"Digital transformation is the general trend. Enterprises should start from the most basic data and collect data in many aspects such as operation, operation, and market analysis. Hygiene products enterprises should consolidate their core business, not blindly expand, but strengthen cooperation, build core technologies, establish Brand, seize the core market and cultivate meticulously." Previously, Cao Zhenlei, director of the tissue paper professional committee of the China Paper Association, publicly stated.

At the recently held BRICS Industrial Internet and Digital Manufacturing Development Forum, Lin Yisu, Director of Health Products Production and Innovation Center of Hengan Group Health Products Division, introduced Hengan Group's "smart" manufacturing upgrade strategy.

Digital manufacturing is the only way for Weipin enterprise brand building and large-scale production

The e-works Research Institute predicts that in the next five years, more than 57% of enterprises will focus on digital/intelligent transformation, and more than 45% of enterprises will invest more than 100 million yuan in smart factory construction.

It can be seen that smart factories have become the hub and core of China's manufacturing transformation, and more and more companies are accelerating their digital transformation and upgrading. Under the wave of digitalization, the hygiene products industry has shown its "explosive power" under the new market opportunities with the improvement of social civilization and the superposition of consumption upgrades. Globally, women's own consumption accounts for more than 60% of the total consumption every year.

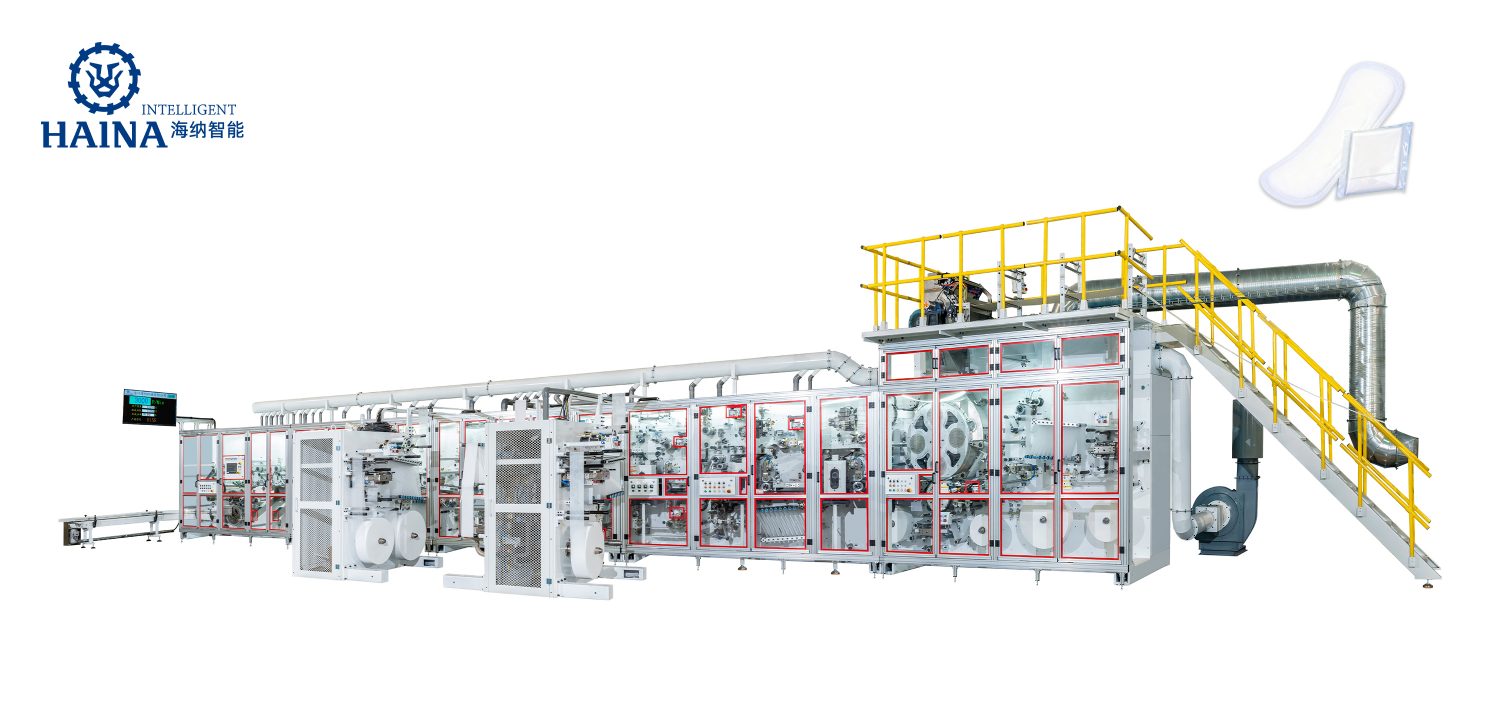

