Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-07

The best pad making machine maintenance personnel can quickly determine the part or cause of failure through the timely and effective application of fault diagnosis technology, and only timely maintenance of sanitary pad making machine can improve the normal operation of the equipment and maximize the economic benefits.

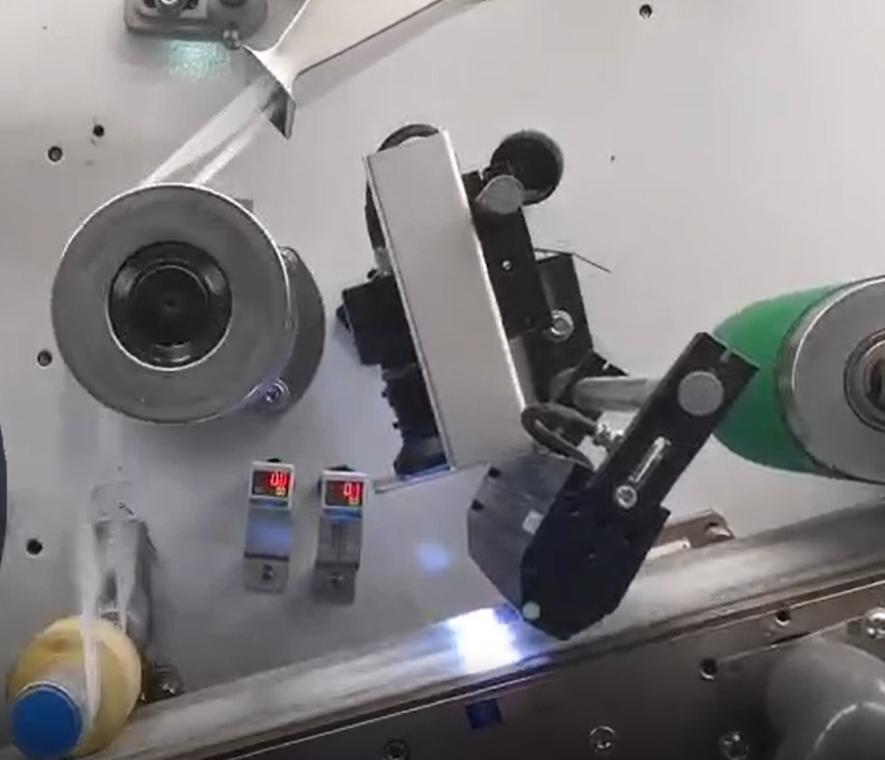

Firstly, as best pad making machine maintenance and overhaul personnel should be clear about the principle of equipment operation and correctly understand the relevant concepts before diagnosis; secondly, when diagnosing, we should firstly exclude the equipment safety limit triggered by human factors and downtime caused by multiple failures, and then analyze whether it is mechanical parts and related components failure or detection sensor's Finally, the internal components of the electronic control system should be confirmed according to the control principle of the equipment. The steps of diagnosis consist of excluding human error operation first, then confirming mechanical parts defects or damage, and finally excluding the internal problems of the electronic control system. And according to the diagnosis process to record the fault diagnosis and processing methods. For the subsequent maintenance of the equipment to do a good information reserve.

(1) Equipment oil wear needs to be accurately identified

This identification technology is more commonly used in diagnosis and detection is also very intuitive, the location where the oil wear occurs is mainly judged and determined by the impact of the oil on the operation of the best pad making machine, the physical state of the machinery and equipment itself and the specific composition of the oil.

(2) Classification detection fault technology

Non-destructive and destructive faults are the main classifications for machine and equipment operation and parts detection. But need the support of the preliminary equipment operation data, in the process of fault detection, through the specific fault classification helps the detection and maintenance personnel to quickly determine the cause and location of the fault, this move has a greater impact on the operation of machinery and equipment will be able to get priority treatment, so that unnecessary losses are reduced as much as possible.

(3) Technology for detecting equipment parameters

Fixed parameters are the characteristics of each machine and equipment, inherent parameters will accompany each component. For example, the vibration frequency and related data occurring in the operation of machinery and equipment is the basis for judging the degree of damage to mechanical transmission parts;, this technology is a particularly worthy of application and promotion due to its easy operability and high accuracy rate.

(4) Online and offline diagnosis technology

Equipment failure was often diagnosed offline in the past. With the application and development of information technology, online diagnosis is now more practical and reliable in terms of the timeliness of fault detection, and has an increasing proportion in the electrical control system of machines and equipment, and basically belongs to the full-coverage application for large and medium-sized automation control equipment in factories. Model analysis method, signal processing method, etc. are specific methods of online technology for diagnosing faults.

In the rapid development and application of artificial intelligence and information technology, electronic information inspection technology is gradually replacing the empirical detection technology, for the best pad making machine technology level forward and the development of society has laid a good foundation.