Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-12

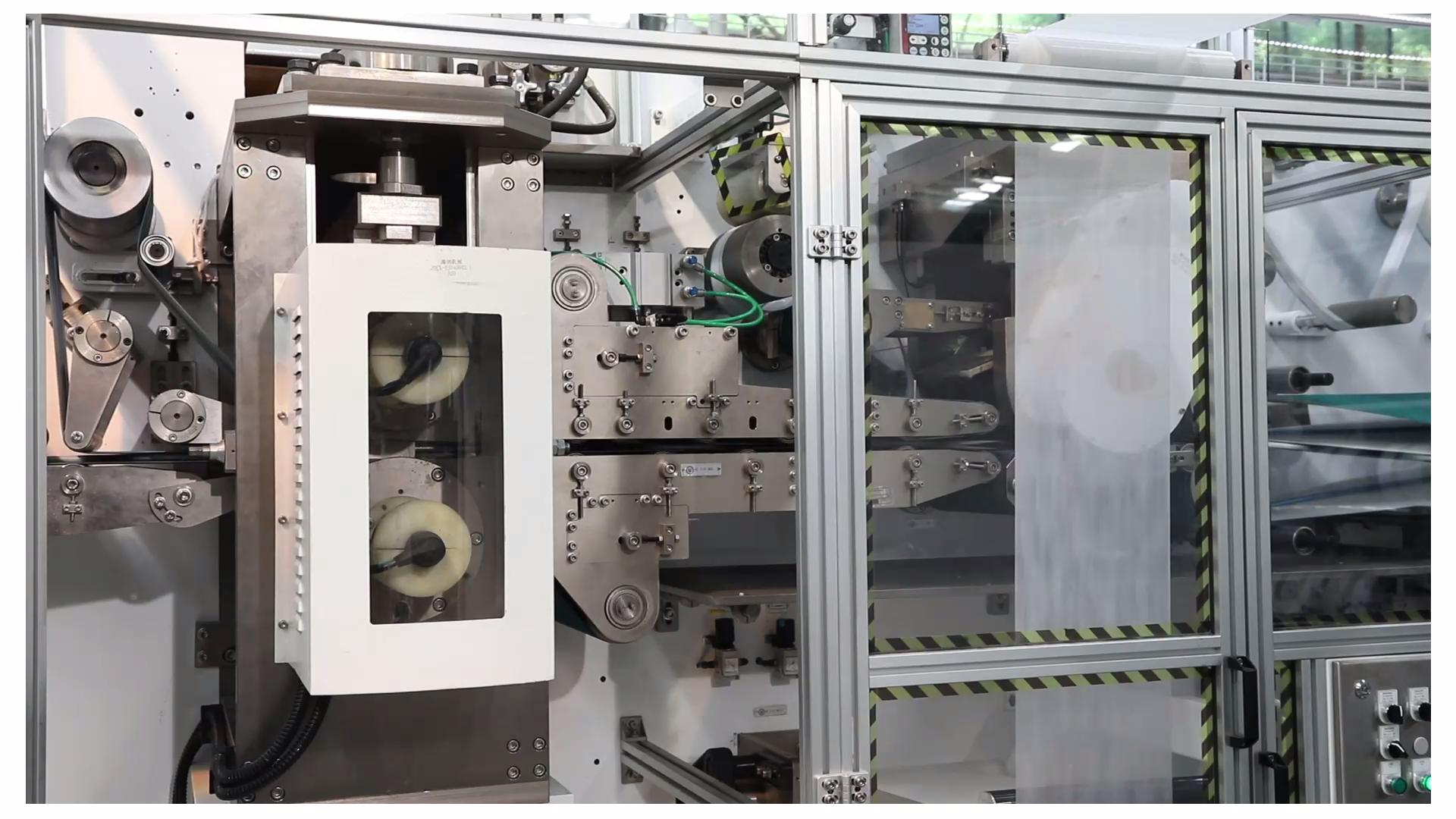

Baby diaper production line In the process of use, hidden faults often occur, resulting in interruption of production activities, which requires regular maintenance and repair of mechanical equipment, so as to play a preventive role and ensure efficient production efficiency. Failure to maintain and maintain the baby diaper make machine for a long time will cause wear and tear of parts. Once a failure occurs in production, the losses will be more serious.

Some maintenance and maintenance workers do not have skilled operation skills, which will also affect the maintenance and maintenance of equipment to a certain extent. Only by ensuring the performance of mechanical equipment can the production efficiency of the project be effectively improved. Therefore, the maintenance and maintenance of baby diaper make equipment is very important. important. Only by doing a good job in the repair and maintenance of the equipment can the integrity rate, utilization rate and productivity of the mechanical equipment be improved, the use cost of the mechanical equipment can be reduced, and the service life of the equipment can be extended.

First of all, the current engineering enterprises lack the awareness of repairing and maintaining machinery baby diaper make equipment. This lack of awareness actually reflects that the relevant workers do not consider the problem in the long-term interests, and blindly require the equipment to work overloaded for a long time. It doesn't matter as long as there is no problem, but once a problem occurs, the degree of damage to the mechanical equipment is often quite serious, but it will cause greater economic losses to engineering production.

These problems are caused by the lack of awareness of maintenance and maintenance. Machinery and equipment have been in an unsafe production state for a long time, which has actually laid a great hidden danger for production activities. Secondly, in the production activities, there is a lack of the necessary responsibility system. The implementation of the responsibility system is actually the basis for the maintenance and maintenance of machinery and equipment. In the process of engineering, even if there are some systems as a support, it has become a superficial effort and has not really do it right. Therefore, the mechanical equipment cannot be properly maintained and maintained. In addition, the professional ability of equipment operators varies, so it is impossible to correctly determine the actual situation of mechanical equipment at the first time.

