Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-06

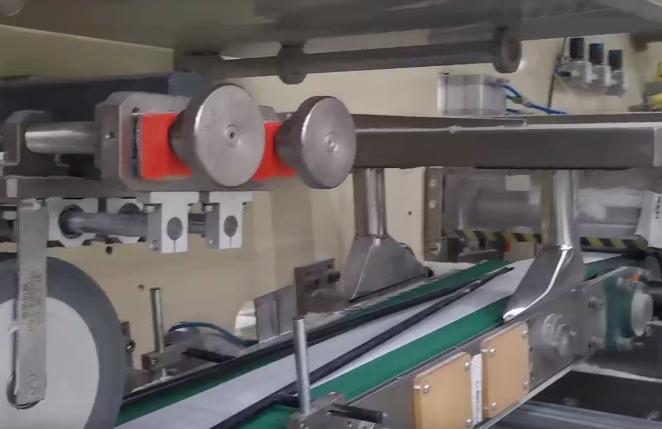

The continuous innovation of diapers equipment requires that the equipment installation technology must also be constantly improved and perfected to strengthen the understanding of the equipment and to fully grasp the structure, role and operation of the equipment.

Under the situation where production capacity and cost are the main measurement criteria, training pants enterprises put the focus of production and operation mainly on production and sales fields, and lack special attention to investment and guarantee work such as installation of machinery and equipment, which leads to the lack of attention to diapers equipment installation process. For example, in order to control production costs, enterprises will compress the purchase of new machinery and equipment as much as possible, and continue to use traditional machinery and equipment, resulting in an increase in the failure rate of machinery and equipment, which ultimately affects the progress and effectiveness of enterprise production. At the same time, enterprises lack the necessary learning and innovation in the introduction and installation of diapers machinery, too much to the current production situation as the standard for related decisions, which leads to the diapers equipment installation process to improve the lack of the necessary financial, technical and human resources to support the resources, some good machinery and equipment installation process research and use because of resource Some good research and use of machinery and equipment installation techniques are shelved because of insufficient resources.

Diapers equipment installation is a continuous activity, in addition to being responsible for the installation of machinery and equipment in place, but also to ensure that the operation of machinery and equipment in line with the expected goals and requirements. However, in the actual diapers machinery installation process, enterprises tend to install machinery and equipment in place, normal operation as a sign of the end of the installation activities, the collection of machinery and equipment after a period of operation, feedback and solve the problem is the lack of the necessary attention and implementation, which led to some newly installed machinery and equipment in operation after a period of frequent failures, affecting the normal production of enterprises. The normal production of the enterprise. At the same time, the lack of a clear division of responsibility in the installation of equipment, some production workshops in the discovery of equipment problems, do not know to whom to give feedback, and the lack of the necessary tracking mechanism to ensure the feedback of the problem, resulting in some feedback problems have been shelved for a long time, did not get a timely solution, and ultimately affect the overall effect of the installation of machinery and equipment to achieve. Moreover, in the current way of installing the main body with the supplier of machinery and equipment, enterprises are too passive in the maintenance and debugging of machinery and equipment installation, and can only wait for the supplier to arrange for the corresponding technical personnel to come to the door for maintenance, and enterprises lack the ability to take the initiative to solve problems.

Training pants manufacturing enterprises continue to improve and perfect the installation technology that keeps pace with the times and fully meets the characteristics of the equipment, so as to provide a strong basic guarantee for the normal operation of the equipment after installation.