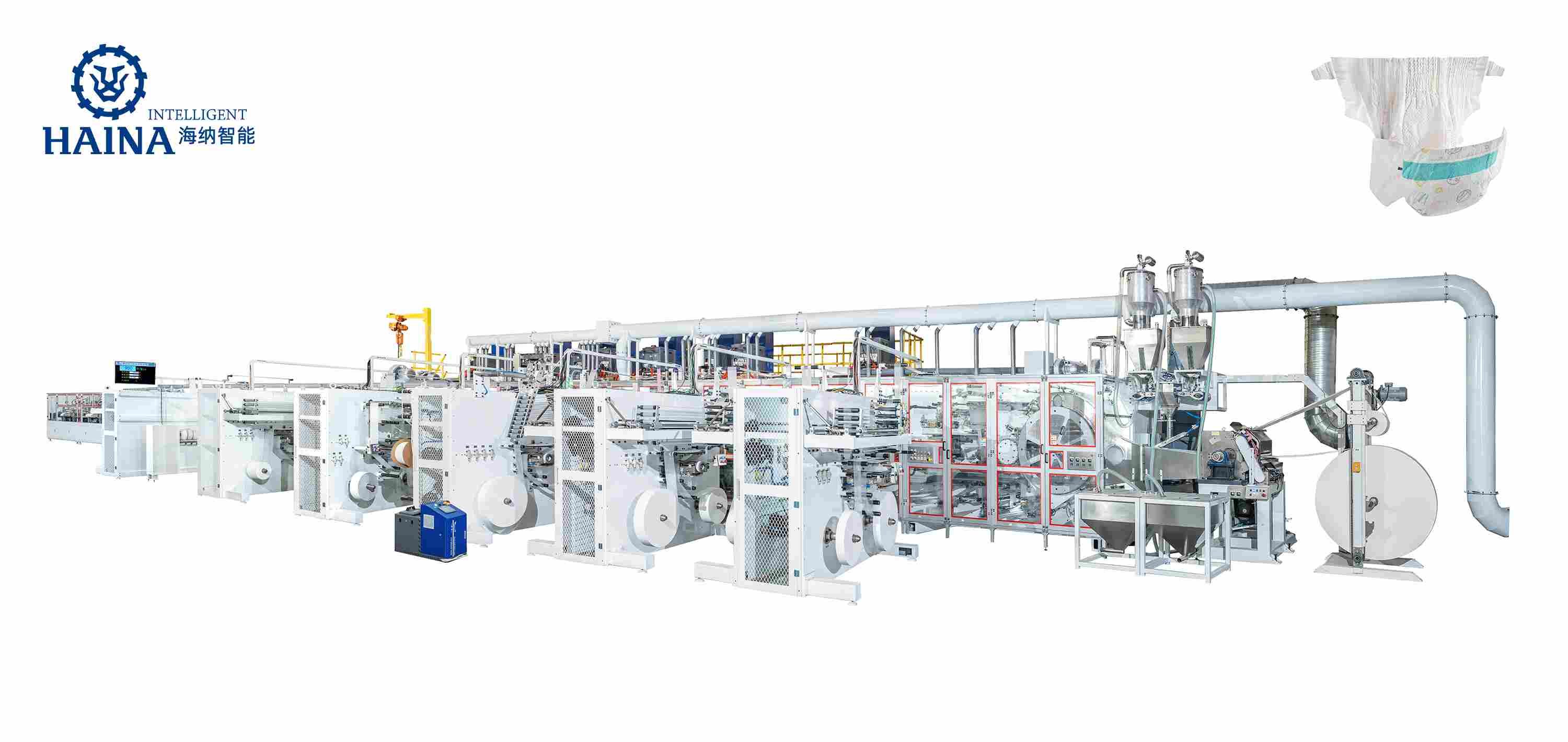

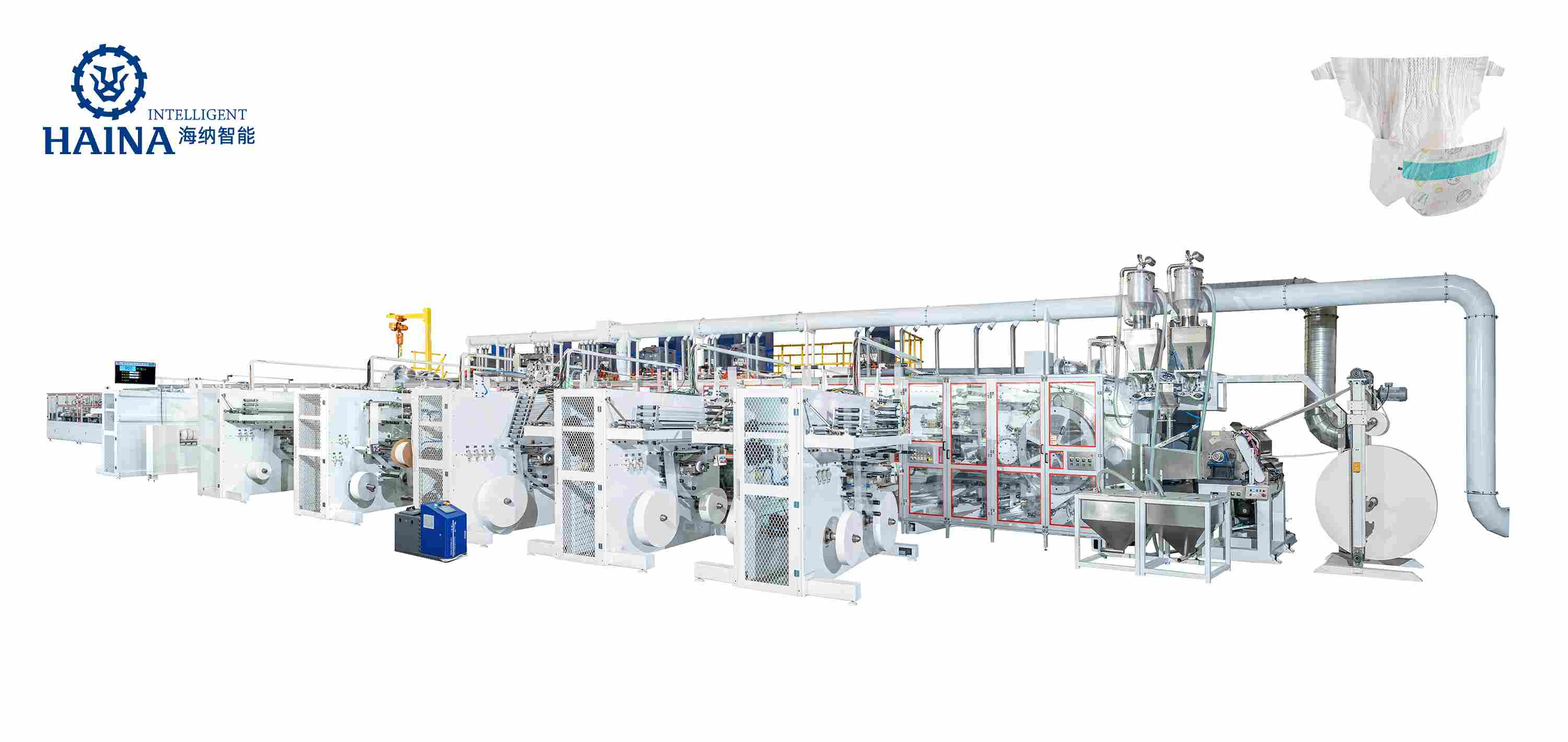

Dimensions(L×W×H8) |

38m*8m*5m |

|

Design Speed: |

800ppm |

|

Stable Working Speed: |

800/700 pcs |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

550KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

85 tons |

Full Surround Baby Diaper Machine maintenance and management

1. Regularly overhaul the Baby Diaper Machine and carry out maintenance operations. In this way, possible failures can be prevented.

2. The effective application of the post-event maintenance management method, specifically, to carry out corresponding repair work after the failure of the diaper machinery. If the equipment fails during the application process, it will affect the production and construction progress, and there are certain safety hazards. In addition, after the failure occurs, more problems will be caused, and even simple failures will become more complicated, so in the process of maintenance management, enterprises will need to spend more money.

Baby Diaper Machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | NW for laminating |

| 11 | Frontal tape |

| 12 | NW for S cut |

| 13 | Hook for S cut |

| 14 | Glue for S cut |

| 15 | NW for big waistband |

| 16 | Elastic for big waistband |

| 17 | Construction glue |

| 18 | Elastic glue |

| 19 | Wetness indicator glue |