Some problems are not observable on the surface, which also creates a certain obstacle for the maintenance and repair of the baby diaper make equipment. The maintenance personnel did not do regular inspections, and the wear and tear of the equipment would therefore be more serious. In this case, managers did not strictly manage the repair and maintenance system, and even the evaluation standards for equipment status were not uniform. Therefore, these problems are the reasons that affect equipment repair and maintenance, and are also the current status quo.

In order to solve the above problems, it is also necessary to start from the actual situation to prevent more serious damage to the mechanical equipment. Affected by the personal ability of mechanical equipment maintenance personnel, the current mechanical equipment repair and maintenance work is not in place. Because in the environment of the development of the times, the types of mechanical equipment are showing an increasing trend, and these equipments all use new technologies and new functions, so this requires equipment repair and maintenance personnel to have higher quality, master the latest Maintenance technology, so as to solve the failure of mechanical equipment.

Under the requirements of high standards, the current baby diaper make equipment operators generally do not have such capabilities. It can be said that the integrity rate and utilization of equipment are closely related to the operator's personal technical level. In order to avoid damage, it is necessary to The maintenance personnel of the equipment should pay attention to their technical level. At present, the technical level of many equipment maintenance personnel is uneven, so it will affect the maintenance and maintenance effect of the equipment, resulting in the inefficiency of engineering production. high.

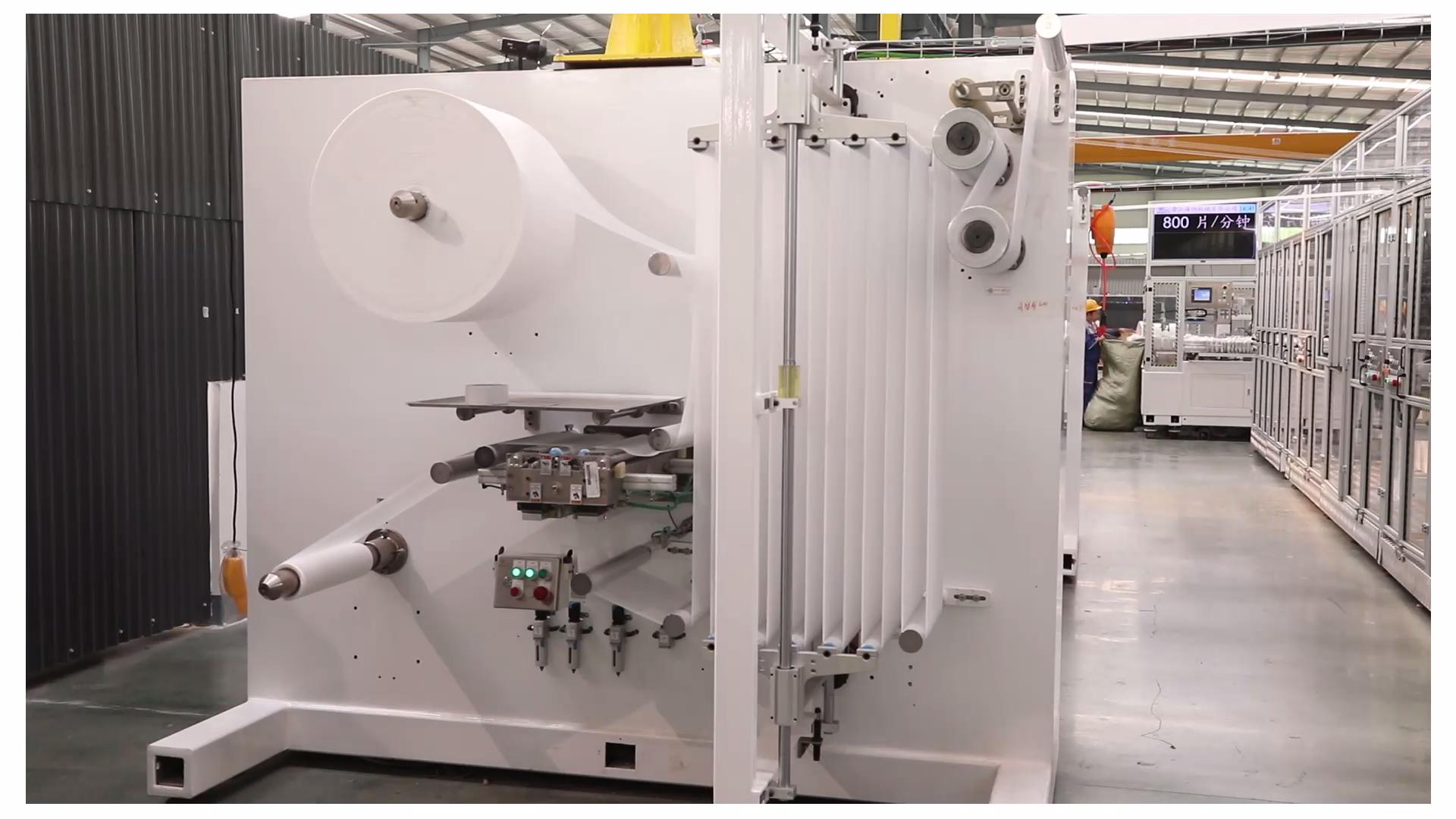

Baby diaper production line. The daily inspection is the basis of equipment repair and maintenance. In order to ensure that the repair and maintenance of mechanical equipment meets the production needs, it should be standardized and institutionalized in the daily maintenance work. During daily inspection, it is also necessary to fully consider different working conditions according to different equipment, specify different maintenance times and strictly implement them, so as to ensure that problems in mechanical equipment can be found in time during the daily inspection process, and repaired in time to avoid repairs. big loss.