Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-13

The traditional maintenance methods and maintenance experience based on mechanical equipment, as well as the "bathtub curve" failure characteristics that have been widely known by maintenance personnel, are completely unsuitable for this type of equipment. The future smart factory will be the trend of diaper machinery. Therefore, understanding the fault characteristics of such equipment and summarizing maintenance methods are important issues in the construction of smart factories.

Smart devices are powerful and easy to operate, but traditional smart device maintenance methods and maintenance experience are far from enough. This article helps you analyze the fault characteristics of Smart diaper equipment and point out the strategic direction of maintenance.

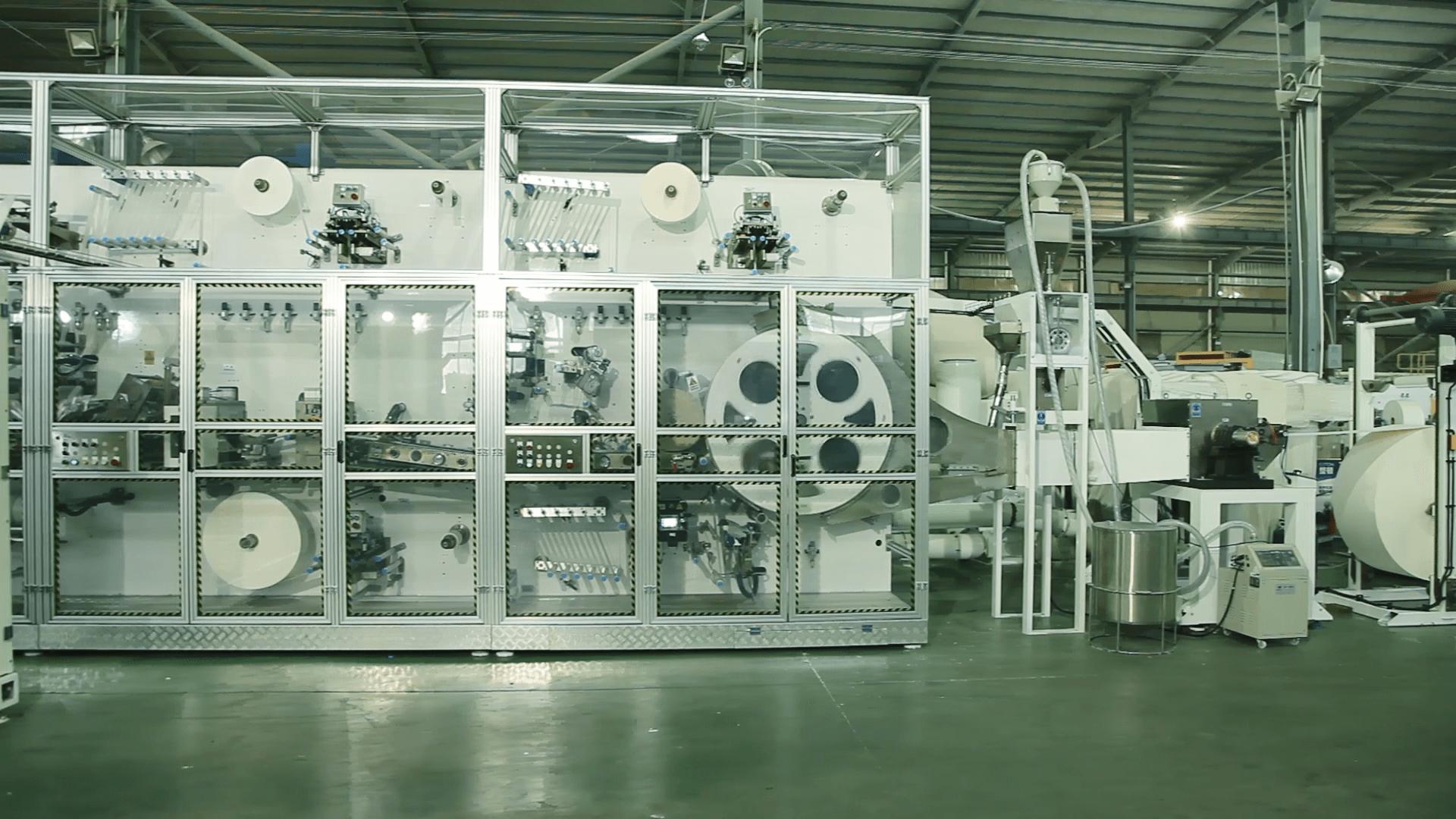

Intelligent equipment refers to manufacturing equipment with functions of perception, analysis, reasoning, decision-making and control. It is the integration and deep integration of advanced manufacturing technology, information technology and intelligent technology. The characteristics of intelligent equipment failure are as follows:

(1) Traditional mechanical failures still exist, but will be greatly reduced. Although the intelligent equipment is equipped with an advanced microprocessing center, the final machining process still requires mechanical methods consistent with traditional machining modes, such as cutting, thermal machining, etc.

(2) Maintenance of the new intelligent system, including system backup, virus detection and other operations. Generally there are: First, after the new machine is powered on for the first time. The second is before any modification is made and the modification is completed. The third is regular backup and recovery of equipment, such as once a week. The fourth is to control the maintenance of the computer.

(3) Different from the traditional maintenance method, the faults of smart devices are mostly electrical faults, and their maintenance has clear requirements for the maintenance environment, such as dustproof, anti-static, etc. This also determines the relatively high complexity of maintenance.

(4) Unlike traditional mechanical equipment, more intelligent equipment presents invisible faults. For example, the coordinates of the robot are out of order, or it is running in low speed mode. These faults are mostly caused by the mismatch of the parameters of the control system or the production system, such as overloading and other factors.

