1. Meeting the Needs of Different Age Groups. 2. Enabling Customization and Specialization. 3. Improving Sustainability and Environmental Impact....

Introduction. 1. Understanding the Diaper Production Process. 2. Key Features and Functions of Lady Diaper Machines. 3. Quality Assurance and Maintenance. Concl...

1. Automated Production Process. 2. Optimal Resource Utilization. 3. Flexibility and Customization....

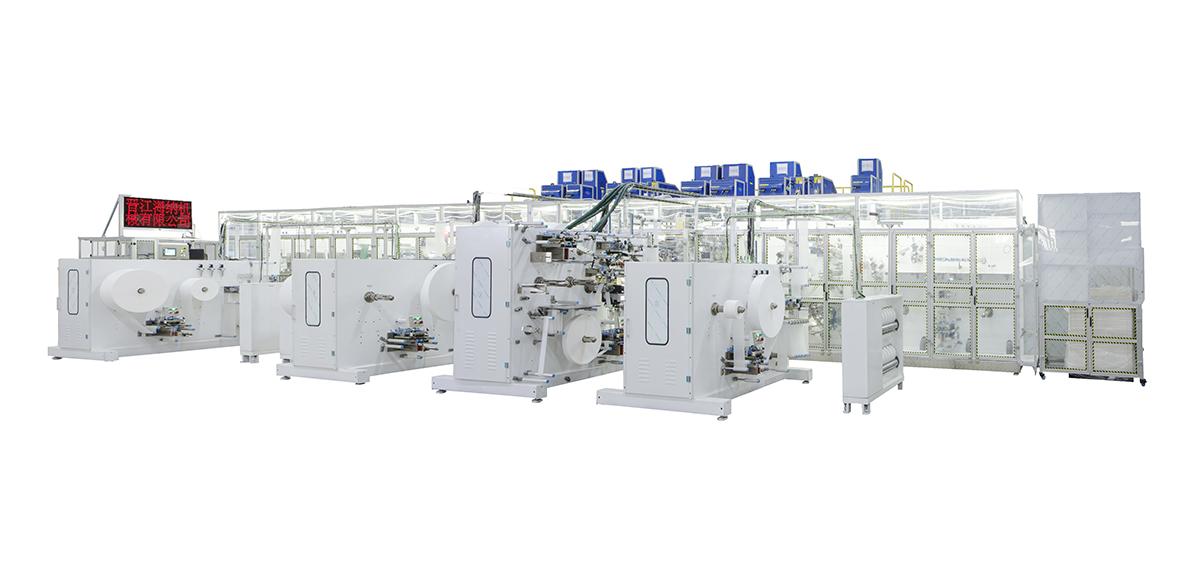

The use of lady diaper machine has greatly improved the production level of the industry, which has largely improved the production efficiency and reduced the l...

lady diaper machineInitial use managementrefers to the initial use management after equipment is installed and put intouse, including equipment debugging, use, ...

With the continuous progress of science and technology and the rapid development of modern production, the role of machinery and equipment as an important facto...

