Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-04

In order to make equipment lubrication management work smoothly, sanitary pads making machine in south africa enterprises should establish and improve various equipment lubrication management systems

Generally, the mobile department applies for the plan according to the year, season and lubricating material provided by each workshop, and reports it to the supply department, and then the supply department purchases the plant in time according to the grades and deadlines required by the plan. After the lubricating material enters the factory, the main quality indicators of the oil should be tested by the testing department, and only if it is qualified can it be stored in the warehouse or released for use. The purchase of substitute oil by the supply department is subject to the consent of the mobile department.

Can be responsible for the recovery and recycling of waste oil in all workshops of the whole plant, responsible for the preparation of cutting fluid and lubricating oil, responsible for testing and testing lubricating oil, responsible for statistics of oil and grease consumption in all workshops of the whole plant, and responsible for promoting lubrication New technologies and new lubricant materials.

During the refueling and oil changing cycle of the equipment, the amount of supplemented oil should be recorded for each refueling and oil change, the oil leakage situation of the system should be mastered, and the oil temperature should be detected. .

Production equipment must maintain a certain degree of cleanliness according to its use and product requirements. In addition to maintaining a civilized production environment and reducing equipment pollution, necessary purification measures should be taken periodically to remove dirt accumulated inside and outside the equipment.

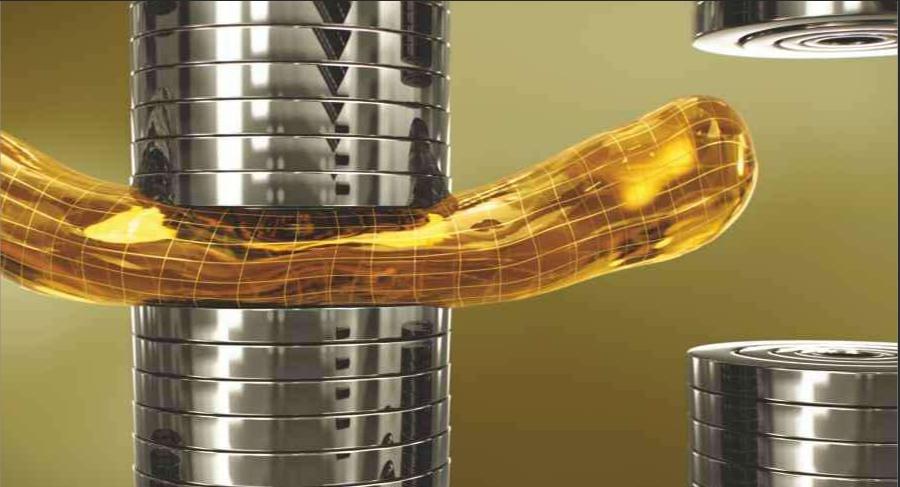

The cleaning and purification of the lubrication system is a key link in equipment maintenance. Machining chips and external impurities may remain in the lubrication system of new equipment; for equipment in motion, precipitates are formed due to the gradual aging and deterioration of the lubricating oil, and dust and debris will also be brought into the lubricating oil system during the contact between refueling and air. Therefore, whether it is new equipment or the lubrication system of old equipment in operation, it must be carefully cleaned and purified. The cleaning and purification cycle should be specified according to the size of the equipment, the importance of the equipment, environmental conditions or the results of inspection and test analysis. The cleaning and purification steps and materials used should also be selected according to the specific conditions of the system.

Both oil and purification materials have the risk of fire and explosion. In order to ensure the safety of factories, equipment and personal safety, a safety technical system for oil and purification materials must be formulated.

In order to save energy and prevent pollution and heat circulation, enterprises must formulate a management system for the recovery and recycling of lubricating oil.

Only by doing a good job of the above seven-point lubrication management system, sanitary pads machine africa companies can reduce costs, increase profits, and reduce the incidence of accidents in every link.