1. T-Shape Ear Type Baby Diaper Machine Program System Servo driven, intelligent HMI touch screen man-machine interface 2. Driven System Servo drive, digital size change, ensure run synchronously...

1.Product structure: Upper lower tissue (or airlaid ), Cotton core (mix with SAP), ADL,PE flm, Frontal tape, Topsheet hydrophilic nonwoven, Leg cuff hydrophobic nonwoven, "S" cut side tape, Wai...

Automatic Baby Diaper Machine, with two functions to produce pulp type and ultra thin type for the market. The overseas market still prefer to use thick di...

Diaper Manufacturing Equipment in Burundi,this machine design speed is 600ppm for L size and stable working speed is 500ppm, can produce 5 sizes of baby pa...

We've received positive feedback from parents who love the softness and snug fit of the diapers produced by this Baby Diaper machine. It's a win-win for everyone.Jack 2024-05-30

This Baby Diaper Machine has streamlined our manufacturing process and allowed us to deliver diapers that exceed our customers' expectations in terms of comfort and absorbencyMason 2024-05-30

The Baby Diaper machine technical support provided by the manufacturer has been excellent, ensuring that our production runs smoothly without any hiccups.amy 2024-05-30

Our operational costs have decreased significantly, thanks to the efficiency of the Baby Diaper Machine. It's a cost-effective solution for any diaper manufacturer.Matthew 2024-05-30