Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-02-08

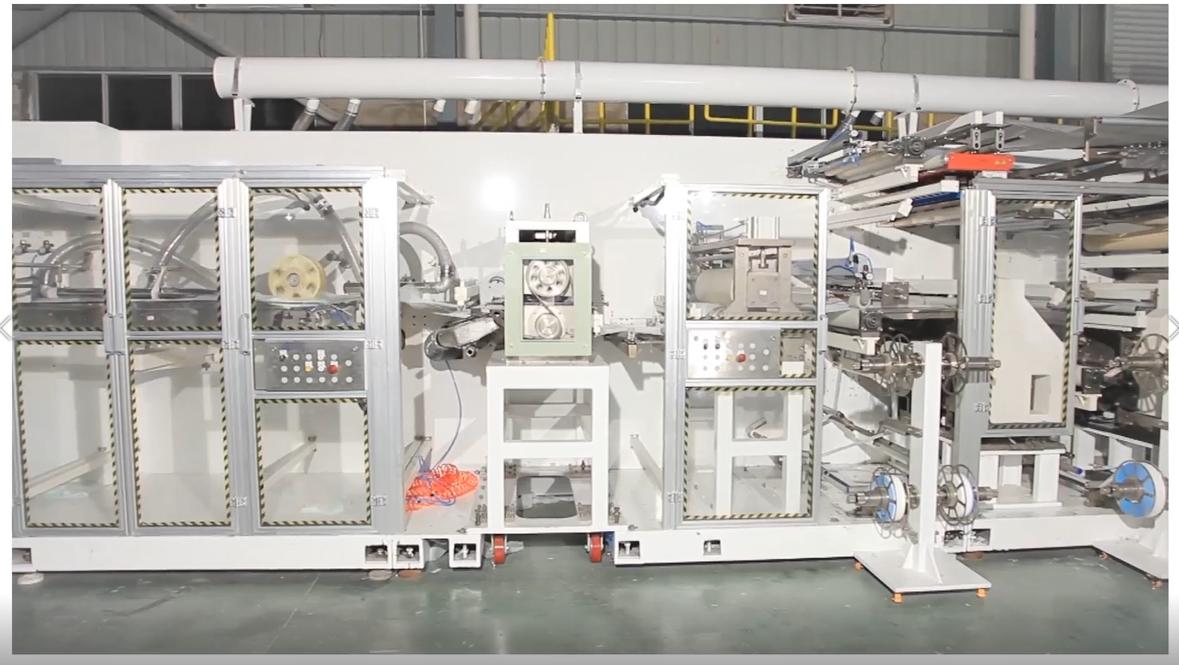

The design process of fully automatic diaper machine is very complex, mainly because it involves many aspects. Market research, technical prediction and ergonomics are indispensable. However, due to many kinds and large performance differences, the design process is not fixed. However, for designers, changes are inseparable from their religion. There are still certain rules to follow in the design of fully automatic diaper equipment.

When designers accept a new design task, they usually need to understand the designed equipment. At this time, the functional scope and indicators of fully automatic diaper production line should be determined according to the use requirements and working conditions, and the problems to be solved in the design process should be clarified.

After understanding the problems to be solved in the design, put forward a variety of schemes for the functional possibility of the equipment, including prime mover, transmission and working mechanism. After that, according to the use requirements of fully automatic diaper equipment and the current technical level and economic basis of the enterprise, all external conditions should be considered and each scheme should be comprehensively analyzed. Through analysis, determine the prime mover, select the transmission mechanism, determine the working principle and working parameters of the working mechanism, and complete the drawing of the principle working diagram.

The technical design of fully automatic diaper equipment is the core. During the technical design, it is necessary to ensure the data accuracy of design calculation and check calculation. At the same time, ensure the integrity and correctness of the general assembly drawing, component assembly drawing and part working drawing of the product.

The main contents of technical design include:

(1) Kinematic design: according to the design method and the working parameters of the working mechanism, the dynamic parameters of the prime mover are obtained.

(2) Dynamic calculation: calculate the load acting on the part according to the results of kinematic design.

(3) Part design: according to the load and design principles of parts, the basic dimensions of parts are obtained through calculation and test.

(4) General Assembly sketch: make the General Assembly sketch according to the dimension and mechanism structure relationship of the parts, and complete the part structure and dimension design on the basis of comprehensively considering the assembly, adjustment and lubrication of the parts.

In the process of fully automatic diaper machine design, every link is essential. If there is a problem in one link, it will directly affect the design result. This will allow the designer to return to the design before modification until the problem is solved. Mechanical design is an iterative process, so designers need to complete this process accurately and patiently.