Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-07

The maintenance of sanitary napkins making machine generally includes daily maintenance, regular maintenance, regular inspection and accuracy inspection. The maintenance of lubrication and cooling system is also an important part of equipment maintenance. Routine maintenance of sanitary napkins making machine is a basic work, and regular inspection is a necessary work, which must be institutionalized and standardized.

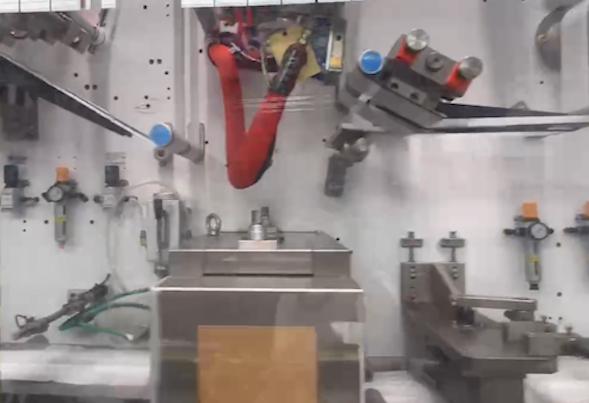

Machine to make sanitary pads are cared for by wiping, cleaning, lubrication, adjustment and other methods to maintain and protect the performance and technical status of the equipment, which is called equipment maintenance. There are four main requirements for the maintenance of sanitary napkins making machine:

(1) Cleaning

The inside and outside of the equipment shall be clean, and the sliding surfaces, lead screws, racks, gear boxes, oil holes, etc. shall be free of oil, and all parts shall be free of oil and gas leakage. The chips, sundries and dirt around the equipment shall be cleaned.

(2) Neat

Tools, accessories and workpieces (products) should be placed neatly, and pipelines and lines should be in order.

(3) Good lubrication

Refuel or change the oil on time, constantly, without dry friction, the oil pressure is normal, the oil mark is bright, the oil circuit is unblocked, the oil quality meets the requirements, and the oil gun, oil cup and felt are clean.

(4) Security

Observe the safety operation regulations, do not overload the equipment, the safety protection devices of the equipment are complete and reliable, and eliminate unsafe factors in time.

Sanitary napkins making machine periodic inspection is a planned preventive inspection. In addition to human senses, there should also be certain inspection tools and instruments, which should be carried out according to the periodic inspection card. Periodic inspection is also called periodic spot inspection. The accuracy of sanitary napkins making machine should also be checked to determine the actual accuracy of the equipment.

Equipment maintenance shall be carried out in accordance with maintenance procedures. The equipment maintenance procedures are the requirements and regulations for the daily maintenance of the equipment. Adhering to the equipment maintenance procedures can prolong the service life of the equipment and ensure a safe and comfortable working environment.

Its main contents should include:

(1) The equipment shall meet the operation contents, operation methods, tools and materials used, standards and precautions of tidiness, cleanness, firmness, lubrication, corrosion prevention, safety, etc.

(2) The parts, methods and standards of daily inspection, maintenance and regular inspection.

(3) Check and evaluate the contents and methods of equipment maintenance degree of operators.

(1) Specify the user. According to the fixed person and machine system, the operators of sanitary napkins making machine should choose those who have a strong sense of responsibility, high technical level and rich practical experience in woodworking, and keep them relatively stable for a long time as possible.

(2) Assign maintenance personnel. Enterprises with many sanitary napkins making machines can organize professional equipment maintenance or repair groups to be responsible for equipment inspection, precision adjustment, maintenance and repair according to their own conditions.

(3) Set operating procedures. The operating procedures shall be prepared one by one according to the type of equipment, displayed and strictly implemented.

(4) Order spare parts. According to the role of various equipment in enterprise production and the source of spare parts, determine the reserve quota and give priority to solving it.

For the regular maintenance of sanitary making machine, work quota and material consumption quota should be formulated and assessed according to the quota. The regular maintenance of equipment should be included in the assessment of staff, and the unity of knowledge and practice should be ensured.