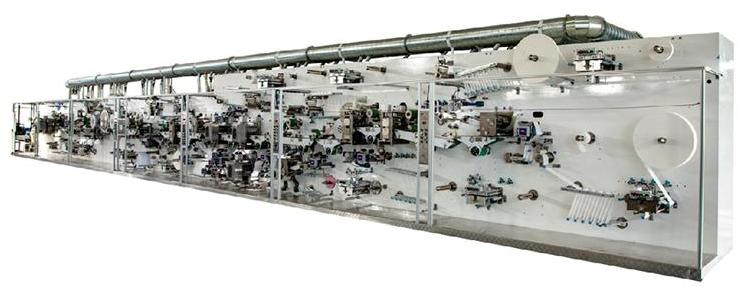

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-30

The method of removing fully automatic sanitary pad machine parts by using the static tension or not too large impact force generated by the interaction between general or special tools and parts. This method will not damage parts and is suitable for parts with high disassembly accuracy.

The pin puller pulls the conical pin: a) it is used to pull the conical pin with internal thread at the big end; b) Used to pull the tapered pin with spiral tail. When pulling, it generates impact force by the impact of the weight of the pin puller to pull the conical pin out of the mating part.

The disassembly of belt pulley, sprocket, gear and rolling bearing at the shaft end of sanitary pad machinery can be pulled out by various screw pullers.

Because the bushing is mainly made of soft copper alloy, cast iron or bearing alloy, it is easy to deform or damage if it is pulled out improperly. Therefore, it is not necessary to remove as much as possible. It must be removed with a special tool before it can be pulled out.

The drawing and disassembly method of fully automatic sanitary pad machine is relatively simple, but again, it is simple. Experienced personnel must be on the side to assist, rather than allowing novices to operate at will. In this way, it is easy to damage the machine and yourself.