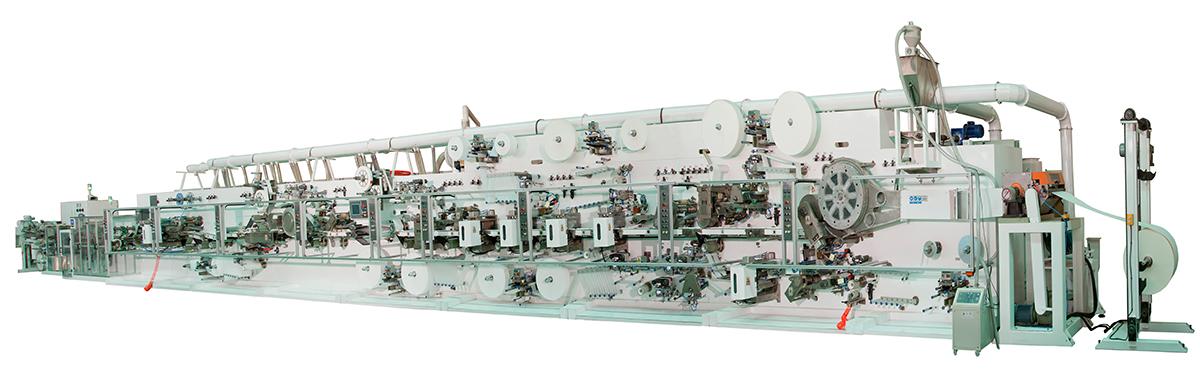

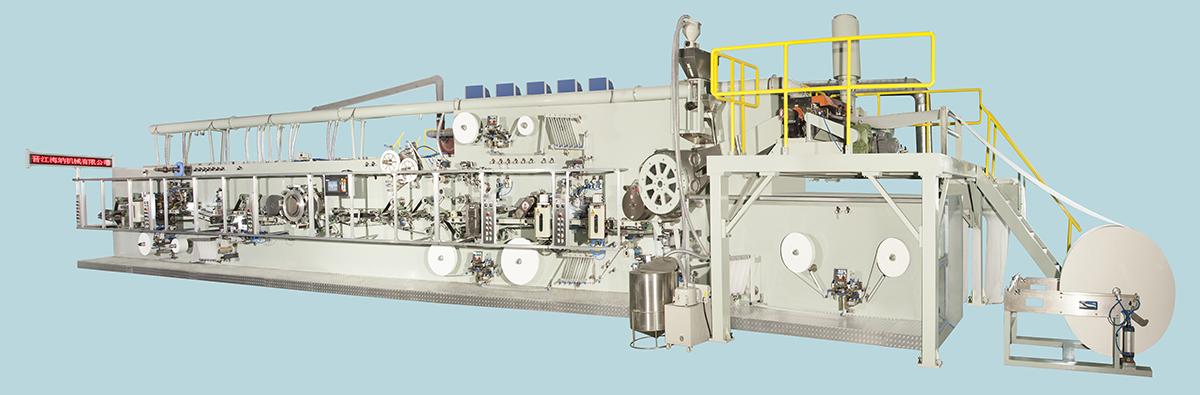

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-23

Introduction: from different angles, the faults of Best Sanitary Pads Manufacturing Machine design have the same classification methods. There are usually the following classification methods.

1) Deterioration: when the equipment is put into use, with the passage of time, under the influence of various factors, the parts will undergo irreversible change processes such as wear, pull-out, corrosion, creep and the change of metal material structure. These change processes will gradually reduce the function of sanitary pads machinery design with time, which is called deterioration fault.

2) Artificial: because the management system is not perfect, it is used in violation of the use regulations and maintenance regulations, such as overload use, overspeed use and use in violation of the operating procedures. The abnormalities caused by this are called artificial faults, also known as misuse.

1) Temporary: the loss of some local functions that occur in a very short time and cannot be used. There is no need to repair or replace parts after the occurrence, as long as the problem part is adjusted and its lost function can be restored.

2) Durability: the loss of equipment function can not be restored until the abnormal parts are replaced or repaired.

1) Sudden: due to the joint action of various adverse factors of the equipment itself and accidental external factors, this effect will occur rapidly when it exceeds the limit that the equipment can bear. The characteristic of this kind is that the time of its occurrence and sitting is related to the state change of the equipment and the time when the equipment has been used, which occurs suddenly without obvious warning. This can not rely on early tests and tests to predict the time of its occurrence, so it is also called unmonitored.

2) Progressive: caused by various aging processes. The characteristic of this kind is that its occurrence time is related to the working time of the equipment. The longer the equipment is used, the higher the probability of occurrence. This kind of delayed fault provides the possibility of monitoring. Therefore, it is often called monitorable.

1) Function: the equipment can not continue to complete its predetermined functions, such as the internal combustion engine can not be started due to abnormalities, the oil pump can supply oil, the reducer can not transmit movement, etc. This problem is often caused by damage or jamming of individual parts of the equipment.

2) Parameters: the specified parameters of the equipment exceed the allowable limit value. For example, the machining accuracy of the machine tool cannot meet the specified requirements; Reduction of transmission efficiency; The lifting capacity cannot reach the standard value, etc. the question of parameters does not hinder the continuous operation of the equipment, but according to the standards of the technical documents of the equipment, the equipment is in the state of disaster affected working capacity or significantly reduced working capacity.

1) Catastrophic: sanitary pads machinery serious consequences such as equipment damage or casualties caused by the safety protection device of the equipment, braking device of the transmission system and other key parts.

2) Generality: no damage or casualties and other non dangerous. However, such problems may still result in the reduction of mechanical performance, impact on use, interruption of production or about economic losses.

1) Actual: failure of the equipment.

2) Potential: there are possible abnormalities in the equipment itself. In the production process, strictly implementing the use and maintenance procedures of sanitary pads machinery equipment and taking effective diagnostic measures will prevent potential abnormal development from forming actual faults.

There are various failure modes of Best Sanitary Pads Manufacturing Machine, but each one needs to be understood by operators and managers. Only by doing well in maintenance and repair can the machine reach the best working state and reduce casualties and economic losses.