Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-13

It is very necessary to increase the development and application of energy-saving technology of machine to make sanitary pads, and it has become the key task of daily-use production machinery industry in the current period. Improve the energy-saving technology of sanitary making machine, including single product energy-saving and system energy-saving technology.

Realizing efficient product design from the design stage is an important work that affects the mechanical performance, quality and energy-saving level. Whether the sanitary making machine can meet the user's use and energy-saving requirements depends on the product design to a great extent.

To improve the design level of machine to make sanitary pads, the following principles should be followed: the user should reasonably determine the performance parameters and necessary working conditions of internal components; The design department shall reasonably determine the types and parameters of internal components and reasonably meet the on-site use conditions; Fully consider the maximum efficiency and scope of internal components and actual use efficiency indicators. Carry out technical and economic comparison, and select the scheme with advanced technology and reasonable economy.

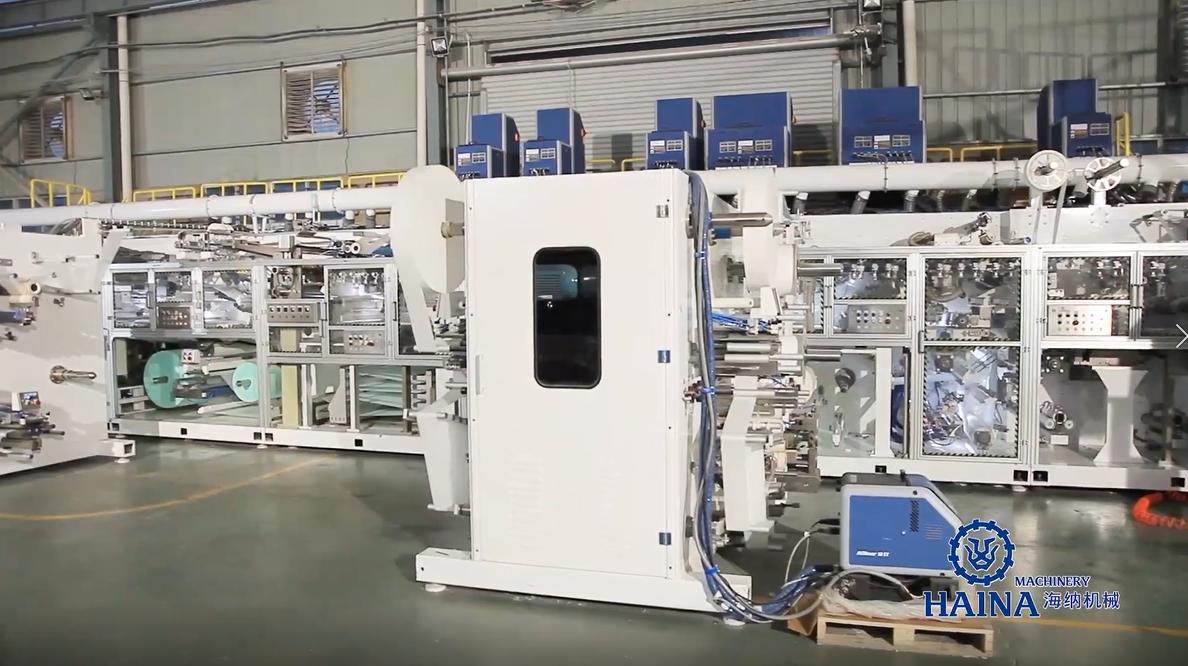

Sanitary making machine is composed of various parts. Each part plays an important role in the overall performance of the product. The quality of parts is the key to ensure the performance, service life and energy-saving effect of sanitary making machine. Therefore, improving the processing quality is the key to ensure the performance and efficiency of pumps, fans and compressors.

There are two indicators to measure the quality of machine to make sanitary pads, namely, machining accuracy and assembly. Design and processing technology promote each other. Advanced design should be guaranteed by advanced processing technology and equipment. The development of technology can promote the development of product design and improve the level of product design.

Significant energy saving effect can be obtained by adjusting the running speed of internal components of machine to make sanitary pads. In the production of daily-use products, these machines are generally driven by AC motors, and the power is more than hundreds of kilowatts, some as high as thousands or even tens of thousands of kilowatts, which consumes a lot of electric energy. However, most of them do not work under rated conditions all year round, and often only have 50% - 70% or even lower output. At present, most of these machines still use constant speed AC drive, which is adjusted by baffle, valve or air discharge and return flow, resulting in a large loss of electric energy.

Using frequency conversion speed regulation to replace the regulation mode with serious energy waste can reduce vibration, eliminate the current impact of large motor starting, avoid mechanical oscillation, reduce the equipment failure rate and reduce the maintenance workload of semi-automatic baby diaper machine.

In the field of daily-use production, machine to make sanitary pads is an essential equipment in production and construction. It has been widely used in national economic departments. Its development speed is much higher than that of national economy. Improving the efficiency of equipment is the primary task of the industry at present.