Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-07

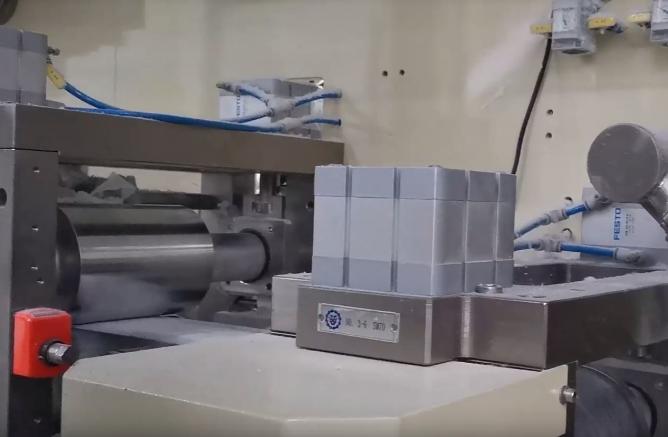

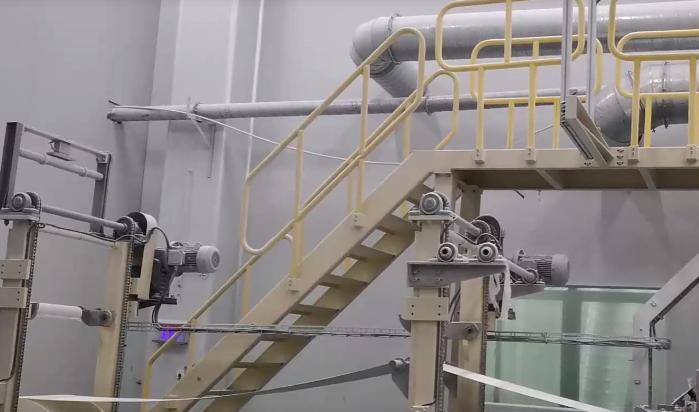

Some technical points involved in the installation of the disposable nappies making machine are very detailed and strict, because no matter which link has a problem, it will not only affect the subsequent normal operation of the whole equipment, affect the service life, but also threaten the life safety of the operators. Therefore, both users and installers of diapers making machine should pay attention to the whole installation process of disposable nappies making machine. Installers should ensure their excellent operation technology, and users should choose parts with good quality. Only by doing these well can they fundamentally ensure normal operation.

(1) Prepare construction conditions

Preparation of construction conditions is an important prerequisite for the installation work. Therefore, before we carry out the installation work, we must make the corresponding installation plan of disposable nappies making machine and review the technical conditions before installation, and take this as the theoretical basis and support for the subsequent installation construction.

(2) Do a good job of inspection

Because there are often some uncontrollable factors in the process of production and transportation of equipment by manufacturing enterprises, which leads to some problems that will cause trouble to the installation of the nappy making machine, such as some damage and the loss of some parts. This reflects the necessity of testing. If these flaws are not found, unnecessary problems will be caused to the installation work.

(3) Assess construction personnel

The construction personnel are the core part of the installation process, so it is necessary to carry out a comprehensive technical assessment of their technical ability. Among them, the professional application technology and the implementation level of technology are the key aspects of the assessment. Through the technical assessment of the construction personnel, the efficiency and reliability of the installation work can be guaranteed, which is also the focus of the preliminary preparation work.

(1) The bearing temperature is too high. The reason for this problem lies in the abnormal bearing, inadequate lubrication or cooling, etc. due to various types of reasons, it needs to be determined in many ways, such as listening, visual inspection, hand touching, etc. replacing the bearing, reducing the amount of oil and setting compressed air cooling are all effective measures to solve this problem.

(2) Bearing vibration problems. Once the vibration amplitude of the bearing exceeds the standard range, it is mostly caused by its own reasons, such as substandard parts, excessive manufacturing errors and installation problems. Facing this situation, we can solve the above problems by strengthening the production of bearings and reasonably installing components.

(3) Debugging problems. In the process of motor commissioning, there is a lack of supervision on the quality operation of disposable nappies making machine, and new technologies cannot be effectively used, which makes the installation and commissioning insurance agencies and installation supervision agencies lack clear technical guidance.

(4) Technical issues. China has not yet established a system technology platform, and the installation of disposable nappies making machine is lack of scientific and technological support, which is not only not conducive to electromechanical installation and development, but also reduces the utilization efficiency. In addition to the above reasons, the current problem of the equipment itself will also lead to various faults. The unreasonable operation behaviors of operators in actual work will lead to the occurrence of overcurrent problems, which will greatly restrict the implementation of subsequent installation work and expand the hidden dangers of installation.

The installation of disposable nappies making machine is very strict, and any problem in the installation process will affect the normal operation. Therefore, installation personnel should pay attention to continuous learning of installation technology, pay full attention to the installation process, and avoid hidden dangers of installation.