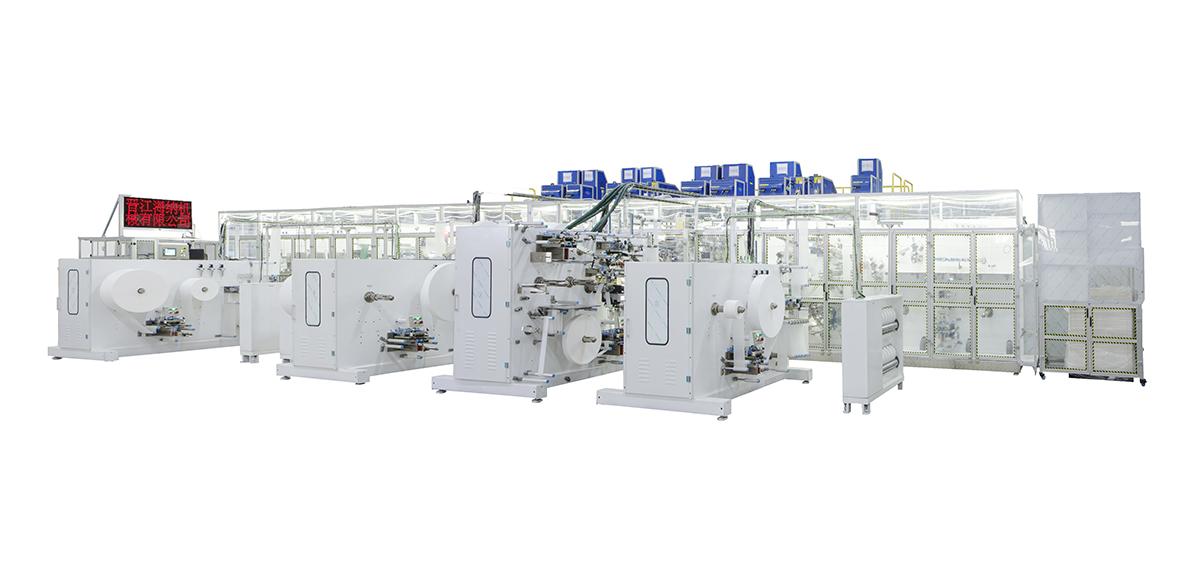

1. U-Shape Baby Pull-ups Diaper Machine Program System

Servo driven, intelligent HMI touch screen man-machine interface

2. Tension System

Tension control with buffer system, automatic web guiding system, to ensure materials stable working at zero speed splice.

3. Driven System

Servo drive, digital size change, ensure run synchronously at full process.

4. Safety System

Safety guard for operating side, emergency stop switch, security identifier, safety pull wire at driven side.

5. Auto Pack System

Auto stacker and Packaging machine to be defined by customer need.

6. Web Guiding System

BST ,Germany/FIFE, USA

7. Customized Function Available

|

Dimensions(L×W×H8) |

38m*10m*4m |

|

Design Speed: |

450ppm |

|

Stable Working Speed: |

400ppm |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

380KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

85 tons |

U-Shape Baby Pull-ups Diaper Machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | Waist inner NW |

| 11 | Waist outer NW |

| 12 | Elastic for waist |

| 13 | Construction glue |

| 14 | Elastic glue |

| 15 | Wetness indicator glue |

The U-Shape Baby Diaper Production Line incorporates advanced technology and engineering expertise to provide a comprehensive solution for diaper manufacturers....

Overall size: 38mx8mx5m (for reference only), Driven system: Servo drive, digital size change, ensure run synchronously at full process.Safety system: Safety guard for operating side, emergency s...

This machine adopts new generation ultrasonic welding technology of German Herrmann company Stable working speed :250 pcs/min With high efficiency and sta...

Baby Diaper Machine in Zambia The machine stable speed is 550pcs/min. The customer purchased this machine from Haina machinery in 2022. The company has ...

We've received positive feedback from parents who love the softness and snug fit of the diapers produced by this Baby Diaper machine. It's a win-win for everyone.Jack 2024-05-30

This Baby Diaper Machine has streamlined our manufacturing process and allowed us to deliver diapers that exceed our customers' expectations in terms of comfort and absorbencyMason 2024-05-30

We've seen a significant improvement in production output and product quality since we started using the Baby Diaper Machine. Our customers love the result!Liam 2024-05-30

With the Baby Diaper Machine, we've been able to expand our product line and meet the growing demand for baby diapers. Our customers are happy, and so are weLiam 2024-05-30