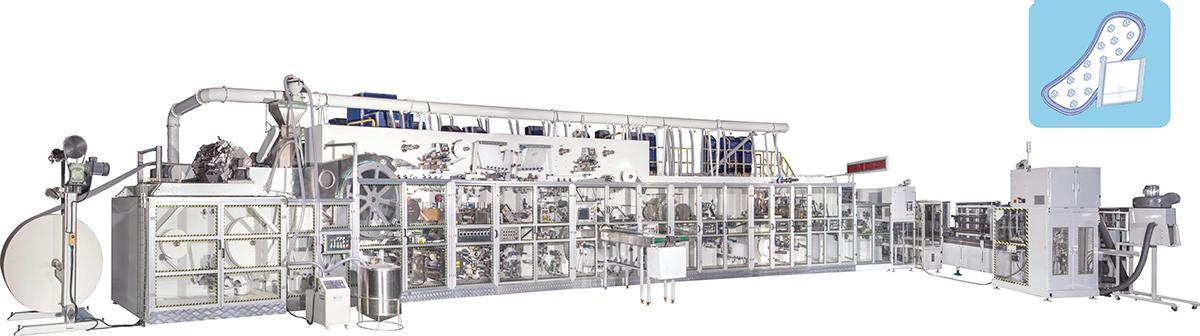

Due to the complexity and uncertainty of adult diaper machinery itself, problems of one kind or another will inevitably arise during the daily construction process, and these problems need to be dealt with in a timely manner to avoid any impact on the adult diaper making machine itself or on the overall construction.

1. Improve the management system of adult diaper machinery

In the production process adult diaper machinery management personnel should be fully aware of the importance of machinery and equipment repair and maintenance work, and in line with the relevant national requirements and standards under the premise of opening a special maintenance department and professional machinery and equipment maintenance staff. At the same time, it is also necessary to do a good job in the deployment of machinery and equipment, need to be combined with the progress and construction of the deployment of equipment to improve the overall quality and efficiency of equipment management.

2. Improve the technical level of adult diaper machinery maintenance managers

In the actual adult diaper machinery maintenance process, you can strengthen the professional level of the enterprise's relevant machinery and equipment management personnel by way of training. In the background of the development of science and technology machinery and equipment related technology update speed gradually accelerated, machinery and equipment maintenance personnel themselves are facing more and more challenges. And to ensure the level of mechanical maintenance not only need to strengthen their professional knowledge, but also need to strengthen the practical ability, for example, in the process of machinery and equipment operation can be based on machinery and equipment noise to determine the operating conditions of the equipment, if the sound appears abnormal, should promptly stop running equipment, and equipment inspection, to find out where the fault occurred and analyze the reasons for its appearance, to determine the corresponding maintenance measures.

3. Develop a reasonable adult diaper machinery handover system

Once adult diaper machinery has been put into use, it is usually subject to long hours of operation. In this situation, in order to ensure that the equipment can be long-term, stable and effective operation, it is necessary to establish a scientific and effective handover system, to ensure that 24h machinery and equipment can be under monitoring, to ensure the effectiveness and real-time management of the entire machinery and equipment. In the handover process, the handover personnel need to inspect the entire equipment, to determine the stability of the internal structure of the equipment connection and the overall condition of the parts, and then carry out targeted inspection work according to the different characteristics of different equipment.

The importance of adult diaper machinery repair and maintenance work is gradually coming to the fore, as the original level of mechanical equipment repair and maintenance work is still relatively low, and cannot provide a guarantee for the normal and effective and efficient operation of mechanical equipment. Therefore, the relevant personnel need to strengthen the importance of maintenance management of machinery and equipment.