Introduction. 1. Machine Setup. 2. Material Preparation. 3. Machine Operation. 4. Maintenance and Cleaning. 5. Safety Precautions. 6. Troubleshooting. 7. Qualit...

Introduction. 1. Preparing the Machine. 2. Setting Up the Machine. 3. Loading the Raw Materials. 4. Starting the Production Run. 5. Monitoring and Adjusting. 6....

1. Preparation. 2. Machine Setup. 3. Loading the Materials. 4. Machine Calibration. 5. Start the Machine. 6. Continuous Monitoring. 7. Quality Control. 8. Maint...

Introduction. 1. Machine Start-Up. 2. Raw Material Preparation. 3. Machine Calibration. 4. Production Process. 5. Quality Control. 6. Machine Maintenance. 7. Tr...

Introduction. 1. Site Selection. 2. Machine Layout Planning. 3. Machine Installation. 4. Raw Material Storage Set-Up. 5. Machine Calibration and Testing. 6. Wor...

1. Determine your production requirements. 2. Research reputable manufacturers. 3. Evaluate machine features. 4. Consider the machine's durability. 5. Assess th...

Introduction. Step 1: Preparing the Space. Step 2: Assembling the Machine. Step 3: Connecting Power and Utilities. Step 4: Testing and Calibration. Step 5: Trai...

1. Machine Overview. 2. Preparation and Setup. 3. Material Handling. 4. Machine Operation. 5. Quality Control. 6. Maintenance and Cleaning. 7. Troubleshooting. ...

Introduction. 1. Understanding the Machine Components. 2. Setting Up the Machine. 3. Material Selection and Handling. 4. Operating the Machine Safely. 5. Monito...

Step 1: Unpacking and Inspection. Step 2: Machine Placement. Step 3: Connecting Utilities. Step 4: Assembly and Installation. Step 5: Software Configuration. St...

1. Initial Setup. 2. Material Preparation. 3. Machine Calibration. 4. Operating Procedures. 5. Maintenance Schedule. 6. Troubleshooting. 7. Quality Control. 8. ...

1. Automated Assembly. 2. Customization Options. 3. Ultra-thin Diaper Production. 4. High-Speed Production. 5. Quality Control Systems. 6. Environmentally Frien...

1. Increased Productivity. 2. Enhanced Product Quality. 3. Customization Options. 4. Cost Efficiency. 5. Improved Worker Safety. 6. Sustainable Manufacturing. 7...

1. High-Speed Production. 2. Automated Processes. 3. Customizability. 4. Quality Control. 5. Waste Reduction. 6. Energy Efficiency. 7. Product Innovation. 8. Sc...

1. Introduction to Diaper Manufacturing Machine. 2. Production Efficiency and Cost-effectiveness. 3. Customization and Product Diversification. 4. Quality Contr...

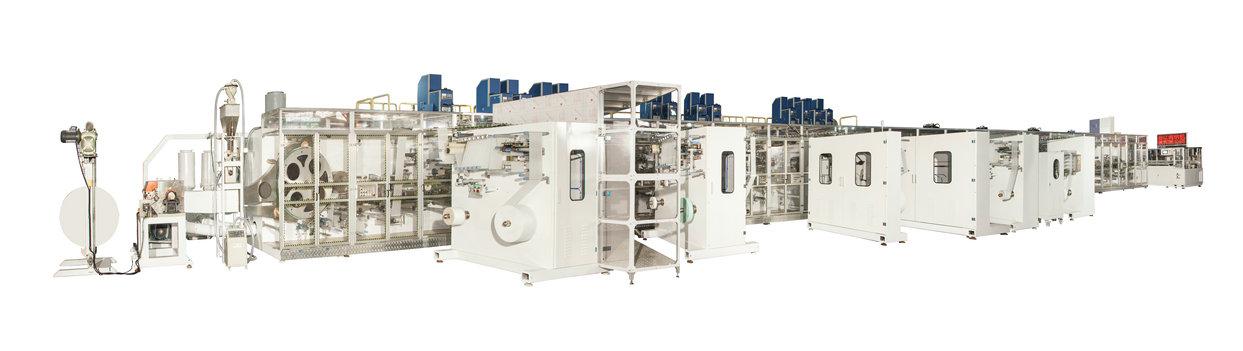

Rejection rate: ≤3%,Efficiency: ≥85%, Packaging system: Auto stacker to be defined by customer need (dual push dual exit), the stacking range: 16-36pcs/pack adjustable. Web guiding sy...

1. estrutura do produto: Tecido superior e inferior (ou airlaid), núcleo de algodão (misturado com SAP), não tecido hidrofílico da folha superior, não tecido ADL, manguito de vazam...

1.automatic adult diaper making production line Program System Servo driven, intelligent HMI touch screen man-machine interface 2.Tension System Tension control with buffer system, aut...

This is Baby Diaper Making Production Line in Ghana. It can produce four sizes of S / M / L / XL, with a stable production speed of 500 pieces / min. With the gradual development of in...

Baby Diaper Making Machine in Brazil .It can produce four sizes of S / M / L / XL, The stable production speed of M size is 550 pieces / min. With the gradual development of industri...