Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-30

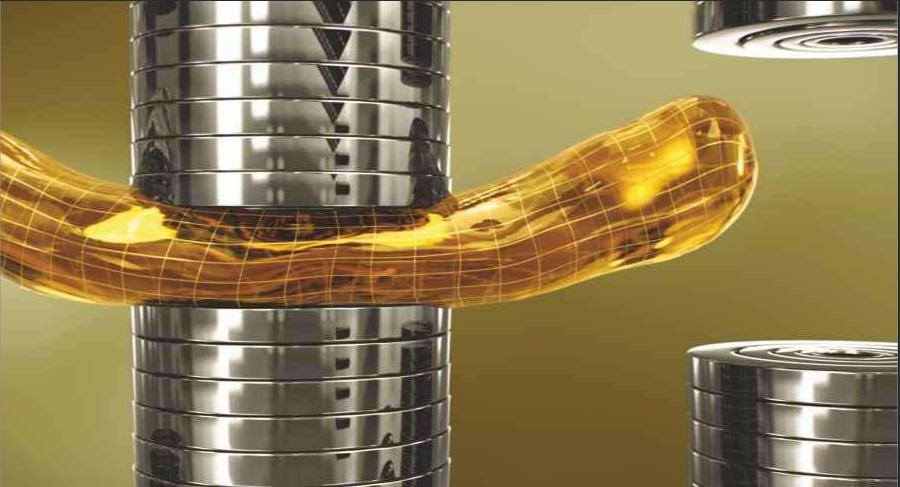

The lubrication of sanitary napkin machine manufacturers has "five-determination" rules. The so-called "five-determination" of lubrication refers to designated point, qualitative, quantitative, regular and fixed. Its meaning is as follows:

Determine the lubrication point of each equipment, and refuel, change the oil, and check the liquid level and oil flow according to the specified lubrication points and inspection points (oil mark, oil window, etc.).

According to the lubricating chart, the oil lubricating materials for grease grades must pass the test before they can be used, and there must be scientific basis when substituting and blending. Lubricating equipment, seals, etc. must be in good condition and clean, and oil should be prevented from contamination and mixing.

Change the oil or add grease in the specified amount. Implement oil consumption quota, waste recycling and return to warehouse, control equipment oil leakage, and prevent waste.

Refuel, clean and change the oil according to the time specified in the lubrication chart or lubrication card. Sampling and testing at the specified time. Perform circulating filtration according to the condition of grease, or determine the time of cleaning and oil change and the next sampling inspection or oil change.

Make clear the division of labor between operators, maintenance workers and lubricators for equipment work, and should be responsible for various equipment and equipment lubrication points, supervise each other, and cooperate closely:

sanitary napkin machine manufacturers. Lubrication management technicians should be responsible for organizing, guiding, inspecting, and supervising the "five-setting" work of lubrication. Lubricators and operators should conscientiously implement the "five-setting" work, and maintenance workers should closely cooperate with the "five-setting" work.