1. Efficient Production Process. 2. Customization and Flexibility. 3. Enhanced Quality and Cost Efficiency....

Introduction. Growing Demand for Infant Diapers. Market Trends and Opportunities. Conclusion....

1. Regular Cleaning. 2. Lubrication. 3. Inspection and Calibration....

Introduction. Machine Functionality. Machine Components. Conclusion....

1. Proper Machine Setup. 2. Optimum Material Selection. 3. Regular Maintenance and Inspection. Conclusion....

Maintenance workers are divided into maintenance workers and mechanical maintenance workers. When infant diaper making machine malfunctions, it is often unclear...

Infant diaper making machine is widely used in manufacturing enterprises. Automatic production lines save a lot of time and cost. In cities with developed indus...

1. estrutura do produto: Tecido superior e inferior (ou airlaid), núcleo de algodão (misturado com SAP), não tecido hidrofílico da folha superior, não tecido ADL, manguito de vazam...

1. Sistema de programação da máquina de fraldas para bebês tipo T-Shape Ear Servoacionado, interface homem-máquina com tela de toque HMI inteligente 2. Sistema de tensão Controle...

The Pampers making machine is a top-of-the-line piece of equipment designed to efficiently manufacture high-quality diapers. Its advanced features include automatic feeding, cutting, an...

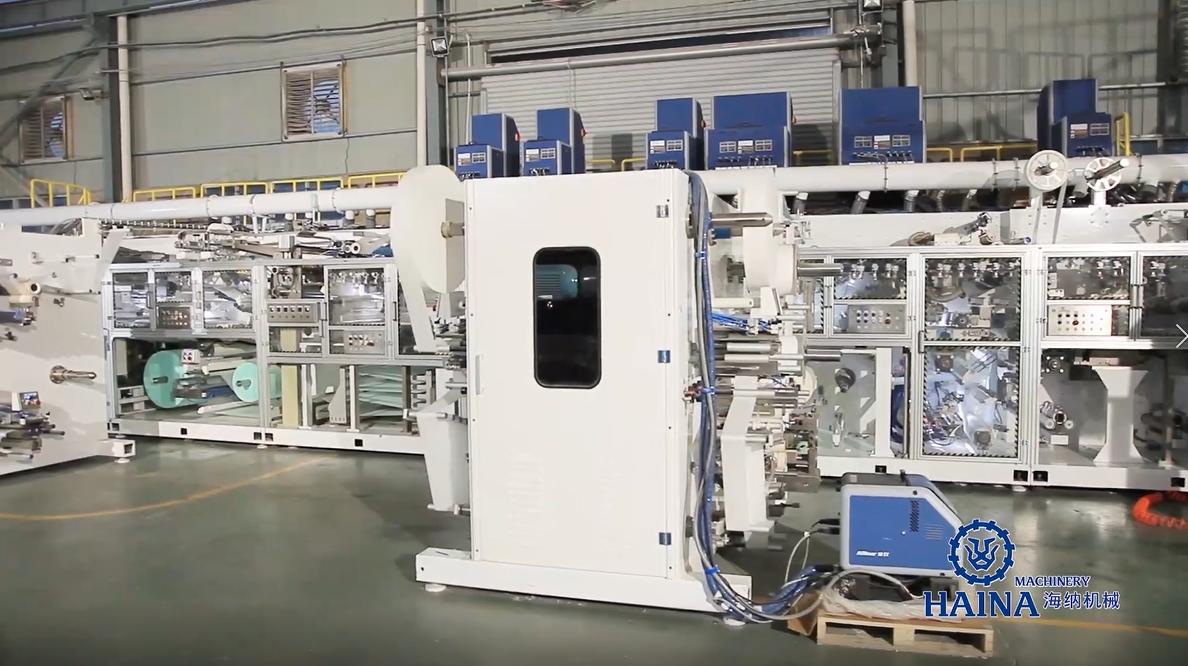

This is Haina Adult&Menstrual pants production line for Fujian Licheng Customer Stable working speed :250-300 pcs/min The customer purchased machine from Haina in 2018,Adult&Menstrual p...

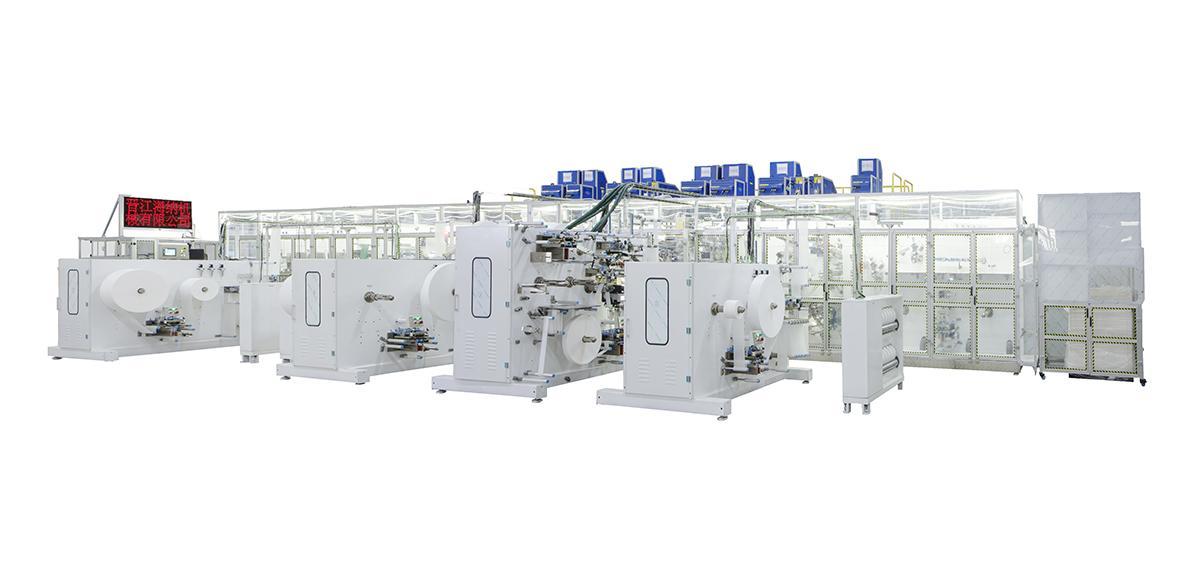

Thisis HAINA adult diaper machine. Itis able to produce baby diaper in three sizes, size M/L/XL Stableworking speed 300pcs/min for M size. Withincreasing of aging population and ...