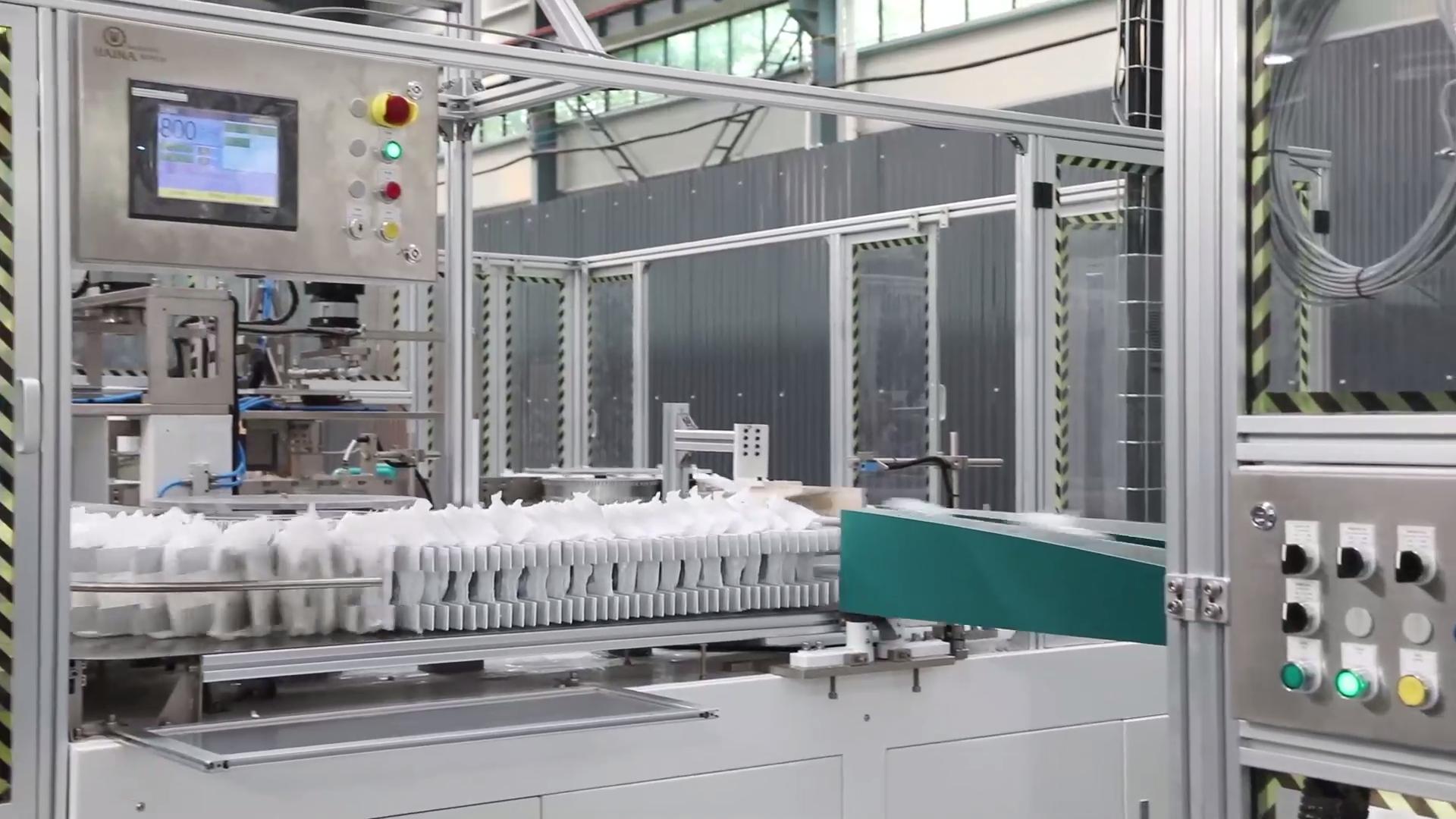

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-12

Best diaper making machine is a modern high-tech product, which is a complex of microelectronic technology, automation technology, computer technology and intelligent technology. Due to the advanced technology, complex structure and high intelligence of machinery and equipment in the process of operation, in the process of maintenance of machinery and equipment, maintenance technology, maintenance theory and means are very different from traditional machine maintenance. Faced with this situation, it is necessary for maintenance personnel to improve the development process of the times, master advanced maintenance technology principles and fault detection technology, and ensure the stable operation of best diaper making equipment.

best diaper making machine. On-site maintenance is to diagnose the faults of the machinery and equipment (mainly the machine parts), find the faulty parts, and replace them with corresponding normal spare parts to restore the normal operation of the machine. The key to this process is diagnosis, that is, to detect the system or peripheral circuits, determine whether there is a fault, and point out the exact location of the fault for fault location. From the positioning of the whole machine to the patch panel, in some cases, even to the components. This is the main part of the whole maintenance work.

First, a preliminary diagnosis. When the best diaper making machine fault site data is relatively comprehensive, the location of the fault can be judged through data analysis, or the interface signal method can be used to make a preliminary diagnosis of the fault in combination with the fault phenomenon, and then check each part one by one according to the specific characteristics of the fault. make a preliminary diagnosis. In the actual fault diagnosis process, sometimes only one method can be used to diagnose the fault, and sometimes it is necessary to comprehensively apply multiple detection methods to diagnose the fault. The diagnosis and identification of various fault points mainly depend on the operating characteristics of the faulty equipment and the depth of structural faults; secondly, alarm processing.

best diaper making machine Usually, system alarms caused by transient faults can be eliminated by hardware reset or by closing the system power supply. If the fault still exists after the initialization reset, the hardware needs to be detected and diagnosed. Change parameters and programs. System operating parameters are the main criteria for determining the operating capability of the system. If there is an error in the parameter setting, some functions will not be able to start normally. At the same time, sometimes a program error will cause a shutdown failure. For this, the quick search function of the system can be used. Check the cause of the failure. In the process of troubleshooting and maintenance, adjustment is the simplest and most widely used troubleshooting method. The system failure is solved by adjusting the potentiometer, and the optimal adjustment method is to adjust the servo drive system and the driven The comprehensive adjustment method of the mechanical system to achieve the best matching.

Best diaper making machine It is easy to have problems, and the maintenance of mechanical equipment has a direct impact on the overall quality. Therefore, it is necessary to strengthen the maintenance and maintenance of machinery. Improve the attention of managers to mechanical maintenance work, so as to effectively improve the technical level of mechanical equipment maintenance. In addition, it is necessary to strengthen the supervision of mechanical maintenance to improve work efficiency, so as to achieve better mechanical maintenance technology. develop.