Huge consumer demand is driving the trillion-level hygiene product market, and the industry is facing AB: on the one hand, new opportunities for development are ushered in, and on the other hand, competition is fierce, and enterprises urgently need to break the domination of foreign brands in the high-end market. How can brands interact with consumers to extend new growth opportunities? Digital manufacturing is the only way for brand building and large-scale production, which can effectively achieve transparent management, improve product quality and production efficiency.

According to the statistics of the Household Paper Professional Committee, the market size of my country's absorbent hygiene products will reach 121.40 billion yuan in 2020, an increase of 4.2% over 2019. "Faced with strong market demand and fierce competition, Hengan Group needs to improve product quality and consumer awareness, break the domination of foreign brands in the high-end market, build brands to occupy the market, and effectively reduce costs." Lin Yisu said.

Intelligent hygiene products enterprises have become the "best choice" for industry development

In the era of Industry 4.0, "new technologies, productivity, and business models" have become the three major drivers. Lin Yisu believes that the upgrading and transformation of Industry 4.0 is inseparable from lean production. The core idea is to achieve rapid product delivery through "elimination of waste". Only in manufacturing engineering design and digital upgrade planning, enterprises can fully consider the principle of lean production. It is only by integrating the concept design of lean production into the operation system and eliminating wasteful functions that it is possible to make the Industrial Internet and digital manufacturing more efficient.

