Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-13

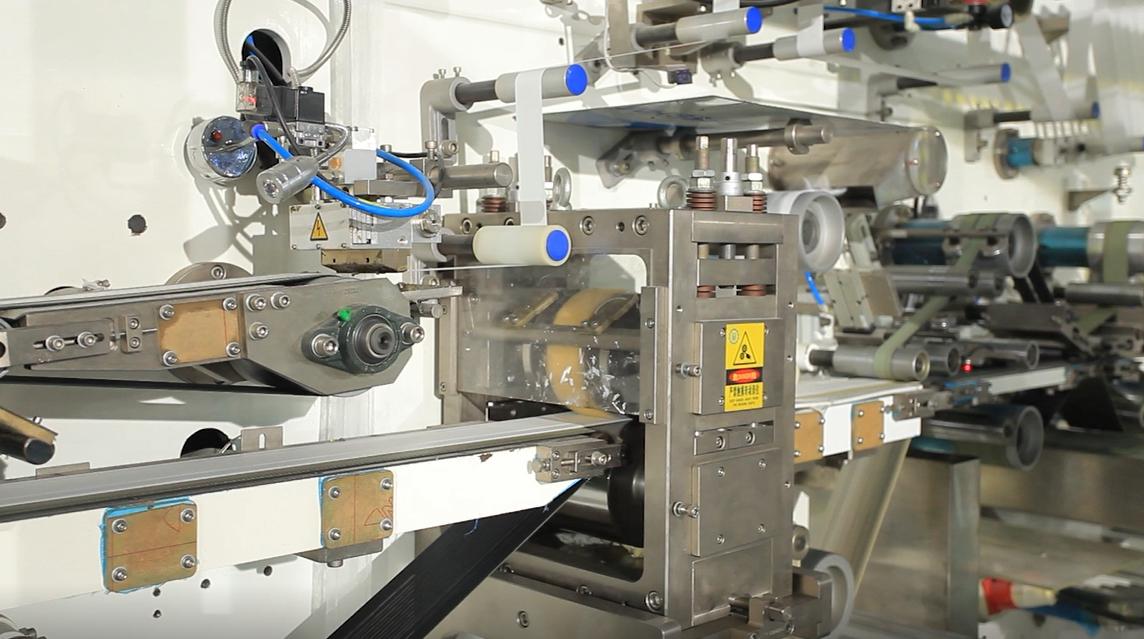

In the new era, more and more lady diaper making production lines have been developed and used. At the same time, the performance requirements of production activities on equipment are also increasing. Therefore, it is very important to ensure that the machinery has a good running state. In the use of machinery, it is often affected by many factors, resulting in some faults. In order to avoid this kind of situation, we need to do a good job in its diagnosis and monitoring.

During the operation of lady diaper making production line, the generation of vibration is inevitable. There are often periodic vibration and random vibration. The vibration will lead to the generation of a certain amplitude, which represents the vibration intensity and energy. Therefore, the frequency is an important feature of mechanical vibration. Therefore, the fault diagnosis of female diaper making production line can be realized through vibration monitoring.

With the help of corresponding instruments, the real-time situation of mechanical vibration can be monitored, and then the fault diagnosis can be completed. The commonly used monitoring instruments include magnetoelectric velocity sensor, piezoelectric acceleration sensor and eddy current displacement sensor. Because the piezoelectric acceleration sensor has the advantages of high sensitivity, wide frequency range and small volume, it has been widely used. In the vibration monitoring and diagnosis of machinery, it is not only necessary to use sensors, but also combined with analytical instruments and expert system for fault diagnosis. This method is generally used when there are faults such as gears in lady diaper making production line.

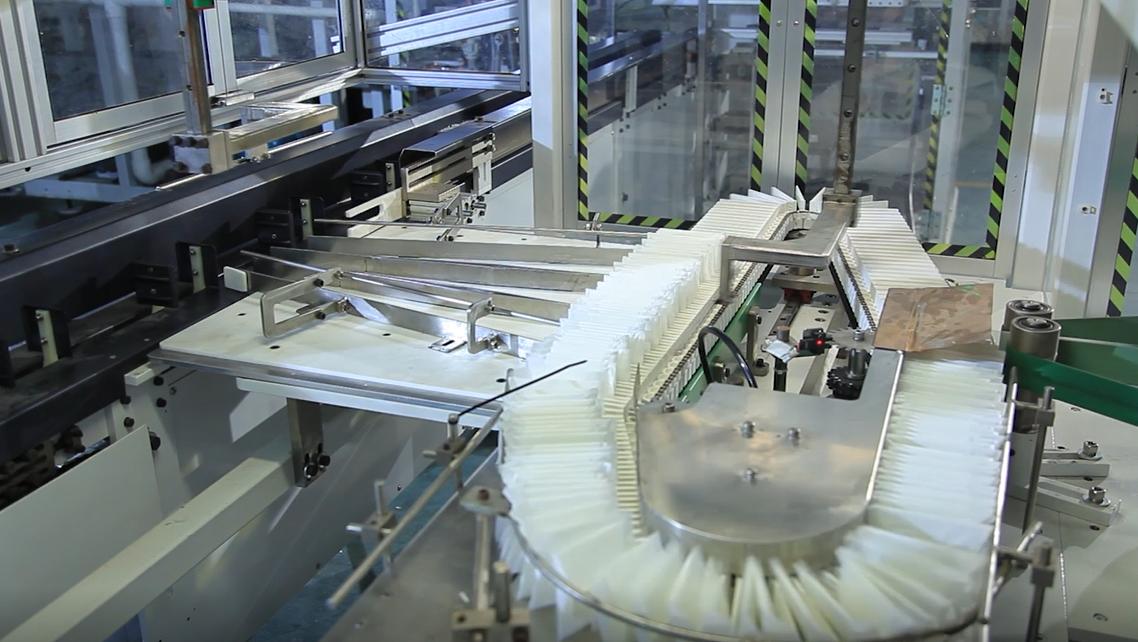

In the operation of lady diaper making production line, the equipment noise signal and vibration signal have a lot of information. Therefore, the diagnosis of mechanical fault can also be realized through the monitoring of mechanical noise. Often, the monitoring of vibration signals requires the installation and rotation of corresponding monitoring instruments. It is not easy to install in high temperature or high corrosion environment, so the contact measurement of vibration cannot be realized, and the noise signal will not be affected by this situation. Under any condition, the acquisition and analysis of acoustic signals can be realized with the help of acquisition equipment, so as to realize the effective diagnosis of faults.

In the use of this method, the infrared temperature measuring instrument is mainly used to analyze and judge its operation state according to different temperatures and temperature changes in different positions of female diaper making production line. The principle of infrared temperature measuring instrument is mainly the law of blackbody radiation, that is, the higher the temperature of the object, the stronger the ability of infrared radiation. If some parts of lady diaper making production line fail, they will often show the characteristics of temperature rise, which will prompt that there are faults such as smoke exhaust pipe blockage, wear or contact burning at this position.

Many diagnosis and monitoring methods are used in the fault control of lady diaper making production line. These methods have different principles and advantages. With the development of the times, in order to better realize the equipment fault diagnosis and monitoring, it is necessary to grasp the development trend of equipment fault diagnosis and monitoring in the research, and do a good job in the continuous research and improvement of monitoring and diagnosis methods in relevant directions, This is also the key research content in its field.