1. Feminine Sanitary Napkin Machine Program System

Servo driven, intelligent HMI touch screen man-machine interface

2. Tension System

Tension control with buffer system, automatic web guiding system, to ensure materials stable working at zero speed splice.

3. Driven System

Servo drive, digital size change, ensure run synchronously at full process.

4. Safety System

Safety guard for operating side, emergency stop switch, security identifier, safety pull wire at driven side.

5. Auto Pack System

Auto stacker and Packaging machine to be defined by customer need.

6. Web Guiding System

BST ,Germany/FIFE, USA

7.Feminine Napkin Machine+Auto Bagger Customized Function Available

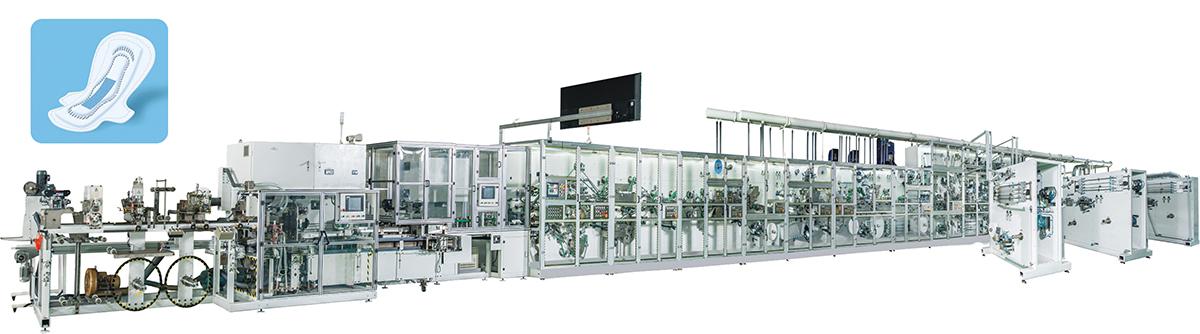

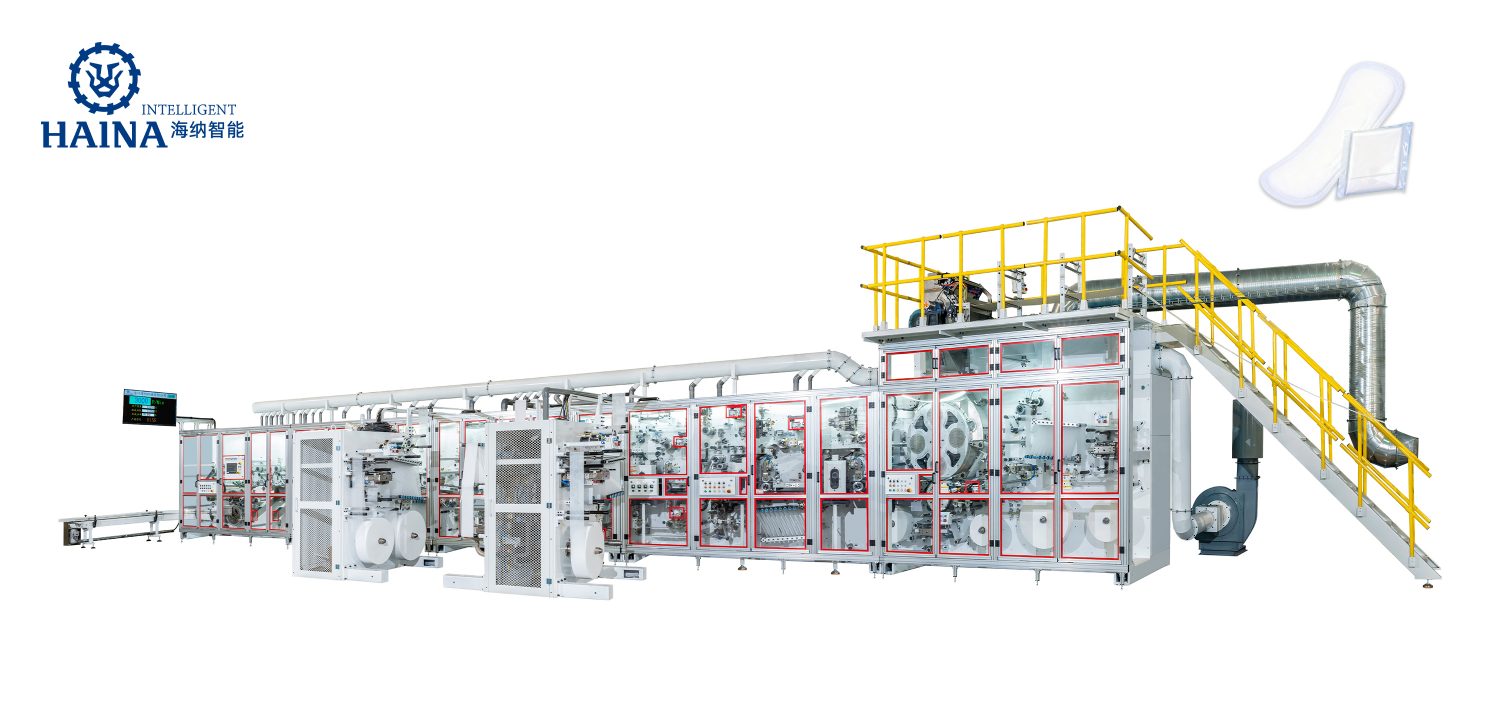

Feminine Sanitary Napkins Machine Product Description:

The Feminine Sanitary Napkins Machine is a state-of-the-art piece of equipment designed for the efficient and automated production of feminine sanitary napkins. It incorporates advanced technology and precision engineering to ensure high-quality output while minimizing downtime and waste.This machine is an essential tool for manufacturers in the personal hygiene industry, providing them with a reliable and cost-effective solution.