(5) Burst is also a fault characteristic of intelligent equipment. The traditional model classes show different gradients, and the sudden failure of smart devices increases. This is mainly caused by software system failure or BUG, or electrical interference factors.

(6) According to statistics, electrical faults of intelligent equipment account for 79-80% of the total faults. The elimination of such faults requires extremely high professionalism.

(7) Due to the development of intelligent equipment and the low level of standardization of parts and components, special maintenance techniques are required for different brands, which poses a challenge to the cultivation of enterprise maintenance resources.

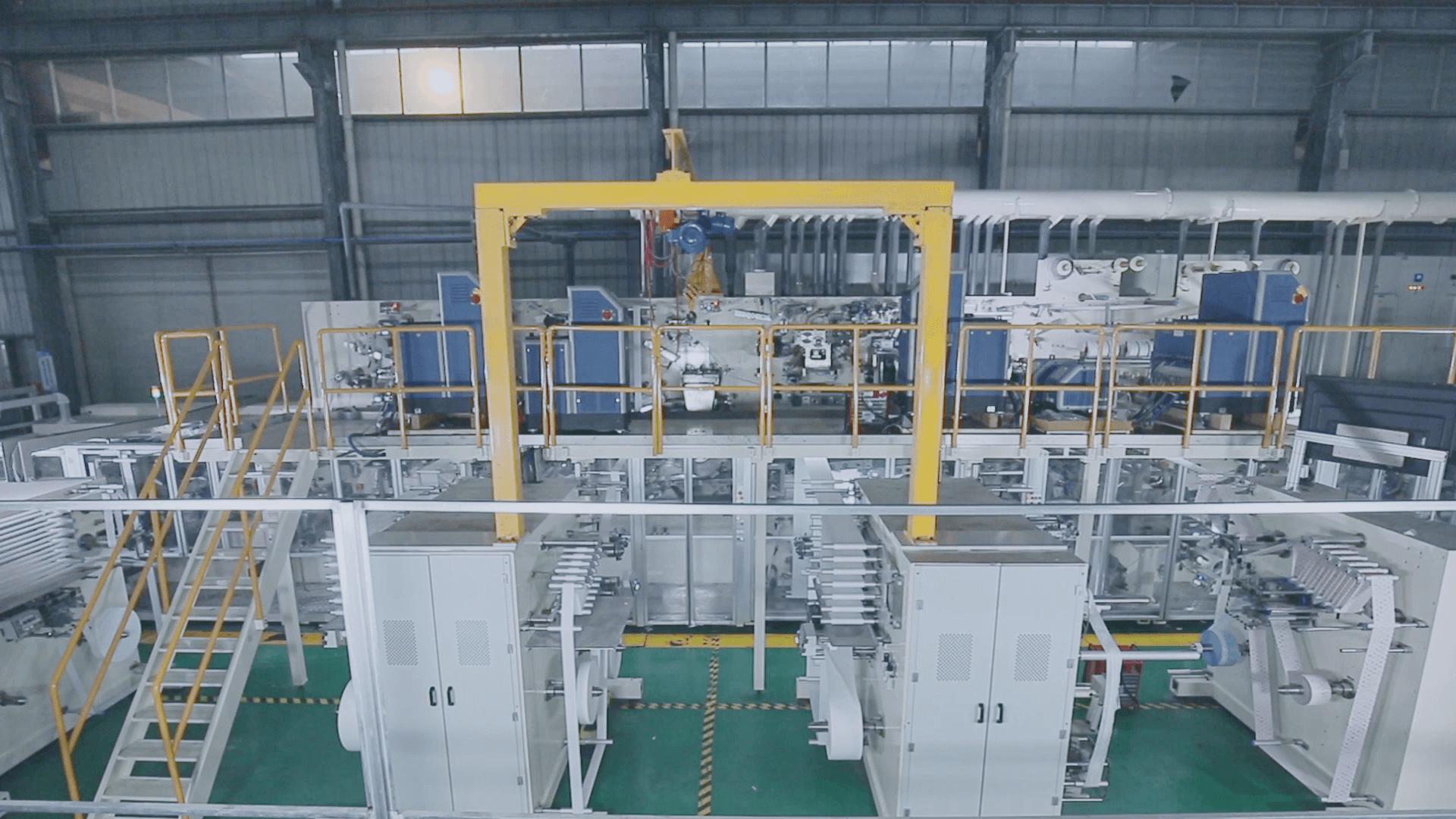

Under the new manufacturing environment, equipment management will face unprecedented challenges, and traditional technical methods and organizational management will be difficult to effectively guarantee the operation of diaper equipment, requiring innovation or redesign. We emphasize a few points:

(1) Strategically attach importance to the new development of equipment technology. Smart factories need to place maintenance departments in an important position to ensure production, rather than logistics support and auxiliary departments.

(2) The traditional means of "looking, smelling, and touching" are no longer effective, and knowledge-based talents who master specialized diagnostic techniques need to be cultivated.

(3) Pay more attention to the concept of 5S and TPM. As mentioned above, intelligent equipment has higher requirements on the operating environment, and the maintenance and daily protection of equipment have a greater impact on the health level of equipment.

(4) It is no longer a wrench + cone, but a manual + computer. Tools such as dedicated diagnostic tools, electronic maintenance, interactive electronic graphics will be standard for maintenance personnel.

The "Made in China 2025" and "Internet +" actions focus on deploying intelligent manufacturing and propose vigorously developing intelligent manufacturing. And the proposed 6 intelligences, of which equipment intelligence is the foundation and the key point. And intelligence will be the main trend of diaper machinery, and correct maintenance can make it develop better!