Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-12

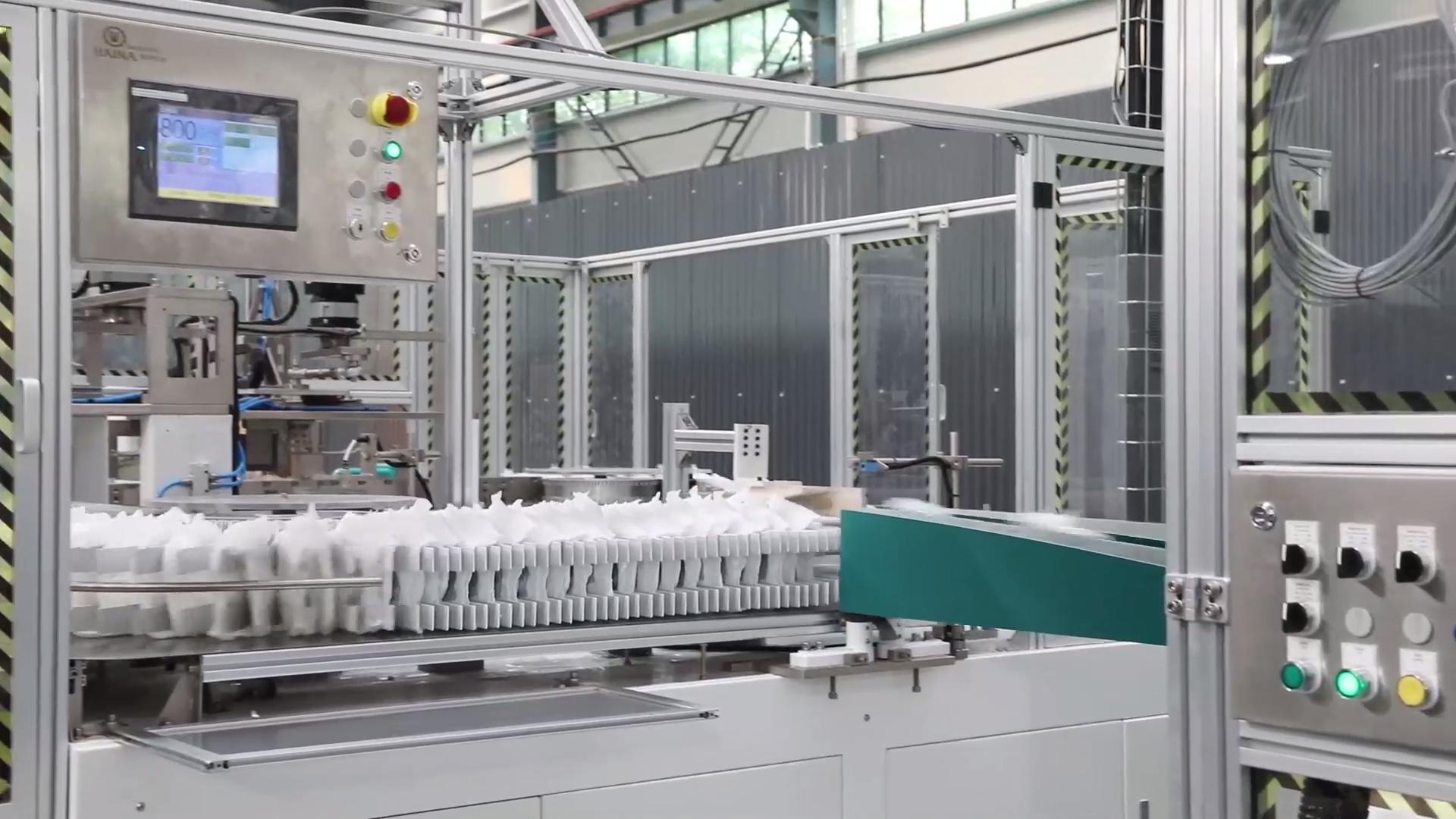

Baby diaper production line manufacturers Maintenance is the daily work that operators and maintenance personnel must perform in order to maintain the normal technical state of the equipment and its service life, and it is also one of the responsibilities of operators and maintenance personnel. Baby diaper production machine When the maintenance work is done, it can reduce maintenance costs, reduce product costs, ensure product quality and improve production efficiency.

Operators should strictly abide by the operating procedures and the daily maintenance and maintenance system of the equipment, operate the equipment correctly and reasonably in strict accordance with the requirements of the equipment and system manuals, and try to avoid the use of the equipment due to improper operation. baby diaper production line manufacturers is an advanced processing equipment with high degree of automation, high processing precision and complex structure. To give full play to the high efficiency of baby diaper production line manufacturers, it is necessary to operate correctly and maintain carefully to ensure the utilization rate of the equipment. Correct operation and use can prevent abnormal wear and tear of equipment and avoid sudden failures. Doing a good job in daily maintenance can keep the equipment in a good technical state, prolong its service life, discover and eliminate hidden troubles in time, so as to ensure safe operation and smooth production.

baby diaper production line manufacturers After running for a certain period of time, some electrical components or mechanical parts will inevitably have some damage or failure. How to extend the service life of electrical components and the wear cycle of parts and components, and prevent various failures, we will eliminate malignant accidents in the bud In order to improve the normal working time and service life of the equipment, it is important to do preventive maintenance. There are some abnormal phenomena in the operation of the equipment, but it does not necessarily affect the operation. When the production task is busy, the equipment is often used to work with illnesses, and preventive maintenance work is not performed in time. In the current equipment management concept, it should be maintained beforehand rather than repaired afterwards. Maximize equipment benefits and save costs.

baby diaper production line manufacturers The key to preventive maintenance is to strengthen daily maintenance. The main maintenance work includes the following:

(1) Daily inspection

Including hydraulic system, spindle lubrication system, rail lubrication system, cooling system, air pressure system. According to the normal conditions of each system in the production process, it is tested. For example, when the process inspection of the spindle lubrication system is carried out, the power light should be on, and the oil pressure pump should be running normally. If the power light is not on, the spindle should be kept stopped and contact the mechanical engineer. make repairs.

(2) Weekly inspection

Including equipment parts and spindle lubrication system, they should be checked correctly every week, especially for equipment parts, iron filings should be removed, and external debris should be cleaned to ensure that the equipment is clean.

(3) Monthly inspection

Check power supply and air desiccant. The power supply voltage is rated at 220V-380V under normal conditions, and the frequency is 50Hz. If there is any abnormality, it should be measured and adjusted. The air desiccant should be removed once a month, and then cleaned and dried.

(4) Quarterly inspection

The quarterly inspection should mainly be inspected from the three aspects of the equipment bed, hydraulic system and spindle lubrication system. For example, when checking the equipment bed, it mainly depends on whether the equipment accuracy and equipment level meet the requirements in the work manual. If there is any problem, please contact the maintenance personnel immediately. When checking the hydraulic system and spindle lubrication system, if there is any problem, replace the new oil and clean it.

In a word, carrying out regular inspection is an effective method for baby diaper production line manufacturers maintenance. Equipment maintenance based on regular inspection is a regular inspection management system developed by Japan on the basis of the preventive maintenance system introduced from the United States. Regular inspection is to carry out fixed-point and regular inspection and maintenance of equipment according to the provisions of the established maintenance documents. This modern maintenance management system with regular inspection as the core during the operation of the equipment can achieve the purpose of reducing the failure rate and maintenance cost and improving the maintenance efficiency.