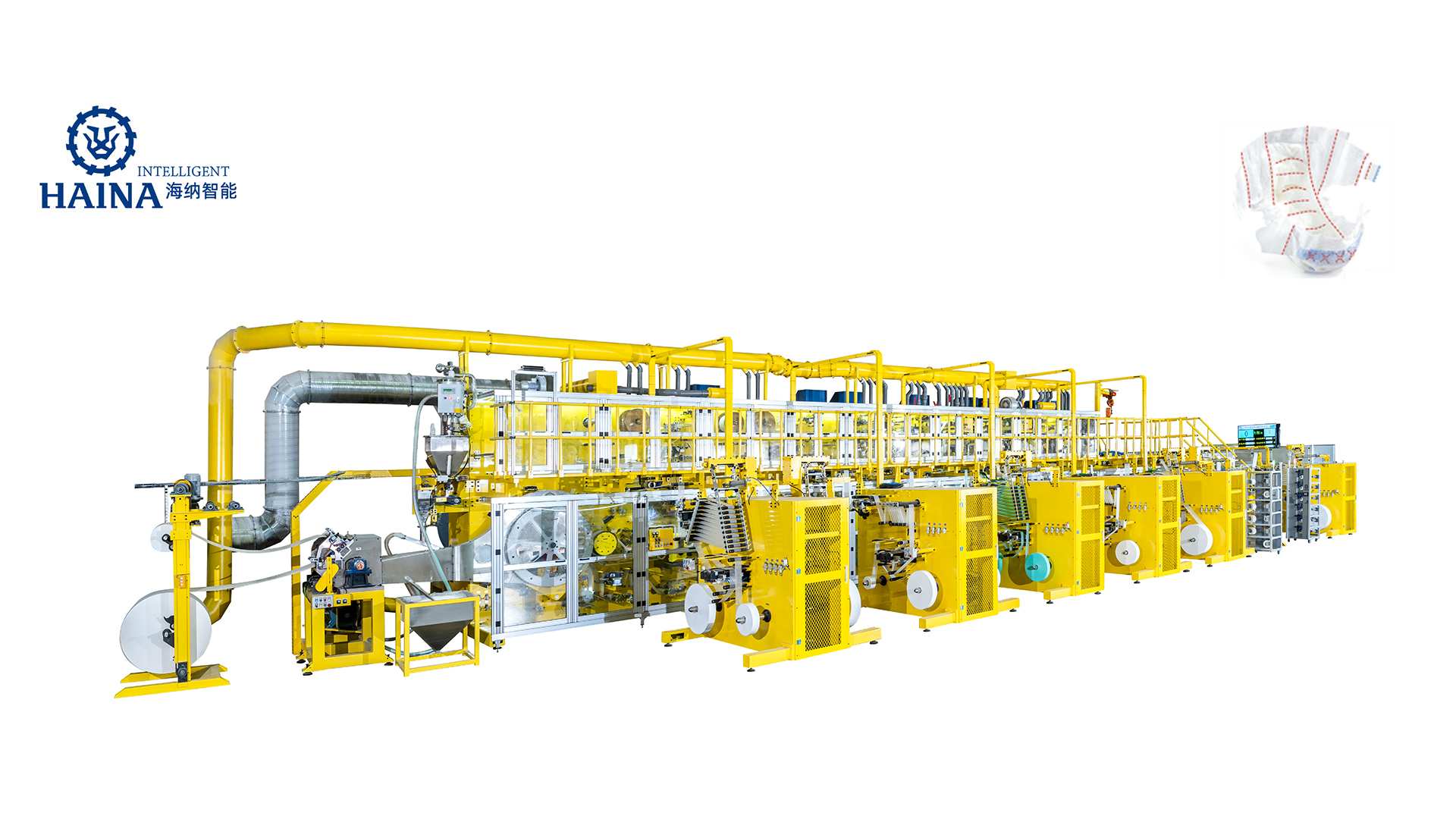

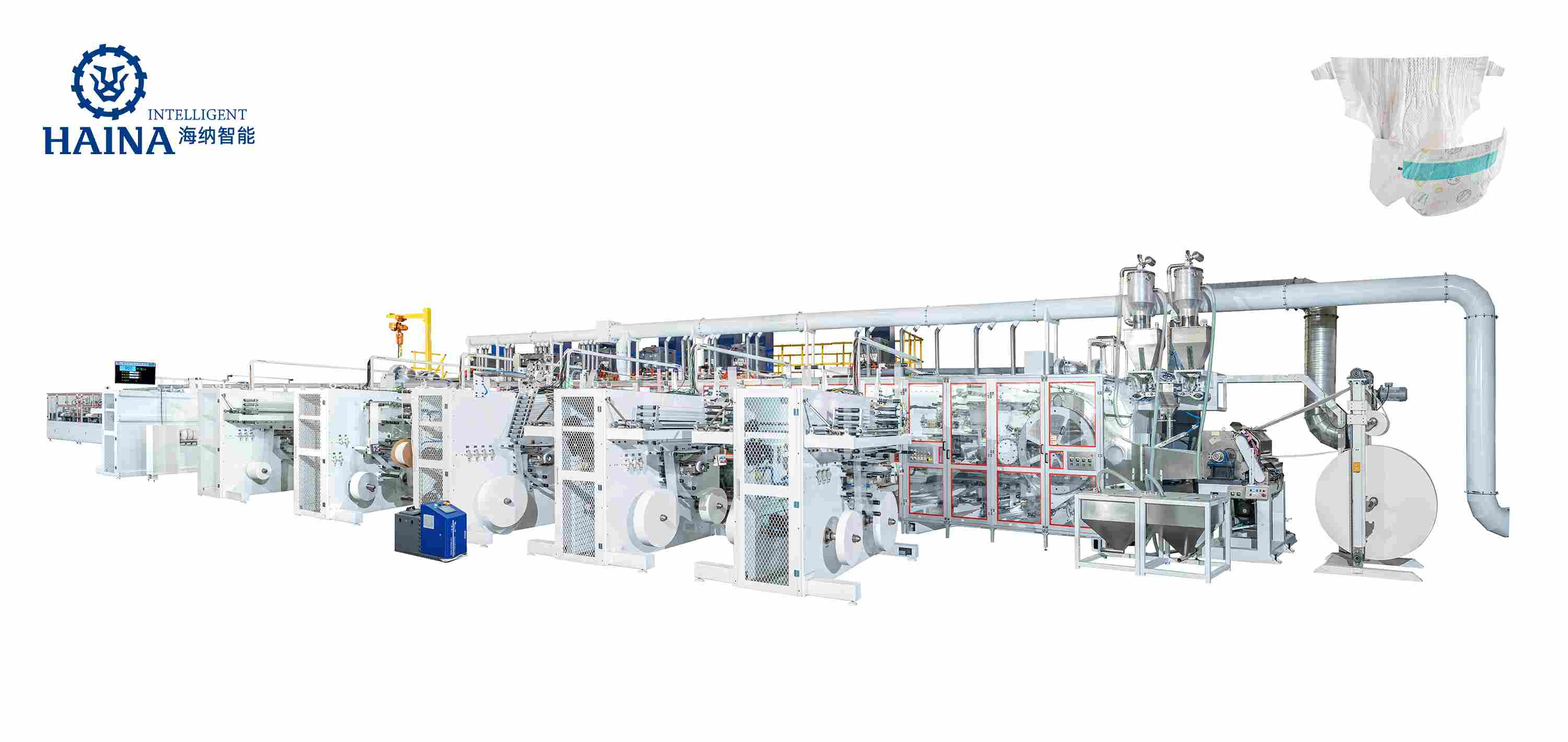

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully au...

1.Product structure: Upper lower tissue (or airlaid ), Cotton core (mix with SAP), ADL,PE flm, Frontal tape, Topsheet hydrophilic nonwoven, Leg cuff hydrophobic nonwoven, "S" cut side...

Overall size: 38mx8mx5m (for reference only), Driven system: Servo drive, digital size change, ensure run synchronously at full process.Safety system: Safety guard for operating side, e...

This isDiaper Making Machine in Hungary, this machine is to produce baby diaper from new born size, machine stagble working speed is 450pcs/min. This machine also included the Nordson g...

This is Disposable Bed Pads Machine in Czech Republic. The machine stable speed is 250meter/min.The Disposable Bed Pads is a disposable hygiene product, which made up of nonwoven, ti...