|

1 |

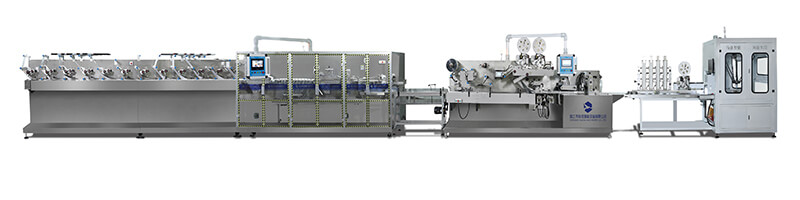

Material: Spunlace nonwoven fabric, calender bonded nonwoven fabric etc. |

|

|

2 |

Material Basic Weight: 35-80g/m² |

|

|

3 |

Jumbo Roll Spec.: Max W1200mm*Φ1200mm |

|

|

4 |

Jumbo Roll Axis: 4 axis of jumbo rolls, splicing without stopping the machine, core dia.: 3'' |

|

|

5 |

Wet Wipes Size: L140-205mm , W80-110mm |

|

|

6 |

Unfold Size: L140-250mm, W160-220mm |

|

|

7 |

Folding Type: |

1) Individual drawing & constant drawing |

|

2) Patented folding device, Z fold or small Z fold |

||

|

3) Choose one of the two types |

||

|

8 |

Production parameters: |

1) Stack quantity: 30-120 pieces ( height ≤ 90mm) |

|

2) Production Speed: 50-60 bags/min ( 80 pieces) |

||

|

3) Splicing joints detection and auto rejection |

||

|

9 |

Liquid Adding: |

1) 14 pcs of independent liquid adding pipes, can clean them individually |

|

2) 2.5-4 times liquid adding detection, set liquid adding weight by touch screen |

||

|

3) Real-time detection of liquid bucket level, set the alarm position of liquid by touch screen |

||

|

4) 2 sets of 650L hygienic grade stainless steel water tanks |

||

|

10 |

Control Method: |

1) Multi-axis controller, servo motor driven |

|

2) 10 inches touch screen, easier for operation |

||

|

3) Jumbo roll unwinding controlled by frequency converter |

||

|

4) Liquid adding motor controlled frequency converter, set liquid adding weight by touch screen |

||

|

5) Stacking controlled by independent servo, ensure neat stack and splicing joints rejection |

||

|

11 |

Machine Size: L9050 x W3600 x H2100mm |

|

|

12 |

Machine Power: AC380V (customizable), 50/60Hz, three phases five wires, 20KW |

|

|

13 |

Air Supply: 0.6-0.8Mpa, 130L/min |

|

|

14 |

Machine Weight: about 3000KG |

|

|

15 |

Optional devices: wet tissue paper specialized folding device, web guide controller, metal&weight detection and rejetion device |

|