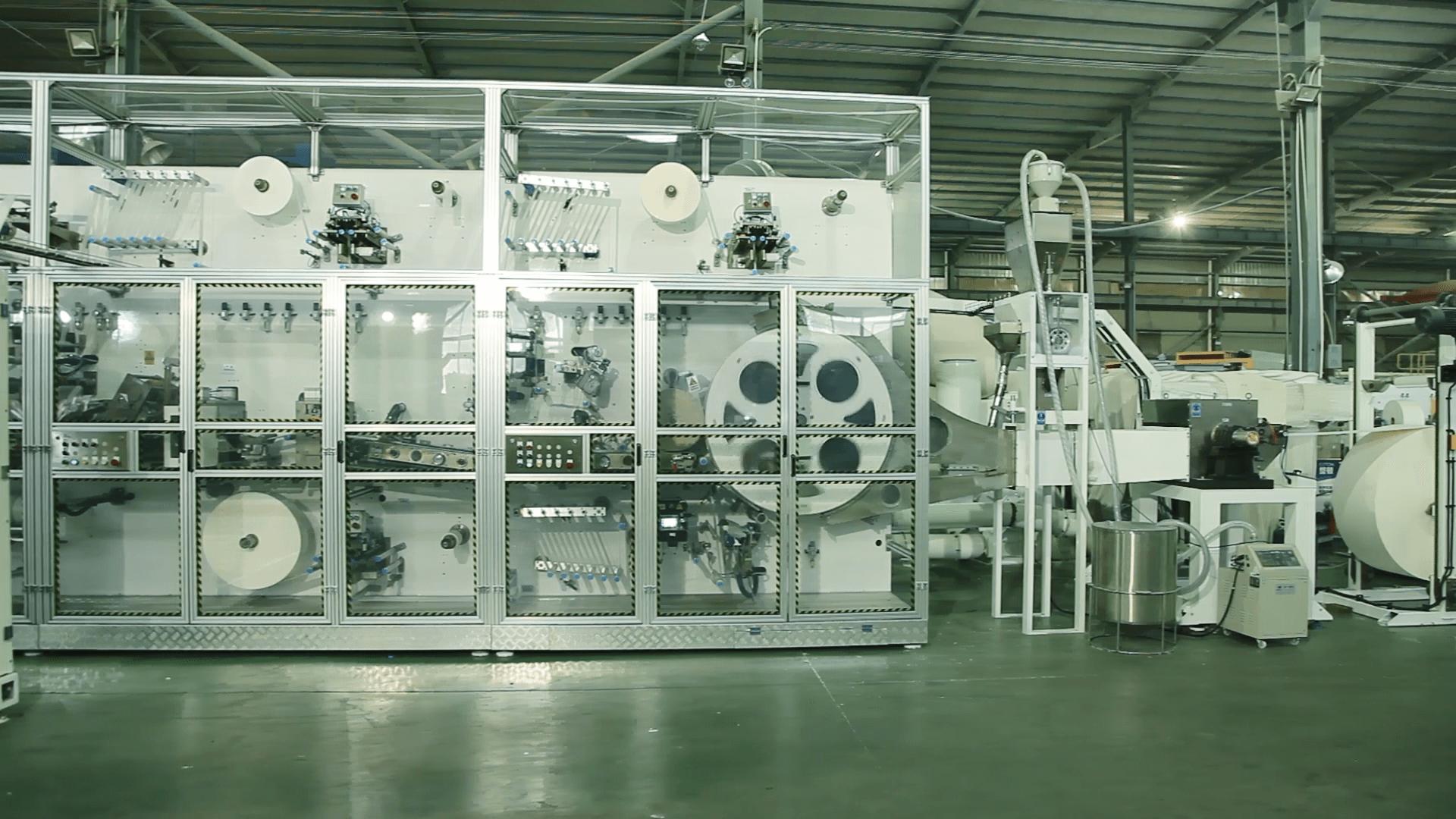

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-09

Nappy manufacturing machine Failures such as deformation, fracture, corrosion of parts caused by normal wear or physical and chemical changes of parts, also known as natural failures. In order to prevent nappy manufacturing equipment failures, the equipment should be inspected as a whole.

The whole machine inspection is the inspection of the technical condition of the whole machine. Including mechanical working ability, power and economic performance, etc., the inspection methods are as follows:

This method is simple, feasible and widely used to test and judge only by seeing, touching, and hearing. It can be divided into:

(1) Visual inspection method: The surface damage of parts such as roughness, grooves, cracks, scratches, peeling (peeling), fractures, as well as large and obvious deformation of parts, severe wear, surface annealing and ablation, etc. are all inspected visually or with the aid of a magnifying glass. Observation confirmed. There are also paint film rupture, elastic coupling dislocation, threaded connection, riveted sealing paint film rupture, etc.

(2) Percussion method: For the inconspicuous cracks of the casing parts, the combination of the bearing alloy and the bottom tile, etc., the quality can be judged by percussion listening to crisp or hoarse sound.

(3) Comparison method: compare the new standard parts with the inspected parts to identify the technical status of the inspected parts. Such as the free length of the spring, the length of the chain, the quality of the rolling bearing and so on.

Wear or deformation of parts will cause changes in size and shape, or technical performance (such as elasticity) decline due to fatigue. It can be measured by measuring tools and instruments and compared with the allowable standards to determine whether to continue to use, or to be repaired or scrapped. For example, measuring rolling bearing clearance, temperature rise, gear wear, spring elasticity, etc.

The detection of hidden defects of parts, especially minor defects of important parts, is of great significance to ensure the quality of repair and safety of use, and must be carried out carefully. There are mainly the following methods:

(1) Penetration display method: Immerse the cleaned parts in kerosene or diesel for a while, take out and wipe the surface dry, sprinkle a layer of talcum powder, and then tap the non-working surface of the parts with a small hammer, if the parts have cracks When the vibration caused the oil immersed in the crack to seep out, the talc at the crack showed yellow line marks.

(2) Fluorescent display method: first wash the surface of the inspected part, preheat it with an ultraviolet lamp for 10 minutes, so that the surface of the workpiece is dark purple when observed under the ultraviolet lamp, and then evenly apply the fluorescent display liquid on the working surface of the part, Can show yellow-green defect traces.

(3) Flaw detection method: magnetic particle inspection, ultrasonic inspection, radiographic inspection. Mainly used to measure internal defects of parts and weld quality.

Nappy manufacturing machine The overall inspection is the comprehensive quality appraisal after the mechanical equipment is repaired, and it is an important link to ensure the good performance, safety and reliability of the semi-automatic baby diaper machine after delivery.