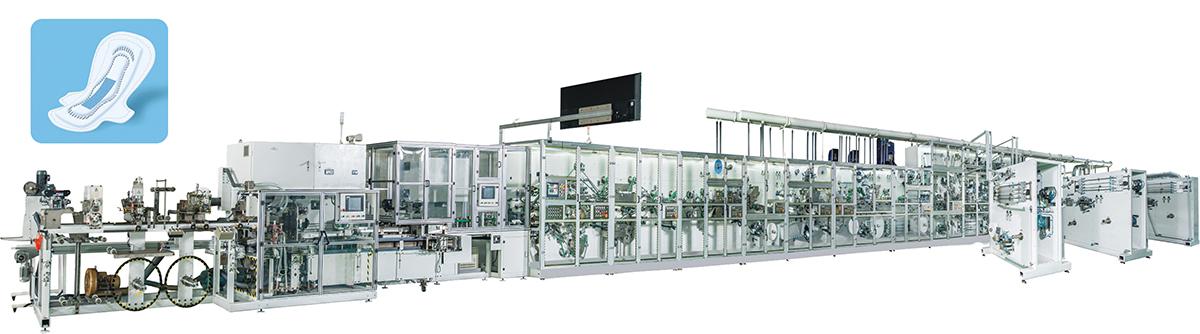

1. Feminine Full Automatic sanitary napkin production line Program System

Servo driven, intelligent HMI touch screen man-machine interface

2. Tension System

Tension control with buffer system, automatic web guiding system, to ensure materials stable working at zero speed splice.

3. Driven System

Servo drive, digital size change, ensure run synchronously at full process.

4. Driven System

Servo drive, digital size change, ensure run synchronously at full process.

5. Safety System

Safety guard for operating side, emergency stop switch, security identifier, safety pull wire at driven side.

6. Auto Pack System

Auto stacker and Packaging machine to be defined by customer need.

