Understanding Sanitary Pad Machines. Materials for Organic and Biodegradable Pads. The Role of Sanitary Pad Machines in Producing Eco-Friendly Products. Challen...

Understand Your Production Needs. Evaluate Machine Features. Consider Quality and Reliability. Assess Cost Considerations. Look for Technology and Innovation. C...

Understanding Your Machine. Common Operational Issues. Material Quality Problems. Mechanical Failures. Electrical Issues. Software Glitches. Operator Training a...

Understanding the Components Needed. Conducting Market Research. Utilizing Online Platforms. Networking in the Industry. Requesting Samples and Quotes. Evaluati...

Mechanical Failures. Material Quality Issues. Operator Error. Inefficient Production Processes. Quality Control Challenges. Environmental Factors. Supply Chain ...

Types of Sanitary Pad Machines. Production Capacity. Features and Technology. Brand and Manufacturer Reputation. Installation and Delivery Costs. Maintenance an...

Lady pad machine is an innovative device designed to help women produce their own sanitary pads. It is a revolutionary product that addresses various concerns r...

1. Sanitary Pads Machine+Auto BaggerProgram System Servo driven, intelligent HMI touch screen man-machine interface 2. Tension System Tension control with buff...

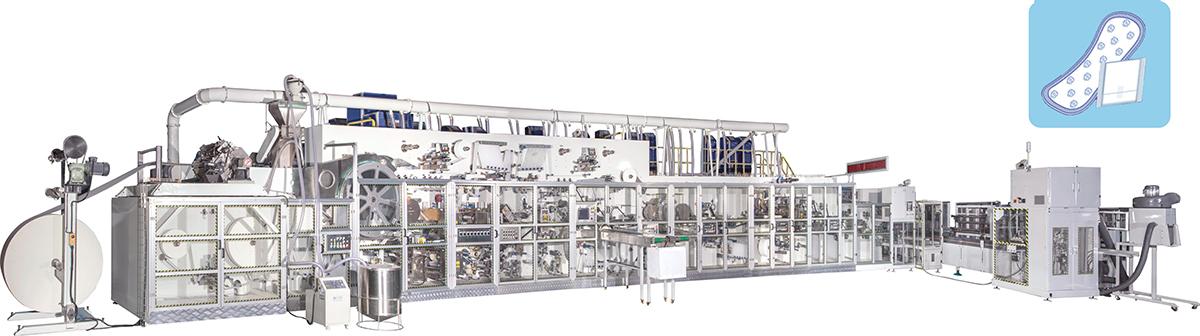

Fully automatic sanitary pad machine is a highly advanced machine that is solely designed for the production of sanitary pads. This machine is designed to ease ...

Introduction. Machine Components. Step 1: Raw Material Feeding. Step 2: Pulp Molding. Step 3: Absorption Layer Formation. Step 4: Release Paper Unwinding. Step ...

Introduction. 1. Unpacking and Inspection. 2. Machine Placement. 3. Power Supply. 4. Machine Connections. 5. Control Panel Setup. 6. Testing and Calibration. 7....

Introduction. 1. Enhanced Production Efficiency. 2. Improved Product Quality. 3. Customization Options. 4. Cost-effective Production. 5. Sustainability and Envi...

Introduction. 1. Production Capacity. 2. Quality and Consistency. 3. Automation Features. 4. Flexibility and Customization. 5. Durability and Maintenance. 6. Co...

Enhanced Production Efficiency. Precise Control and Customization. Improved Hygiene and Sustainability....

Introduction. Market Size and Growth. Trends and Opportunities. Challenges and Outlook. Conclusion....

Streamlined Raw Material Processing. High-speed Production and Packaging. Customization and Flexibility....

Introduction. Routine Cleaning and Lubrication. Inspection and Troubleshooting. Calibration and Preventive Maintenance....

1. Machine Components. 2. Production Process. 3. Quality Control....

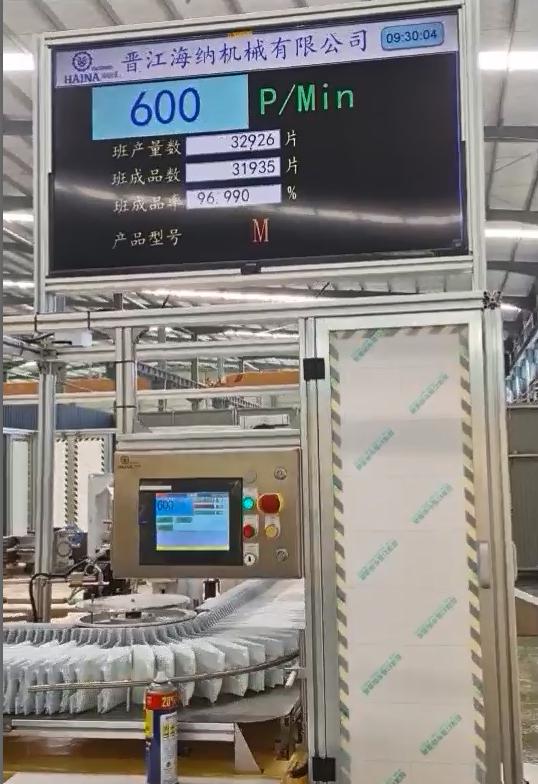

High Yield best sanitary pad machine Manufacturer Video...

The operating environment of electrical equipment on fully automatic sanitary pad machine is very special. In the specific operation process, its safety managem...

1.Adult Menstrual PantsMachine Program System Servo driven, intelligent HMI touch screen man-machine interface 2.Tension System Tension control with buffer system, automatic we...

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully au...

Overall size: 31mx4mx5m (for reference only). Product Structure: Flat(or textile edge)Topsheet,ADL(blue core), Tissue (or airlaid), Cotton core(mix with SAP), Back sheet, Release paper,...

Sanitary Napkin Production Line in Argentina, this machine only can produce 240mm one size as per customer, stable working speed is 800ppm, the core is pulp and sap which wrapped by ...

This is HAINA adult diaper machine, it is compatible with S cut ear tape and T shape big ear tape. It is able to produce adult diaper in three sizes, size M/L/XL Stable working speed ...

In order to use the familiar operation adult diaper manufacturing machine more correctly and safely, reduce equipment failures due to misoperations to ensure that equipment and faciliti...

iframe width="560" height="315" src="https://www.youtube.com/embed/DjSU1hwvS98" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-m...