Feminine Sanitary Napkins Machine Technical Features:

1. High Speed: The Feminine Sanitary Napkins Machine is capable of operating at high speeds, ensuring maximum productivity and output.

2. Versatility: This machine supports various sizes and shapes of sanitary napkins, offering flexibility in production to meet different market demands.

3. Automated Operation: With its advanced automation system, this machine significantly reduces the need for manual intervention, thereby increasing efficiency and reducing labor costs.

4. Quality Control: The machine is equipped with advanced sensors and monitoring systems to ensure consistent product quality throughout the production process.

5. Easy Maintenance: The design of this machine facilitates easy maintenance and quick troubleshooting, minimizing downtime and maximizing uptime.

Product Applications:

The Feminine Sanitary Napkins Machine is specifically designed for manufacturers in the feminine hygiene industry. It can produce a wide range of feminine sanitary napkins, including regular, ultra-thin, overnight, and panty liner variants. This machine helps meet the growing demand for feminine hygiene products, ensuring that manufacturers can supply high-quality and affordable products to meet their customers' needs.

Feminine Sanitary Napkins Machine Key Functions:

1. Raw Material Feeding: The machine accurately feeds the required raw materials, such as cotton pulp, non-woven fabric, and absorbent polymer, ensuring consistent product quality.

2. Core Formation: It forms the core of the sanitary napkin by layering and compressing the materials, ensuring proper absorption and leak protection.

3. Backsheet Attachment: The machine attaches the backsheet material to the core, providing a leak-proof barrier and enhancing comfort.

4. Ultrasonic Sealing: It employs ultrasonic technology to seal the edges of the sanitary napkin, ensuring durability and preventing leakage.

5. Product Shaping and Cutting: The machine shapes the sanitary napkin into its final form and cuts it into individual units, ready for packaging and distribution.

Feminine Sanitary Napkins Machine Precautions:

1. Proper Training: Operators should receive thorough training on machine operation, maintenance, and safety protocols to ensure optimal performance and minimize the risk of accidents.

2. Regular Maintenance: Routine maintenance should be performed as per the manufacturer's guidelines to keep the machine in top condition and prevent unexpected breakdowns.

3. Safety Measures: Operators must adhere to all safety procedures, including wearing appropriate protective gear and ensuring a safe working environment.

4. Quality Control: Regular inspections and quality checks should be carried out to ensure that the machine is producing sanitary napkins that meet the required standards.

5. Compliance with Regulations: Manufacturers should ensure that the Feminine Sanitary Napkins Machine complies with all relevant industry regulations and standards to maintain product safety and consumer trust.

In conclusion, the Feminine Sanitary Napkins Machine offers advanced technology, high efficiency, and reliable performance for the production of feminine sanitary napkins. Its versatility, automated operation, and quality control features make it an indispensable tool for manufacturers in the personal hygiene industry. By following the necessary precautions, operators can maximize themachine's potential and produce high-quality sanitary napkins efficiently.

Feminine Sanitary Napkin Machine

|

Dimensions(L×W×H8) |

30m*6m*3m |

|

Design Speed: |

1000ppm |

|

Stable Working Speed: |

800-900ppm |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

220KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

55 tons |

Daily maintenance of Feminine Sanitary Napkin Machine

1. For the daily maintenance of Sanitary Napkin Machine, it is mainly daily maintenance and weekend cleaning. Among them, the daily maintenance should be strictly done before the operation, and the equipment should be checked first and then started.

2. The contents of Sanitary Napkins Machine inspection mainly include: lubrication system, traditional system, and control system. At the same time, problems should be identified and dealt with in a timely manner. After completing the work of the day, the equipment should be carefully cleaned and maintained according to the 4S management standard, so that the maintenance work can reach the regular and institutionalized standard.

Feminine Sanitary Napkin Machine

| No. | Raw materials |

| 1 | Topsheet(NW or PPF) |

| 2 | Fluff pulp |

| 3 | SAP |

| 4 | ADL N.W. |

| 5 | Tissue |

| 6 | Backsheet |

| 7 | Back release paper |

| 8 | Wings release paper |

| 9 | Pouch film |

| 10 | Easy tape |

| 11 | Air laid paper |

| 12 | SAP Paper |

| 13 | Hydrophobic N.W. |

| 14 | Construction glue |

| 15 | Position glue |

Overall size: 30mx6mx3m(for reference only), Program system: Servo driven, intelligent HMl touch screen man-machine interface.Product structure: Flat(or te...

The Feminine Sanitary Napkins Machine is a state-of-the-art piece of equipment designed for the efficient and automated production of feminine sanitary nap...

1.Product Structure: Flat(or textile edge)Topsheet,ADL(blue core), Tissue (or airlaid), Cotton core(mix with SAP), Back sheet, Release paper,Pouch film, Fa...

Our customers have noticed the difference in the quality of our feminine napkins since we started using this machine. Highly recommendedMegan H 2024-05-31

The Feminine Napkin Machine is a game-changer for our business. It's efficient, reliable, and produces high-quality products consistentlyRachel W 2024-05-31

The Feminine Napkin Machine has helped us streamline our manufacturing process and reduce costs. It's a fantastic investment for any companySamantha P 2024-05-31

Feminine Napkin Machine has saved us so much time and effort in producing feminine napkins. Couldn't be happier with our purchaseJennifer R 2024-05-31