7. Web Guiding System

BST ,Germany/FIFE, USA

8.Feminine Napkin Machine+Auto Bagger Customized Function Available

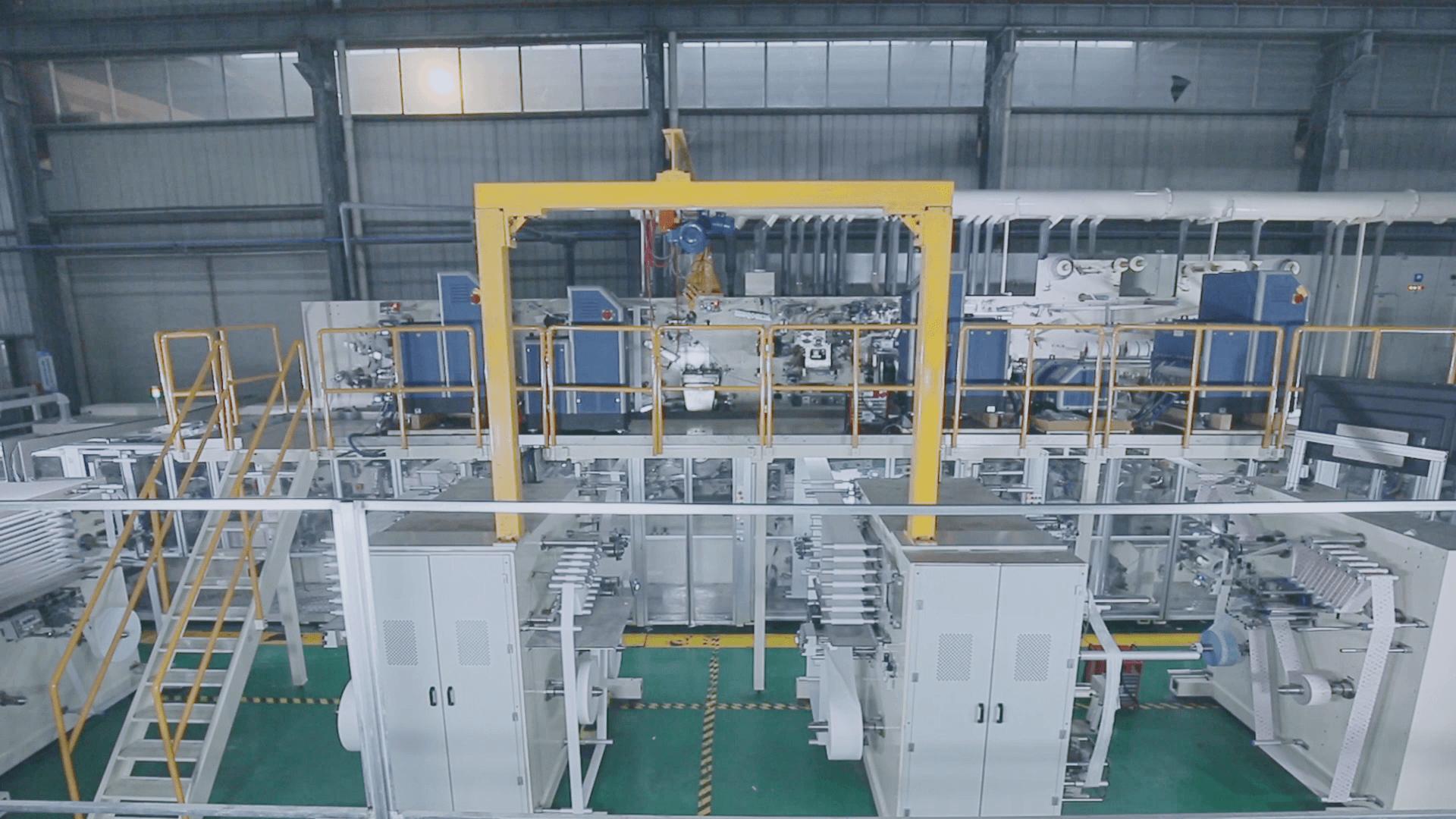

Full Automatic sanitary napkin production line

|

Dimensions(L×W×H8) |

30m*6m*3m |

|

Design Speed: |

1000ppm |

|

Stable Working Speed: |

800-900ppm |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

220KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

55 tons |

Although the sanitary napkin production line has high productivity, the operation of the equipment depends on the effective cooperation of each component. Any damage to the component may cause the equipment to operate abnormally and cause production to stop.

Due to the high cost of equipment safety management and maintenance, some small and medium-sized enterprises often ignore the issue of safety management, and wait until the failure will cause production to stagnate. Lack of daily safety production management, therefore lack of effective operation and fault records, once a fault occurs, the problem cannot be accurately found, and the maintenance time will be increased.

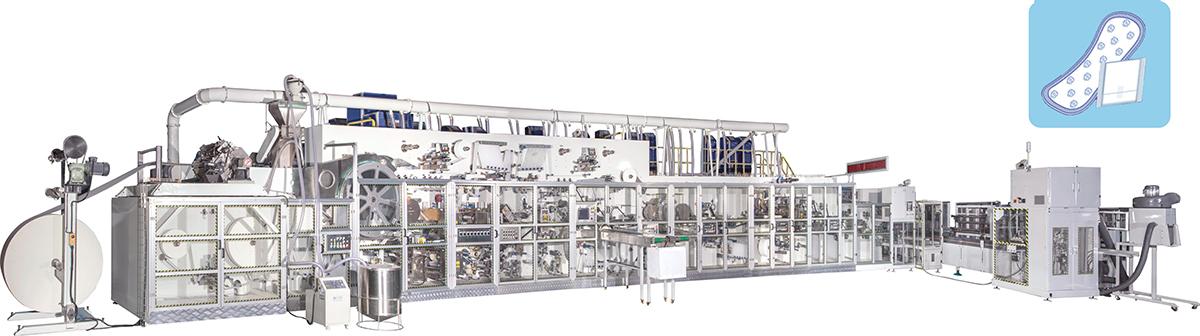

Feminine sanitary napkin production line

| No. | Raw materials |

| 1 | Topsheet(NW or PPF) |

| 2 | Fluff pulp |

| 3 | SAP |

| 4 | ADL N.W. |

| 5 | Tissue |

| 6 | Backsheet |

| 7 | Back release paper |

| 8 | Wings release paper |

| 9 | Pouch film |

| 10 | Easy tape |

| 11 | Air laid paper |

| 12 | SAP Paper |

| 13 | Hydrophobic N.W. |

| 14 | Construction glue |

| 15 | Position glue |

1. Feminine Full Automatic sanitary napkin production line Program System Servo driven, intelligent HMI touch screen man-machine interface 2. Tension Syst...

1.BestSanitary Pads Machine+Auto BaggerProgram System Servo driven, intelligent HMI touch screen man-machine interface 2. Tension System Tension control w...

A sanitary napkin making machine is an essential device in the manufacturing industry that produces feminine hygiene products. It is a highly efficient and...

The support team behind the Feminine Napkin Machine is top-notch,They provided excellent training and assistance when we needed itLaura M 2024-05-31

I love how easy it is to operate the Feminine Napkin Machine. It has increased our production capacity significantlyAmanda K 2024-05-31

The Feminine Napkin Machine is a game-changer for our business. It's efficient, reliable, and produces high-quality products consistentlyRachel W 2024-05-31

The quality of the feminine napkins produced by this Feminine Napkin Machine is unmatched. Our customers have given us great feedback since we made the switchEmily T 2024-05-31