Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-13

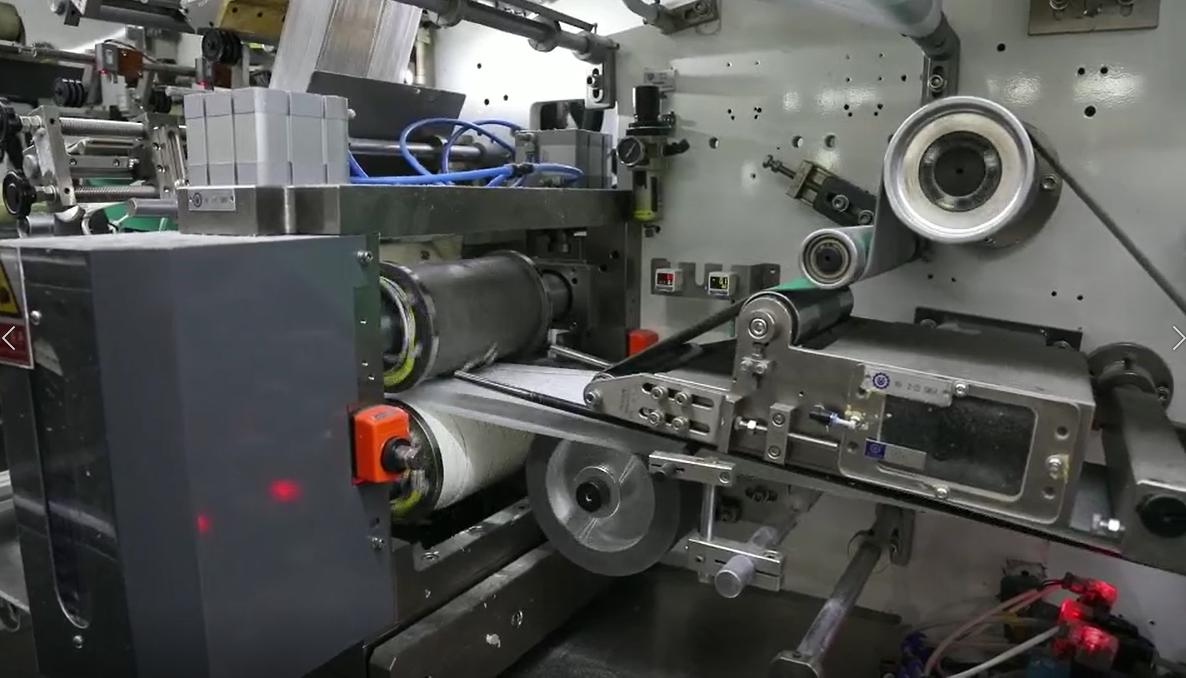

Maintenance workers are divided into maintenance workers and mechanical maintenance workers. When infant diaper making machine malfunctions, it is often unclear whether it is the responsibility of the electrical maintenance worker or the responsibility of the mechanical maintenance worker. It is necessary to fully understand the mechanical and electrical connection of the equipment, and to clarify the operation principle in order to improve the work. Efficiency and guaranteed maintenance quality. The following will briefly talk about infant diaper making equipment common methods of electrical troubleshooting.

When an electrical failure occurs in infant diaper making machine, do not blindly repair it. Before maintenance, ask, look, listen, and touch to understand the operation before and after the fault and the abnormal phenomenon after the fault occurs, so as to determine the location of the fault according to the fault phenomenon, and then accurately eliminate the fault. Q: Ask the operator about the operation status of the circuit and equipment before and after the failure and the symptoms after the failure, whether the failure occurs frequently or occasionally; whether there are signs of noise, smoke, sparks, abnormal vibration, etc.; whether there is excessive cutting force before the failure occurs Yamato frequently starts, stops, brakes, etc.; whether it has undergone maintenance and repairs or changed lines. Look: Check whether there are obvious signs of appearance before the fault occurs, such as various signals; the condition of the fuse with the indicating device; the tripping action of the protection appliance; the wiring is falling off; the contact is singed or welded; Listening: On the premise that the line can still run and the equipment is not damaged, you can test the car with power on, and listen carefully to whether the sound of the motor and other electrical appliances is normal. Touch: After just cutting off, touch and check the motor, transformer, electromagnetic coil and fuse as soon as possible to see if there is overheating.

In infant diaper making machine, the actions of electrical components are driven by machinery and hydraulic pressure or have a close linkage relationship with them. Therefore, when repairing electrical faults, check, adjust and eliminate mechanical and hydraulic parts. Repairman cooperated.

Before dealing with infant diaper making machine faults, you should have a comprehensive understanding of the structure, operation principle, adjustment method and the connection between each part of the electrical equipment. Equipment performance failures can be roughly divided into two categories: one is that the equipment cannot perform the specified actions, or fails to meet the specified performance indicators; the other is that the equipment has non-specified actions or unexpected phenomena . For the former, the conditions that should be met for the equipment to perform the specified actions and to achieve the specified performance indicators should be analyzed in principle, check whether these conditions are all met, and find out the conditions and reasons that are not met. For the latter, the conditions that need to be met to generate the fault action should be analyzed, and those undesired conditions should be checked to find out the cause of the malfunction. In a word, we should start with the analysis of the action principle of the equipment, first find the large scope of the fault, and then check it step by step, from coarse to fine, until the point of failure is finally found and eliminated. For some fault phenomena, it cannot be simply dealt with. The causes should be analyzed according to the location of these phenomena, and the problem should be determined through step-by-step tests. Do not act rashly to expand the failure, or cause personal or equipment accidents.

In infant diaper making machine maintenance, do a good job of on-site fault diagnosis, conduct a comprehensive analysis of the electromechanical, and use some basic principles to consider the problem, which is the premise to ensure fast and accurate fault handling. Only through continuous exploration and summary in the maintenance process can we improve work efficiency and ensure maintenance quality.