Modern production relies more and more on

equipment, and it is more and more urgent to fully grasp the technical status

of equipment. At the same time, the impact on product quality, safety and

environmental protection, and energy consumption is also increasing. As a major

country in the world's manufacturing industry, the contradiction between

advanced female diaper machine equipment and backward equipment management has

become increasingly prominent:

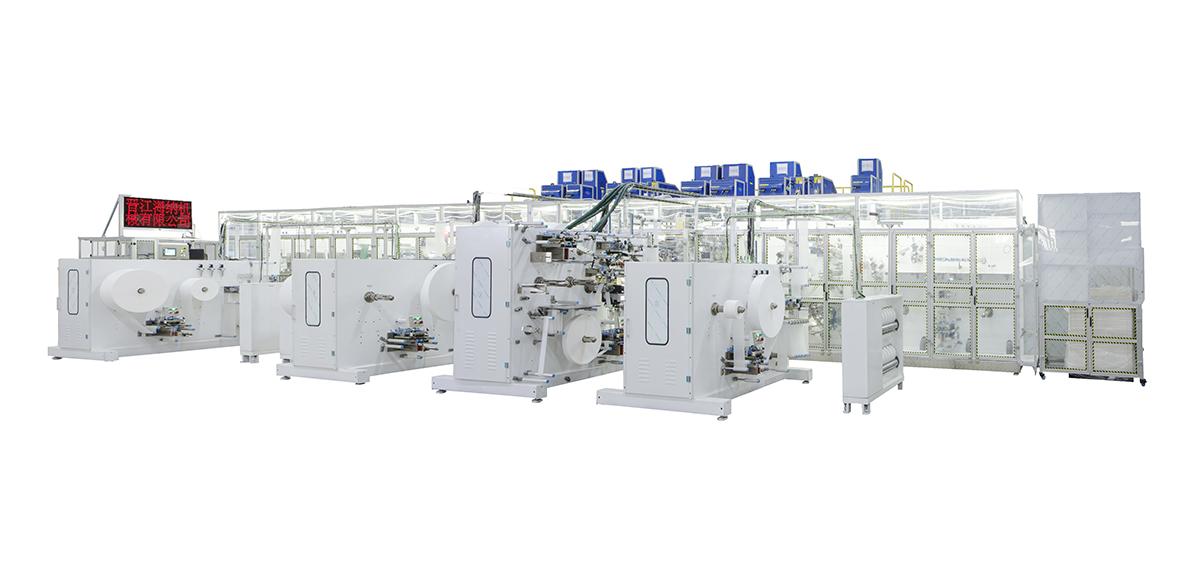

1.the new problems brought by the modern female diaper machine

Hyundai female diaper machine has the characteristics of large-scale,

high-speed, automation and intelligence. Large-scale production is highly

concentrated, so the loss caused by failure is much higher than that of small

machines, and large-scale machines are expensive and have a great impact on

product costs; the high-speed machine has brought some technical and economic benefits

to the production of enterprises. Some problems, such as the corresponding

increase in the energy consumption of the drive device, require higher

materials and automation; automation and intelligence increase the complexity,

increase the number of failures and the probability of failure, and bring

difficulties to the maintenance work.

2. female diaper machine full life cycle management platform

Compared with the traditional narrow-sense equipment management that focuses on

maintenance management, equipment life cycle management refers to the overall

consideration of the entire process of equipment planning, design,

manufacturing, purchase, installation, operation, maintenance, transformation,

updating, and scrapping.

So, how should modern enterprises optimize management methods to ensure the

maximization of asset value and the optimization of operational efficiency

during its life cycle?

① Digitization, so that the whole

management process can be traced

diaper machine the digitization of the whole life cycle management platform, in

addition to being able to quickly view all kinds of information that

traditional management software can provide, such as purchase date, suppliers,

maintenance records, maintenance records, maintenance cycles, etc. through

computers, ipads and other devices; it can also achieve All kinds of process

information can be traced throughout the whole process, such as working

condition information for recording workpiece information and processing

parameters, and status information for health assessment such as influencing

factors, process parameters, and environmental parameters.

② Intelligent, active maintenance

management

diaper mechanical in the whole life cycle management work, maintenance

management is a very important part. Benjamin Franklin once said that 100%

remediation is far better than 100% prevention. It can be seen that maintenance

management should first be preventive maintenance. Through preventive analysis

and early warning, on the one hand, it can help maintenance technicians to

arrange some important preventive maintenance measures in advance to prevent

the occurrence of downtime; on the other hand, through intelligent scheduling

of preventive maintenance, enterprises can have sufficient time Prepare for an appliance

upgrade or update.

③ Visualization simplifies management

The visualization of the full life cycle management platform, including visual

modeling, visual installation management, visual ledger management, visual

inspection management, etc., is represented by geometric modeling of enterprise

devices, which can display its shape intuitively, truly and accurately ,

distribution, operating status, and at the same time bind the model to

real-time, archives and other basic data to achieve rapid positioning and basic

information query in 3D scenes.

In short, a complete female diaper machine management platform needs to cover

the management of the whole life cycle, and needs to have the characteristics

of digital, intelligent and visual integration.