Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-02-17

Through the understanding of the basic parameters, technical requirements and normal working conditions of menstrual pads machine, further judge the product standard provisions of menstrual pads machine.

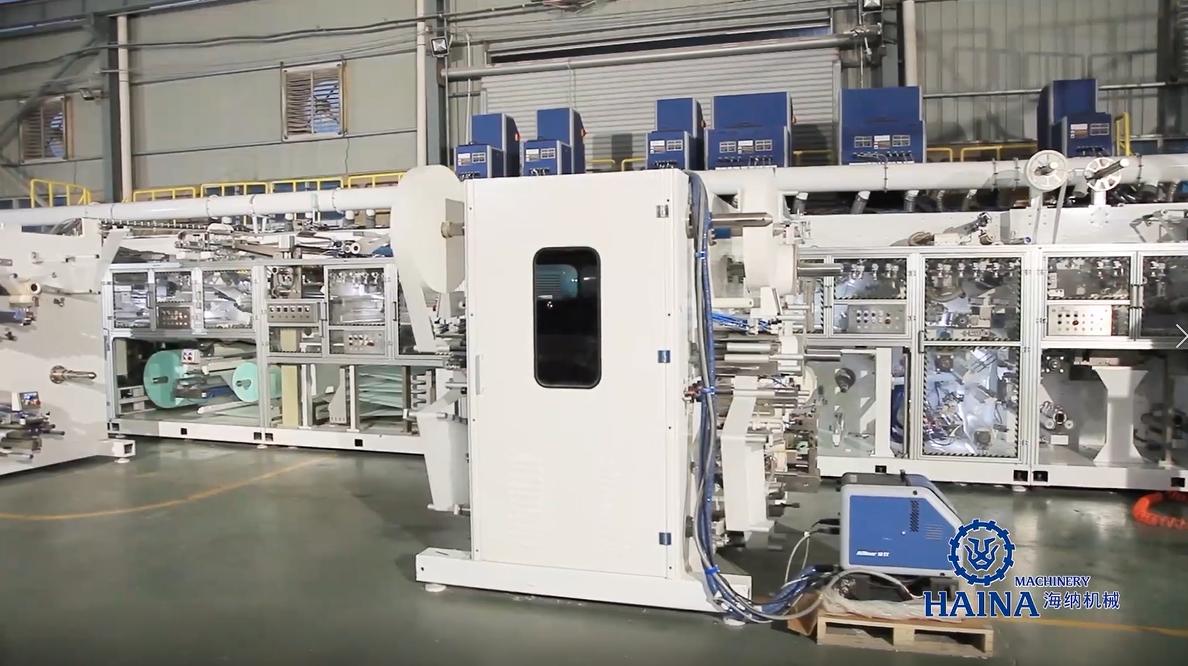

The period pad machine is mainly composed of the following systems (different types of menstrual pads production line have different system composition according to the structural characteristics of their products and the requirements of the demander):

(1) Feeding system.

(2) Conveying system.

(3) Deviation correction system.

(4) Tension control system.

(5) Hot pressing system.

(6) Suction system.

(7) Transmission system.

(8) Phase adjustment system.

(9) Sizing system.

(10) Packaging system.

(11) Electrical system.

(12) Waste suction system for leftover materials.

(13) Camera system.

(14) Cooling system.

(15) Waste removal system.

(16) Dust removal system.

(1) Service conditions

All period pad machines that meet the requirements of this standard shall work normally under the following conditions.

(2) Environmental conditions

Temperature: in the range of 5c-40c: for special environment, it needs to be put forward in additional requirements.

Humidity: when the maximum temperature is 40C, the relative humidity shall not exceed 50%. High relative humidity is allowed on the low temperature side (e.g. 90% at 20c).

Dust, acids, corrosive gases, salts and other pollutants in the surrounding air shall not exceed the normal content. The altitude shall not exceed 1000m. Quality of power supply network: the fluctuation of power supply voltage shall not exceed 10% of its rated value, the frequency shall be 50Hz or 60Hz, the unbalanced voltage, and the negative sequence and zero sequence components of three-phase power supply voltage shall not exceed 2% of the positive sequence components.

Basic Requirements

(1) Follow the principles of beautiful appearance, reasonable layout, compact structure, complete configuration, simple operation and convenient maintenance.

(2) Comply with the provisions of this standard and manufacture according to the drawings and technical documents approved by the specified procedures.

(3) The appearance of menstrual pads production line shall be clean, flat and free of dirt, and there shall be no obvious bumps, scratches, burrs and other phenomena.

(4) The edge of the assembly joint surface of all parts shall be flat without obvious dislocation.

(5) All raw materials, standard parts and accessories of the equipment shall comply with the provisions of national and relevant industrial standards.

(6) The weldments shall be firm and reliable, and the welds shall be flat and uniform without missing welding, burns, cracks, pores and other defects.

(7) The fasteners shall be firm and reliable without loosening, and the operating parts shall be flexible without abnormal sound.

(8) All pneumatic systems shall comply with the provisions of GB / T 7932, and the action shall be flexible and reliable without air leakage.

(9) The die wheel and external cutter of the equipment shall be able to be replaced according to different sanitary napkin specifications.

(10) The exposed parts of electrical lines and pipelines shall be reasonably arranged, neatly arranged and firmly installed, and shall not contact with relatively moving parts.

(11) The painted surface shall be uniform, consistent in color, shiny and free from defects such as wrinkle, peeling, paint leakage, flow mark, bubble and so on.

(12) The circular runout of roller moving bodies such as cutting tools must meet the requirements of the drawing.

To sum up, menstrual pads machine must meet the standards before it can be put into use.