Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-07-18

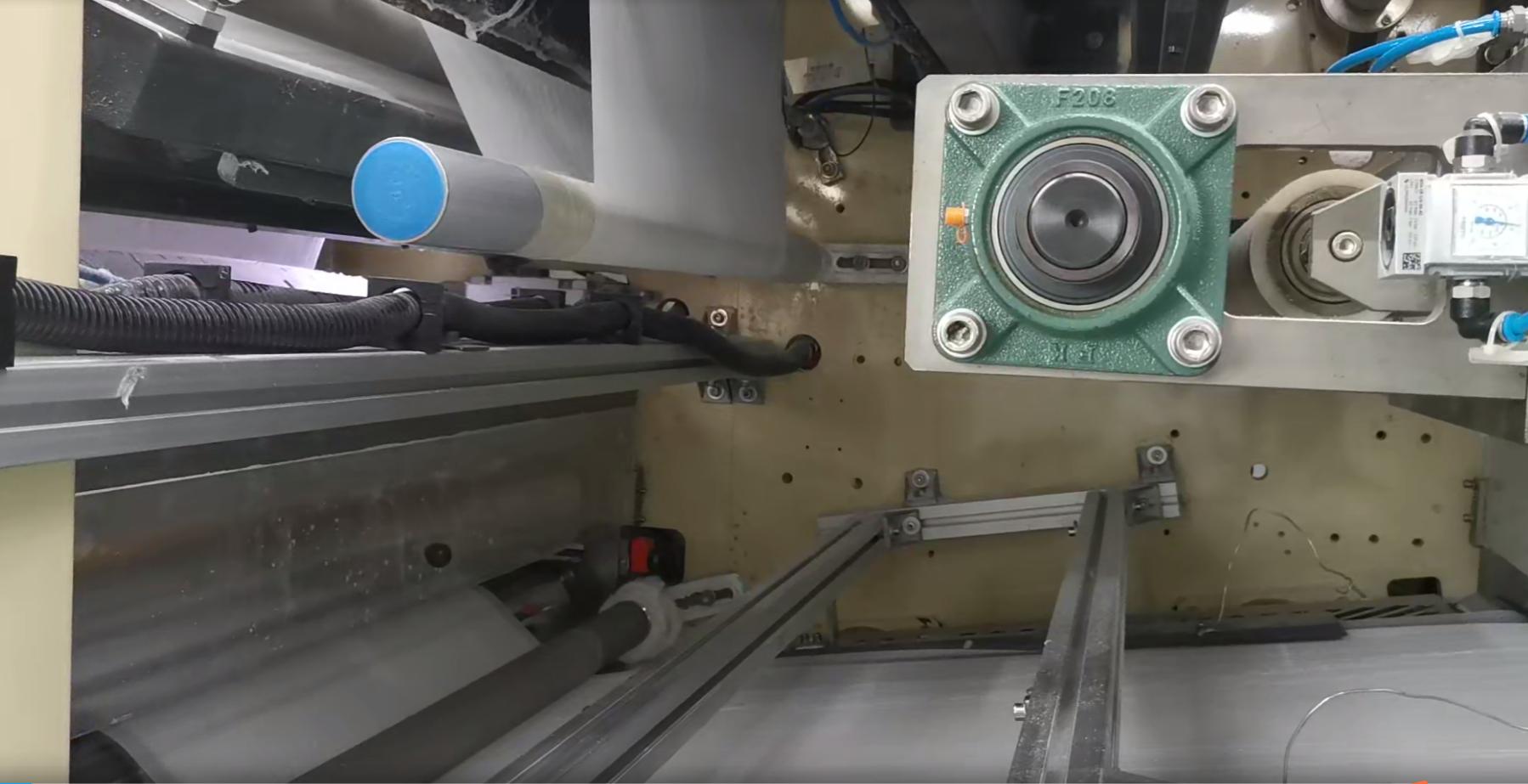

The use of lady diaper machine has greatly improved the production level of the industry, which has largely improved the production efficiency and reduced the labor input. However, the machine also has its own disadvantages. The complexity of the machine and the equipment determines that the person using it must have a certain amount of appropriate knowledge. When using it, care must be taken and careful maintenance of the female diaper machine must be observed.

Lady diaper machine common faults according to different classification methods can be divided into the following five types.

The first type: according to the part where the failure occurs can be divided into hardware system failure and software system failure. Software system failure is mainly caused by errors in the logic control program, incorrect parameter settings, and errors in the processing program of the parts.

The second type: according to the fault when there is no indication can be divided into no diagnostic indication fault and diagnostic indication fault. As the name suggests, a fault with diagnostic indication is a fault in which the diagnostic system monitors the entire machining process while the machine is running, and when a problem occurs in a certain step, it will immediately alarm or display in the form of text. Failure without diagnostic indication means that there is no indication when the failure occurs. These failures are mainly caused by years of mechanical use, mechanical parts wear and tear, resulting in the program and mechanical matching problems.

The third type: is divided according to the contingency of failure. If when the machinery meets a certain condition, a certain failure will occur, then, this failure is a systematic failure. And a random fault is a fault that may occur when a certain condition is satisfied. Random failure is more difficult to solve because of its uncertainty.

The fourth type: is divided according to whether the fault appears destructive or not. The destructive ones are called destructive faults and the non-destructive ones are called non-destructive faults. The last one is called machine characteristic degradation failure, when this kind of failure occurs, although the machine can operate normally, but can not produce qualified products.

To sum up, in diagnosing the common mechanical faults in the use of lady diaper machine, there should be both "practical diagnosis method" in the traditional sense and "modern diagnosis method" combined with advanced testing methods. Among them, practical diagnosis technology is also called mechanical testing method, refers to the machine and equipment maintenance personnel with conventional inspection tools and with the sense organs on the machine to ask, see, touch, hear, smell and a series of diagnostic methods. It can quickly determine the fault parts of the machinery and monitor the deterioration trend, the mechanical fault with difficult problems, a sophisticated diagnosis. Modern diagnosis method means that, according to the practical diagnosis method to select the difficult problems, and handed over to professionals using advanced testing means, to carry out accurate quantitative testing and analysis, and according to the location of the fault, data and causes, to determine what solutions should be taken.

When dealing with the problem, generally use practical diagnosis method to diagnose the real state of the machine, only in the practical diagnosis of difficult problems, will go to the use of modern diagnosis method, the next step in the diagnosis of the machine, and a combination of the two diagnostic techniques, in order to obtain a reasonable solution to mechanical problems.

Because lady diaper machine repair is also a highly technical work. Therefore, the technical requirements of maintenance personnel will also be improved, machine and equipment maintenance personnel need to master not only the knowledge of electrical systems, but also the knowledge of hydraulic and mechanical aspects. Therefore, to improve the ability of maintenance personnel to identify faults, as well as the ability to deal with faults and strive to bring out the best performance of the use of machinery and equipment.