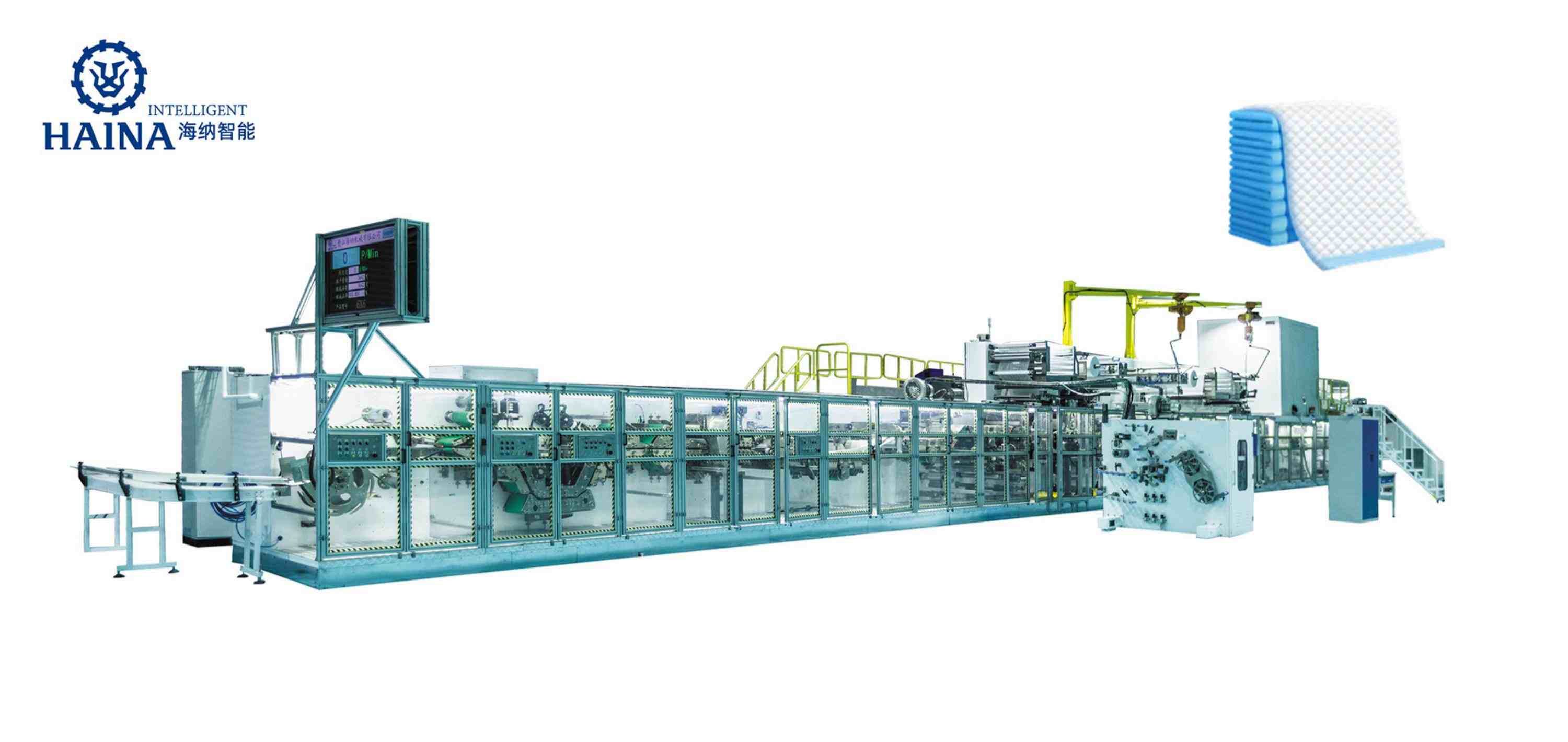

The information IoT system includes three core themes: one is to build a "smart factory", establish intelligent production systems and processes, and networked distributed production facilities; The application of a new generation of intelligent production technology such as human-computer interaction in the industrial production process; the third is to realize "intelligent logistics", through the Internet, Internet of Things, logistics network, integrate logistics resources, and give full play to the efficiency of existing logistics resource suppliers , while the demand side can quickly obtain service matching and logistics support.

In Lin Yisu's view, intelligent enterprises have become the "best choice" for the development of the industry, and automation and informatization are the foundation of intelligent enterprises, which cannot be separated from these "new infrastructures": PLM product life cycle management, ERP enterprise resource planning, lean Produce MES manufacturing execution system, Auto field equipment control system, WMS automated warehouse management system. At the same time, top-level design is also crucial. Digital transformation touches deep business changes. Once an enterprise lacks effective planning, the transformation can easily be shelved.

In order to better face the parallel market changes of "crisis and opportunity", as one of the earliest companies to enter the Chinese sanitary napkin market, Hengan Group began to plan how to "intelligently" break through as early as 2013, digitizing Chunjiang plumbing, and pioneering prophet!

Hygiene enterprise Hengan Group builds a new manufacturing model

Hengan Group was established in 1985. It owns well-known brands such as Xinxiangyan, Qidu Space, and Anerle. It is one of the most popular brands in Chinese families. Over the past 37 years, Hengan Group has built the reputation of "Made in China" with its national brand, leading health products to the world; with high-end quality, it has carried the banner of "new domestic products" to help traditional classics rejuvenate; with the industry mission of "guardian" The responsibility of the "owner" and practice green, low-carbon and sustainable development.

