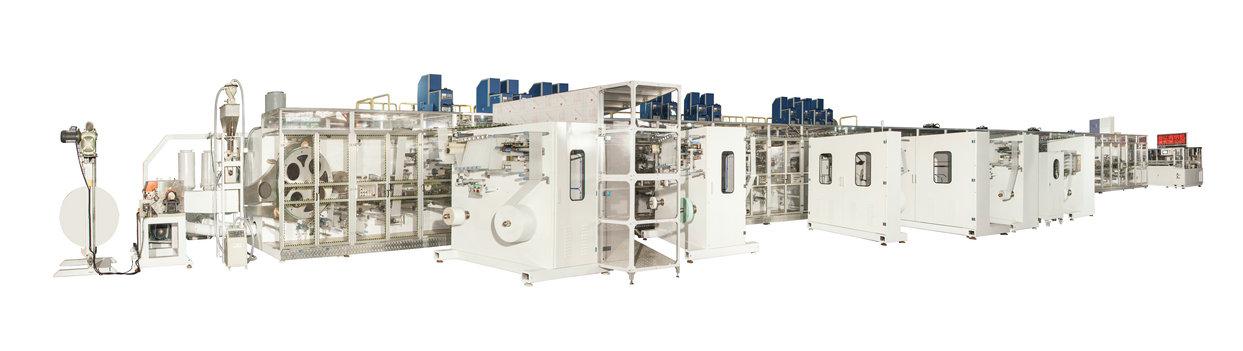

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-10

The loss of working ability of the machine is called failure, and the loss of the specified working ability of machine parts is called failure. The failure of period diaper machine and the failure of parts are inseparable. Parts deformation, fracture, corrosion and other failures caused by normal wear or physical and chemical changes of parts are also called natural failures. period diaper equipment. The repair method of faulty parts and the precautions for disassembling the equipment during repair are also highly valued!

Repair method for restoring both the nature of the fit and the shape and size of the part

(1) Welding repair method

Metal welding is to firmly combine separate metal weldments into a whole through diffusion and connection between atoms. Depending on the welding equipment, welding includes gas welding and electric welding. Many broken and worn parts are mostly repaired by repair welding and surfacing. Some components are vehicle and ground after welding to restore their original geometry and size.

(2) Re-casting method

After the babbitt alloy of the sliding bearing is worn to the limit, the residual alloy is melted away, and the process of re-casting the new babbitt alloy is called the replacement casting method. In this way, the performance standard of the old plain bearing can be completely restored.

(3) Electroplating (brush plating, electrocoating) method

Electroplating is a process in which an electrochemical reaction occurs when a direct current is passed through an electrolyte to realize the deposition of metal on the surface of the plated part.

(4) Spraying and spray welding

Spraying is to spray the molten material particles on the surface of the prepared rough parts with a high-speed air flow to form a relatively firm mechanical bonding layer.

The spray welding process is developed on the basis of the spraying process. It re-melts the sprayed layer to obtain a coating with similar surfacing properties on the surface of the part.

(5) Bonding and bonding method

Bonding is a repair process that uses the combined chemical, physical and mechanical forces between the adhesive and the parts to bond the parts or the cracks, holes, wear and other defects of the bonded parts.

(1) Preparations before disassembly

a. The workplace should be spacious, bright, flat and clean.

b. The dismantling tools are prepared and the specifications are appropriate.

c. Prepare benches, separate basins, oil drums, etc. for placing parts according to different purposes

(2) Basic principles of mechanical disassembly

a. According to the model and related information, the structural characteristics and assembly relationship can be clearly understood, and then the methods and steps of disassembly and disassembly can be determined.

b. Correctly select tools and equipment. When the decomposition encounters difficulties, first find out the reasons and take appropriate methods to solve them. It is not allowed to smash and knock violently to prevent damage to parts and tools. .

c. When disassembling parts or assemblies with specified directions and marks, the directions and marks should be clearly marked, and if the marks are lost, they should be marked again.

d. In order to avoid damage or loss of the dismantled parts, they should be stored separately according to the size and accuracy of the parts, placed in the order of disassembly, and the important precision parts should be specially stored for safekeeping.

e. The removed bolts, nuts, etc. should be put back in place without affecting the repair, so as to avoid loss and facilitate assembly.

f. Disassemble as needed, and it can be judged that the condition is good without disassembly. On the one hand, it can save time and labor, and on the other hand, it can avoid damage during disassembly and assembly and reduce the accuracy of parts assembly. However, the parts that need to be disassembled must be disassembled. It is not easy to save trouble and sloppy, so that the repair quality cannot be guaranteed.

After the repair of period diaper machine, the overall inspection is required, which is a comprehensive quality appraisal after the repair, and is also an important link to ensure that the mechanical equipment has good performance, safety and reliability after delivery.