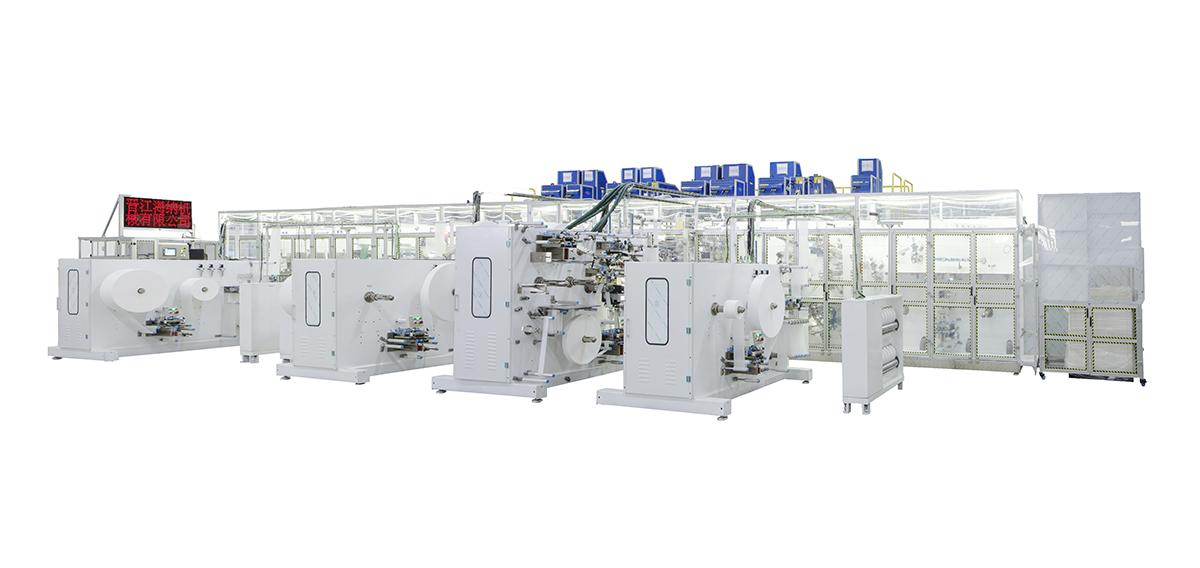

U-Shape Baby Diaper Production Line

|

Dimensions(L×W×H8) |

38m*8m*5m |

|

Design Speed: |

800ppm |

|

Stable Working Speed: |

800/700 pcs |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

550KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

85 tons |

Full Surround Baby Diaper Machine maintenance and management

1. Regularly overhaul the Baby Diaper Machine and carry out maintenance operations. In this way, possible failures can be prevented.

2. The effective application of the post-event maintenance management method, specifically, to carry out corresponding repair work after the failure of the diaper machinery. If the equipment fails during the application process, it will affect the production and construction progress, and there are certain safety hazards. In addition, after the failure occurs, more problems will be caused, and even simple failures will become more complicated, so in the process of maintenance management, enterprises will need to spend more money.

Baby Diaper Machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | NW for laminating |

| 11 | Frontal tape |

| 12 | NW for S cut |

| 13 | Hook for S cut |

| 14 | Glue for S cut |

| 15 | NW for big waistband |

| 16 | Elastic for big waistband |

| 17 | Construction glue |

| 18 | Elastic glue |

| 19 | Wetness indicator glue |

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully automated, w...

The disposable nappy machine is an advanced piece of equipment that is designed to produce high-quality disposable nappies efficiently. The machine offers several product features and functional ...

This Adult Pant Making Machineis able to produce adult pant in three sizes, size M/L/XL. Stable working speed 300pcs/min for M size.Compared with other adu...

Nappy Making Machine in Monaco, this machine can produce four sizes of baby diaper, S/L/L/XL, stable working speed for M size is 450pcs/min. This machine c...

The Baby Diaper machine's flexibility allows us to customize diaper designs according to market trends, giving us a competitive edge. Our customers appreciate the variety.Carter 2024-05-30

We've seen a significant improvement in production output and product quality since we started using the Baby Diaper Machine. Our customers love the result!Liam 2024-05-30

With the Baby Diaper Machine, we've been able to expand our product line and meet the growing demand for baby diapers. Our customers are happy, and so are weLiam 2024-05-30

The Baby Diaper Machine efficient, reliable, and produces high-quality diapers consistentlyjone 2024-05-30