Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-02-17

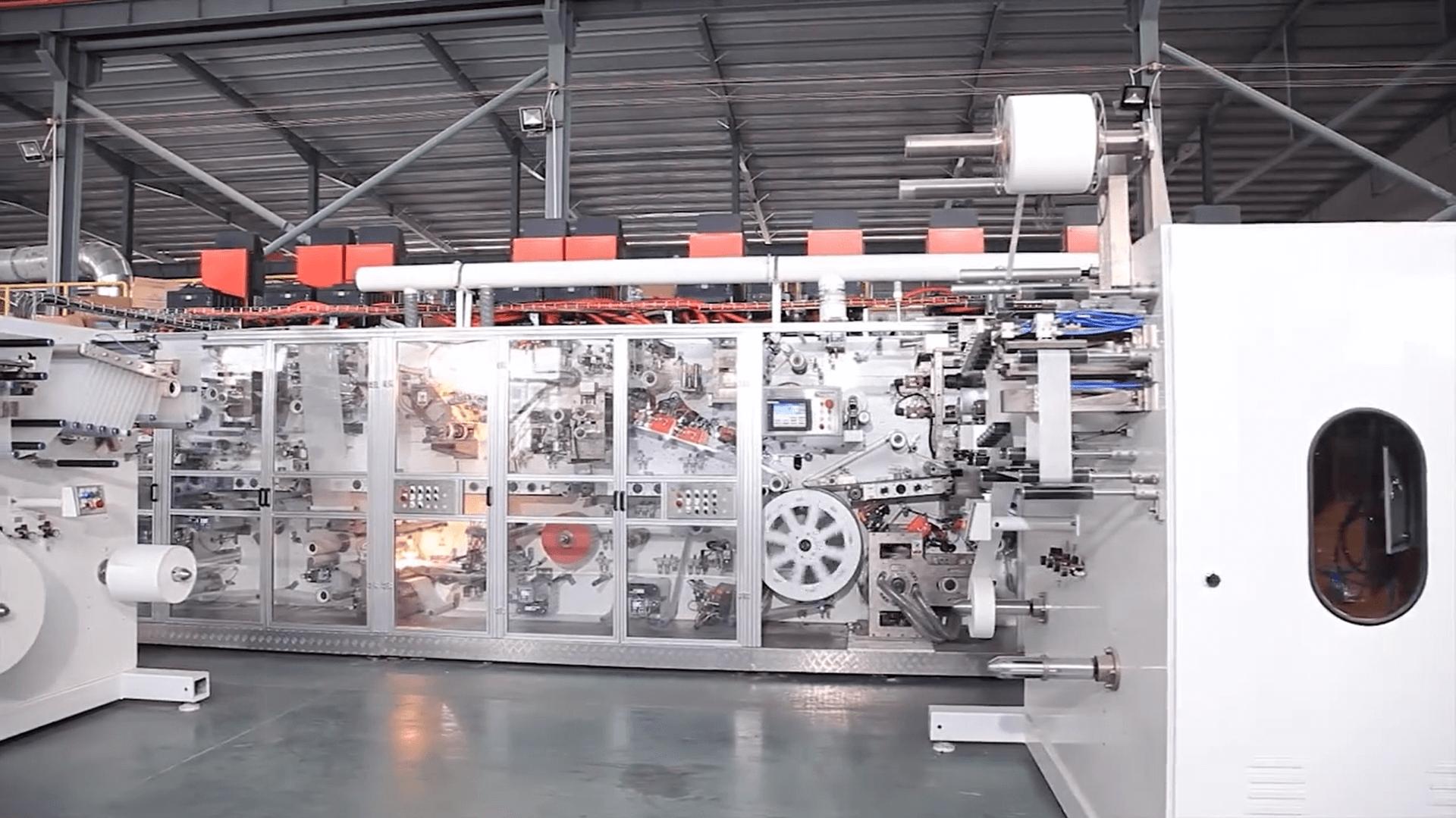

The important task of diaper production machine management is to try to prolong the normal wear stage of the equipment, reduce the wear value and shorten the wear speed as much as possible, and use advanced technologies such as lean management to detect the wear condition of the equipment and prevent the occurrence of equipment faults. diapers machine management is a daily work. Managers should check the contents of the equipment every day.

Equipment archives are the most basic records of equipment life, recording the whole process of an equipment from planning, design, manufacturing, to use, maintenance, transformation, renewal and scrapping. As a diaper production machine equipment manager, on the one hand, we should obtain the equipment management data through it; On the other hand, we should constantly improve and complete it. Integrity refers to making detailed records of the operation and maintenance of new equipment in time for future reference. At the same time, whether in terms of energy conservation and consumption reduction or safe use, it should be revised in time after obtaining the approval of the superior competent department.

(1) Correctly formulate maintenance standards and strictly implement them

There are two main maintenance standards for diaper production machine: spot inspection standard and lubrication standard. Spot inspection is to formulate standards after making a correct and detailed analysis of the operating parts of the equipment, and then use various means, such as listening, seeing, touching, smelling, etc., to determine the normal operation of these parts according to the established standards and fixed personnel at fixed time. The lubrication standard should be comprehensively considered from the working environment and performance of the equipment, so as to avoid the failure to form oil film or too much oil, failure to play the role of lubrication, pollution and waste of human and material resources in the actual lubrication process.

The same equipment has different spot inspection and lubrication standards in different enterprises and periods. The equipment management personnel shall formulate them according to the place, time and experience, and shall not follow blindly. After the standard is formulated, it shall be put into production and use after joint review with production personnel and maintenance personnel, and the implementation shall be strictly supervised. It shall be regularly checked whether the records are complete and whether the operation is in accordance with the procedures. It must not be carried out carelessly.

(2) Full participation in management

Production operators are the direct users of diaper production machine. They are much more familiar with the use performance of the equipment than maintenance personnel. Therefore, they can often find the obvious problems first. For the hidden problems, the equipment management personnel formulate the standards and hand them over to them. Finally, the equipment management personnel and production management personnel jointly formulate the process operation procedures and supervise them at any time. Due to the uneven technical strength and experience of operators and maintenance personnel, it should be appropriate for people in the process of equipment maintenance. Classification a, B and C can also be adopted, which corresponds to the professional ability and ideological level of technicians one by one according to the importance and complexity of the equipment.

(1) Improve personnel quality. We can comprehensively improve the technical level and management level of equipment managers by means of self-study, further study and teaching, and improve the professional ability and ideological and political level of maintenance personnel through multiple channels and levels.

(2) Reasonably arrange the time and content of major, medium and minor repairs. Preparations shall be made in the early stage, including pre repair inspection, spare parts preparation, network formulation, standard formulation, financial budget, etc., to ensure that the maintenance task is completed with the shortest construction period and the least capital.

(3) Diaper production machine equipment must not work with disease. In case of equipment failure, personnel shall be organized to repair immediately, and operation with disease shall not be allowed. For important parts, strict maintenance standards shall be formulated to give guidance and correct constraints to maintenance personnel.

(4) Maintenance quality inspection. After equipment maintenance, equipment management personnel and production technicians shall conduct structural inspection and accuracy inspection together. Structural inspection is to check whether the repaired equipment is complete and whether there are omissions. Accuracy check is to check whether the repaired equipment maintains the original accuracy and performance.

The most important thing is that the diaper production machine manager should know the inventory of spare parts like the back of his hand, master its service life through the analysis of its convenience records, and provide the procurement plan to the supply department in time in combination with the market sales situation and production cycle. At the same time, after the spare parts arrive at the warehouse, the side measurement and maintenance personnel with face shall be organized to check them.