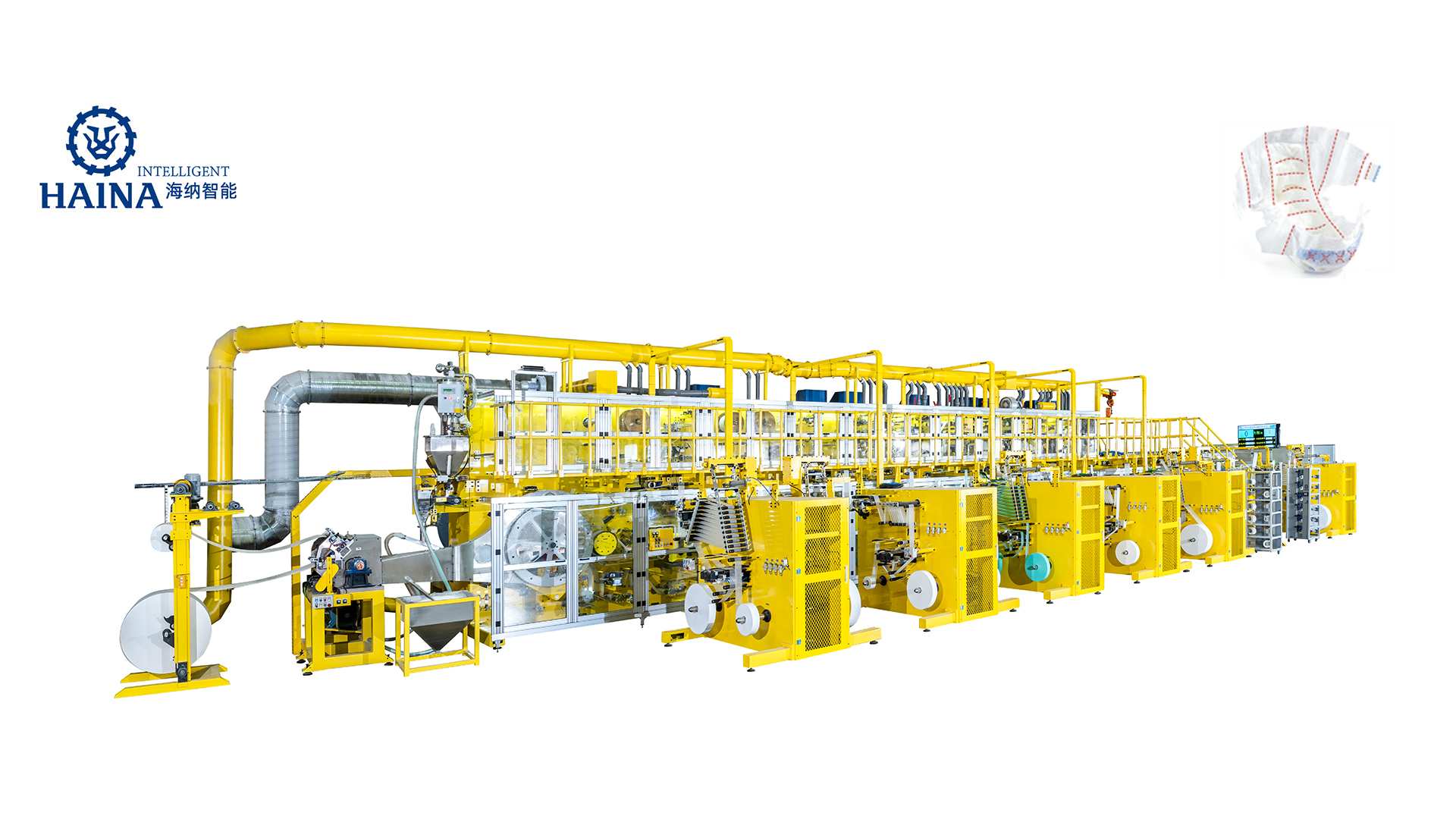

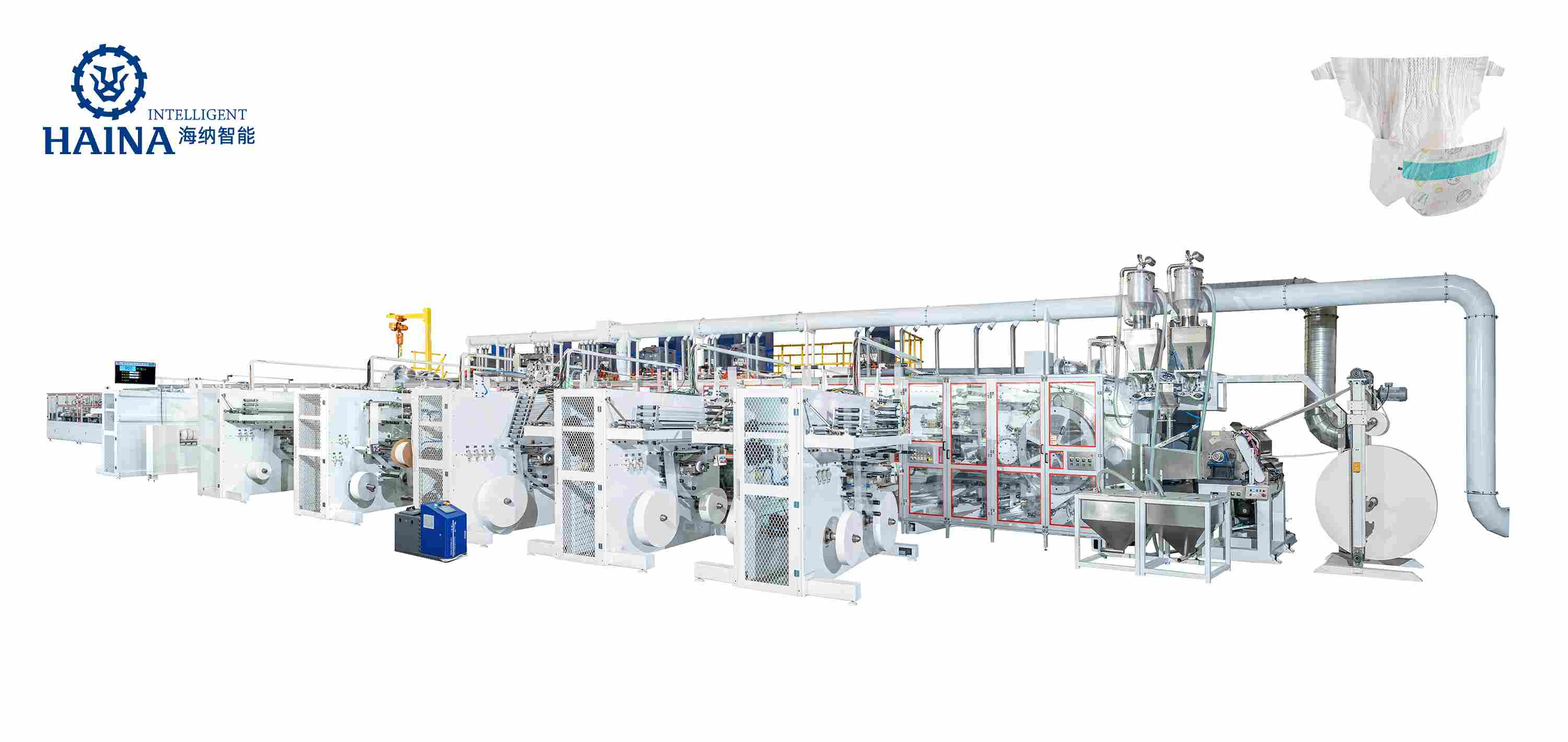

Recently, Fibertex Personal Care AG (Innowo Print) announced the addition of a new in-line printing unit for backside printing at its German printing facility, which has been fully integrated with the existing W&H flexographic production line. This technology enables the fully integrated online application of wetness indicators, surfactants, and various functional coatings on the same production line, achieving perfect register with surface patterns while ensuring compatibility with subsequent processing and manufacturing requirements. This initiative responds to growing market demand for Innowo Print's specialized solutions.

As infant care and adult incontinence products continue to evolve, brands demand higher standards for both design and performance. Traditional wetness indicator solutions have long suffered from multiple limitations: they primarily rely on offline processes, are often restricted to simple line patterns, cover only technical areas, and feature complex workflows with limited flexibility—all of which constrain design possibilities and production efficiency.

Innowo Print's new solution is transforming this landscape. With enhanced register control and wide-format printing capabilities, brands can now integrate functional elements like wet-marking directly into overall visual designs—no longer as an afterthought. Carsten Brøndum Pedersen, Global Printing Director at Fibertex, states: The breakthrough lies in perfectly aligning the functional back layer with the front-side pattern, enabling clients to achieve product expression that balances creativity with technical precision for the first time. Simultaneously, the system directly processes surfactants and functional coatings onto nonwovens, expanding product performance possibilities."

This technology also unlocks richer design possibilities: such as pattern-based functional zoning, icon-style wet-look systems, full-width graphic integration, and achieving front-to-back design alignment. Beyond wet-look effects, the system supports coating and functional printing on various nonwoven materials to optimize liquid management, create directional hydrophilic/hydrophobic zones, and enhance performance—all completed in a single printing pass.