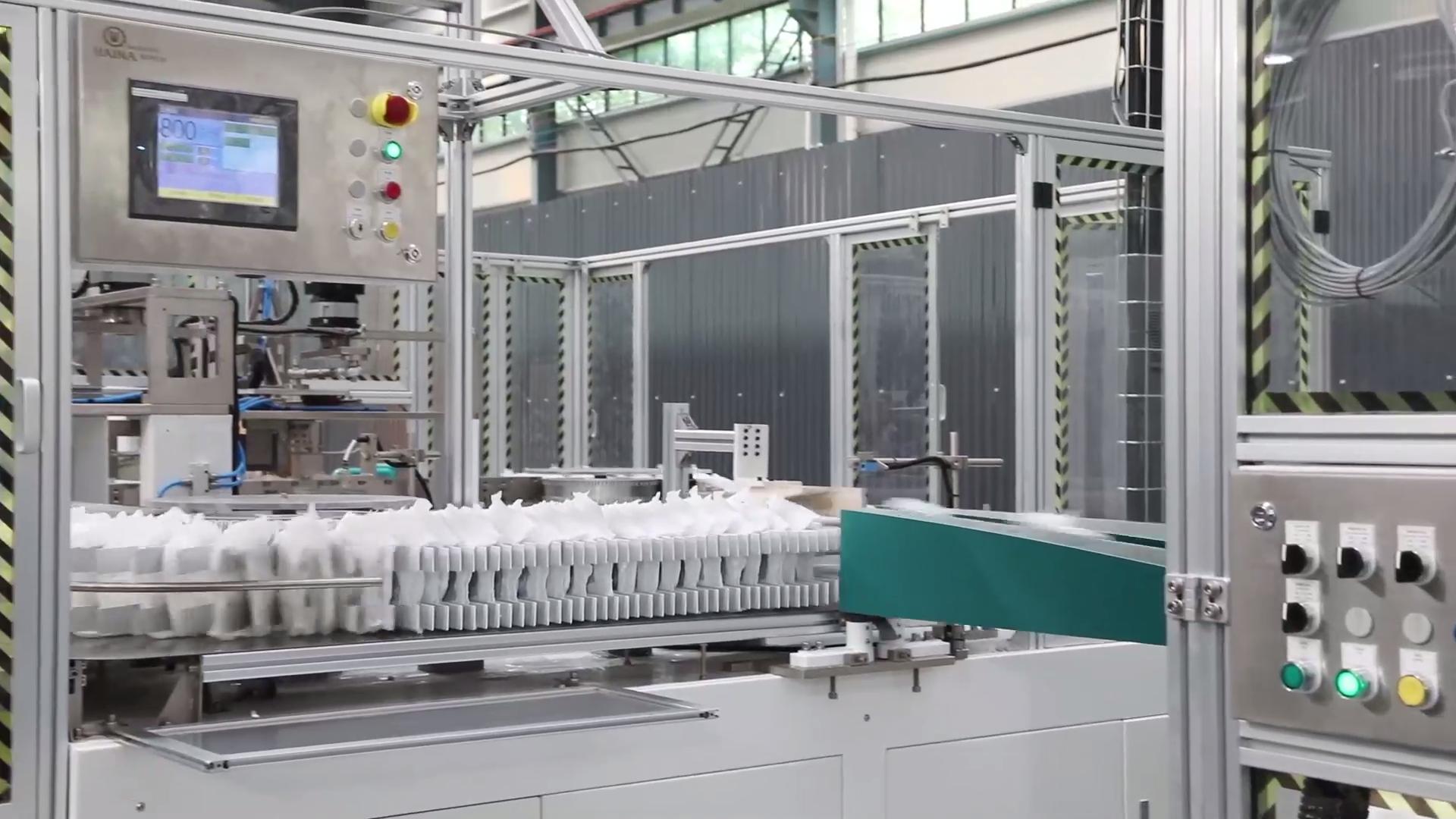

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-12

The repair and maintenance of adult diaper making production line is the basic work of equipment maintenance, which must be institutionalized and standardized. For the regular maintenance of equipment, work quotas and material consumption quotas should be formulated and assessed according to the quotas. adult diaper making machine Regular maintenance work should be included in the assessment content.

adult diaper making equipment. The daily inspection is the basis of equipment repair and maintenance. In order to ensure that the repair and maintenance of mechanical equipment meets the production needs, it should be standardized and institutionalized in the daily maintenance work. The adjustment, cleaning and maintenance of each part of the mechanical equipment must be carried out in strict accordance with the equipment maintenance and maintenance specifications to ensure the unity of maintenance content. For different mechanical equipment, it is necessary to formulate different maintenance process regulations, and maintain them in strict accordance with the regulations.

During daily inspection, it is also necessary to fully consider different working conditions according to different equipment, specify different maintenance times and strictly implement them, so as to ensure that problems in mechanical equipment can be found in time during the daily inspection process, and repaired in time to avoid repairs. big loss.

adult diaper making equipment. Regular maintenance and daily maintenance are directly related to the working conditions of machinery and equipment. Therefore, the project needs to strictly implement the maintenance system of machinery and equipment, adhere to the principle of "maintenance and prevention first", and carry out regular maintenance of machinery and equipment in the factory. and maintenance. For the same type of mechanical equipment, the project needs to arrange equipment maintenance rules and clarify the responsibilities, so that the maintenance and maintenance of various mechanical equipment can be based on, and ensure that the maintenance and maintenance of mechanical equipment are standardized. The project needs to designate a special person in charge, set up a repair and maintenance organization, supervise the implementation of the repair and maintenance system of the mechanical equipment in the factory, ensure that the mechanical equipment can be discovered and solved as soon as possible when problems occur, and ensure the normal operation of the mechanical equipment. , improve the production efficiency of machinery and equipment, and create greater economic benefits.

adult diaper making equipment maintenance personnel need to have an in-depth understanding of the performance and working conditions of the equipment on the basis of being familiar with the equipment manual. At the same time, they also need to regularly carry out professional knowledge training for maintenance personnel according to the actual situation of the project, so that maintenance personnel can theoretically To practice comprehensive learning, to further improve the technical level of maintenance personnel. The project also needs to establish a corresponding assessment system to assess the employees participating in the training, and reward outstanding personnel through assessment, so as to stimulate the enthusiasm of maintenance personnel and further improve the technical level of maintenance personnel.

To sum up, good adult diaper making production line production equipment, coupled with correct maintenance, can improve the service life of production equipment.