Step 1: Preparation. Step 2: Machine Operation. Step 3: Maintenance and Quality Control....

1. Cleaning and Inspection. 2. Lubrication. 3. Calibration and Adjustment....

Introduction. Enhancing Production Efficiency. Ensuring Product Quality. Customization and Innovation. Conclusion....

Introduction. 1. Raw Materials. 2. Machine Design. 3. Quality Control. Conclusion....

Modern production relies more and more onequipment, and it is more and more urgent to fully grasp the technical statusof equipment. At the same time, the impact...

Mechanical management is an indispensable part of the normal operation of an enterprise. With the increasingly fierce market competition and the further deepeni...

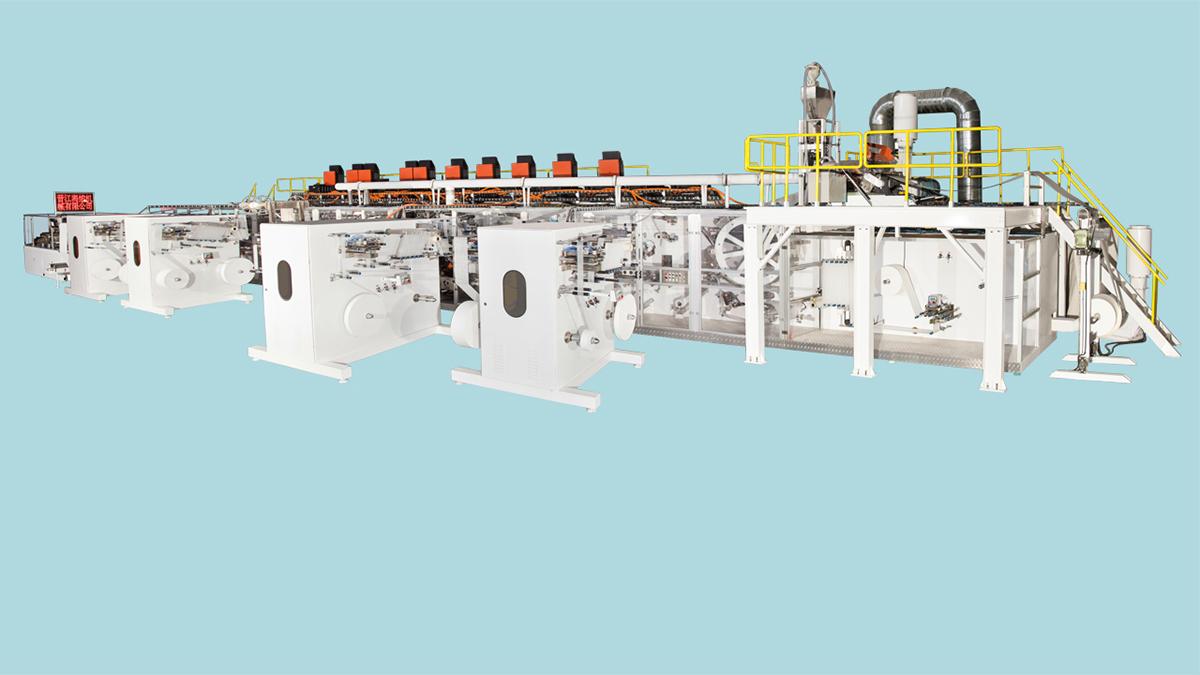

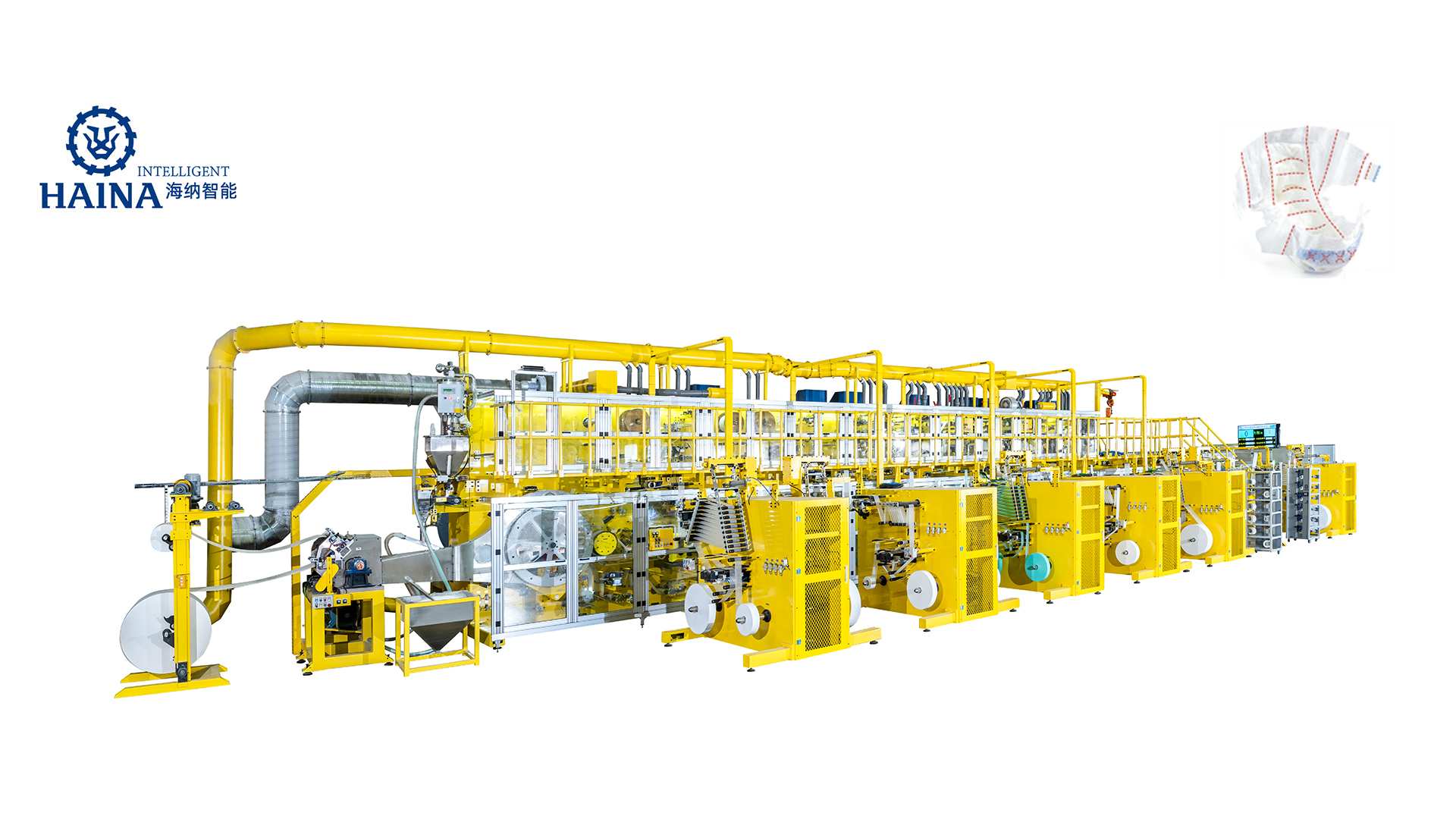

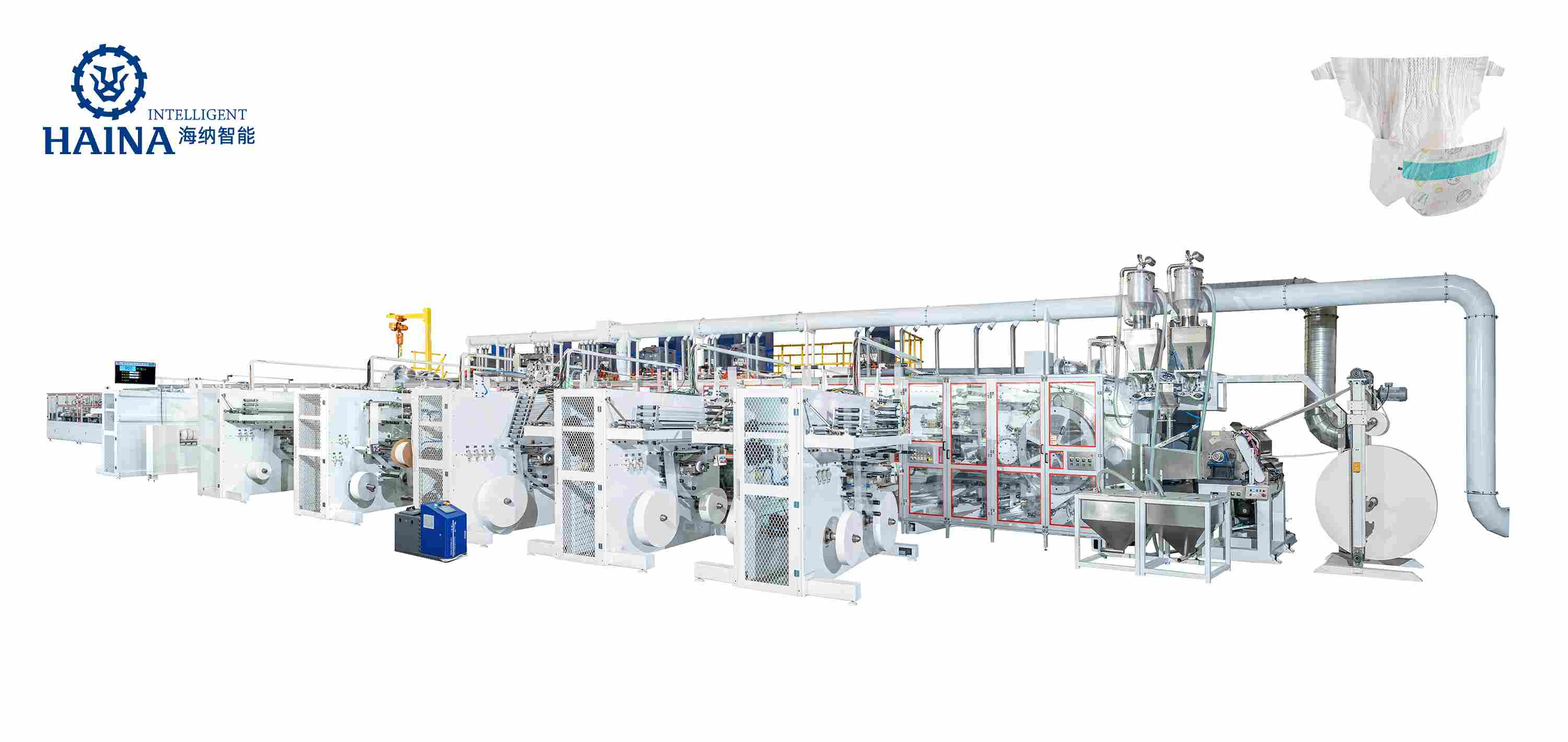

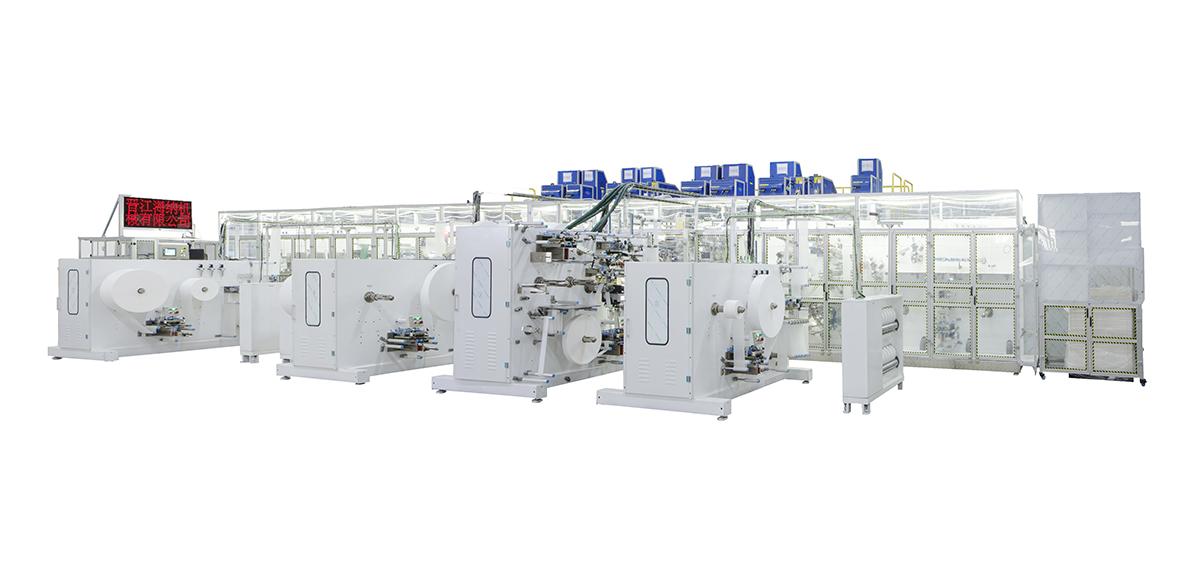

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully au...

1.Product structure: Upper lower tissue (or airlaid ), Cotton core (mix with SAP), ADL,PE flm, Frontal tape, Topsheet hydrophilic nonwoven, Leg cuff hydrophobic nonwoven, "S" cut side...

Overall size: 38mx8mx5m (for reference only), Driven system: Servo drive, digital size change, ensure run synchronously at full process.Safety system: Safety guard for operating side, e...

Thisis HAINA adult pant production line to one renowned customer in South Asia.They have many baby diaper machines from Haina, it is the first time for themto bring in Adult machine. ...

This is full servo adult pants machine for the customer from Korea. The machine stable speed is 260PPM. The customer purchased this machine from Haina machinery in 2021. The adult diape...