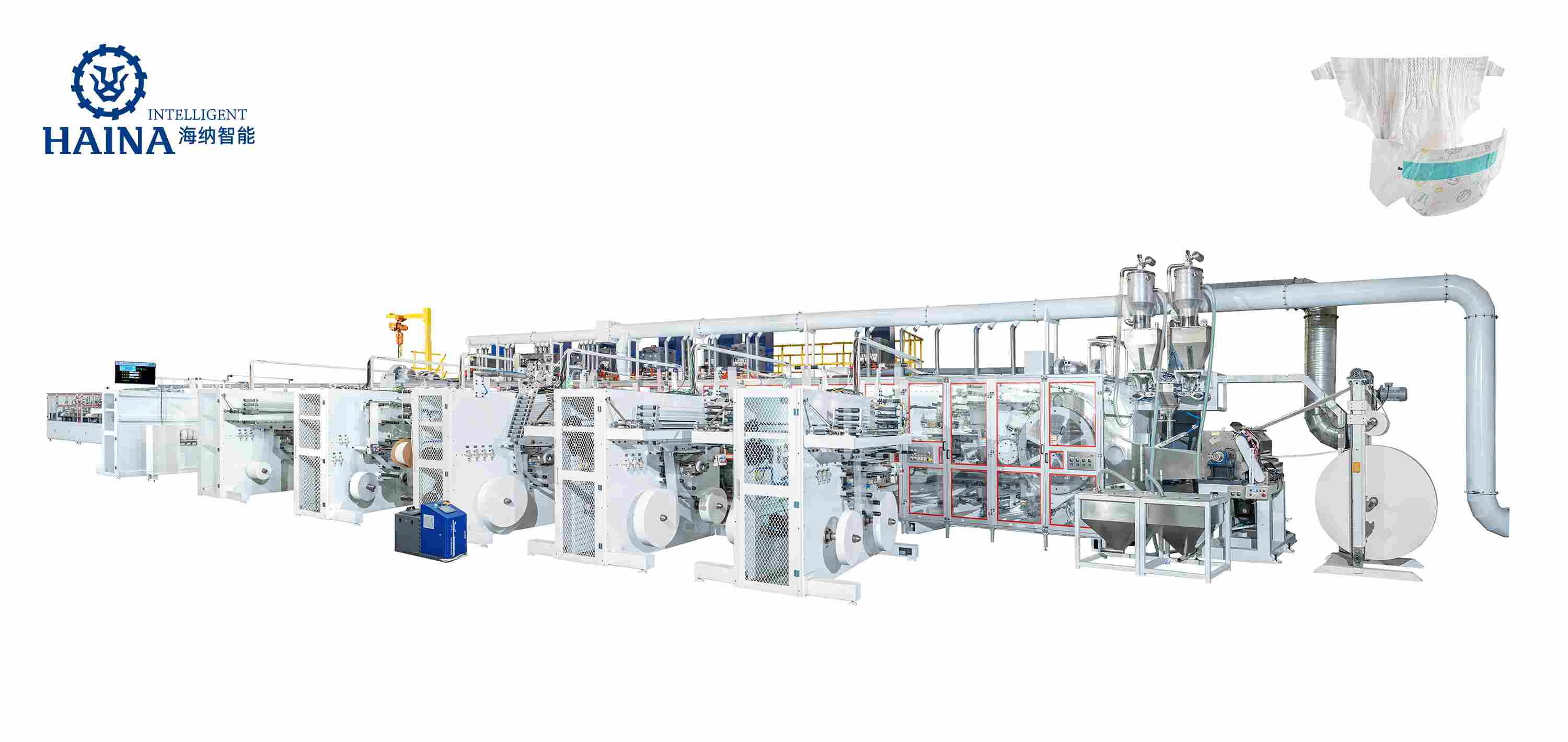

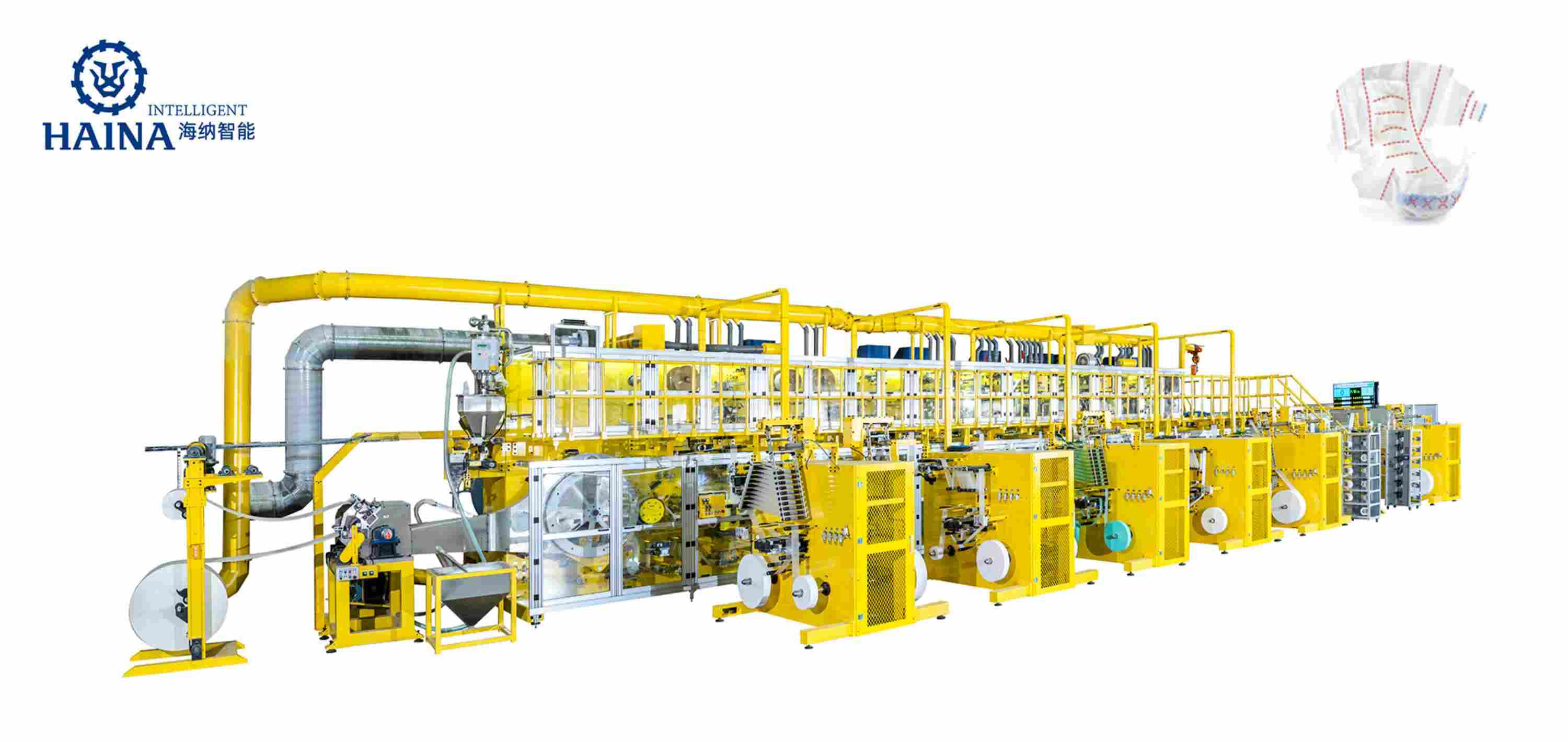

Based on the "smart" manufacturing upgrade strategy, Hengan Group has built a new manufacturing model. The project scope covers architecture design, data collection, production IoT, data traceability, short-board breakthroughs, collaborative integration, and platform monitoring. It not only builds a digital workshop system as a whole, but also From the warehousing of raw materials, to the monitoring of the whole process of production, packaging and warehousing of 20 stations, and at the same time multi-dimensional monitoring data, an industrial big data platform is formed, and a production process IoT and quality traceability system is built to realize high-speed process manufacturing production line control, etc.

Hengan's lean production MES process is reformed and sorted through four levels, covering business, operating rules, data, and hardware rectification, building a digital platform for group manufacturing, realizing an enterprise-level unified platform through data-driven management, and driving business transformation with the help of data operations. , the construction of an all-round digital collaborative intelligent manufacturing factory.

What has digitization brought? Focusing on the development axis of digital transformation, the digitalization of Hengan Group not only supports the business improvement and improvement in the manufacturing field, but also deepens organizational reform and promotes the improvement of the manufacturing system in digitization, lean improvement, equipment automation, process technology, etc., and gives full play to the expertise of the expert group. Wisdom and value, and carry forward the fine style of "comparing, learning, rushing, helping, and surpassing".

After laying the cornerstone of Industry 4.0, coupled with the combination of lean management and digitalization, Hengan has established a standardized production management system of lean "four possibles" that can be measured, analyzed, improved and replicated.

"Talent protection is very important when hardware and software are available, so the requirements for technicians and managers are higher, but everything is inseparable from lean production. The standards of lean management and digital transformation are very important, if management If the system and standards cannot meet the requirements of lean digital transformation, many effects may not be realized.” Lin Yisu said that in terms of talent strategy, Hengan Group has also simultaneously built long-term talents who understand production, management and improvement. effective mechanism.