Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-07-18

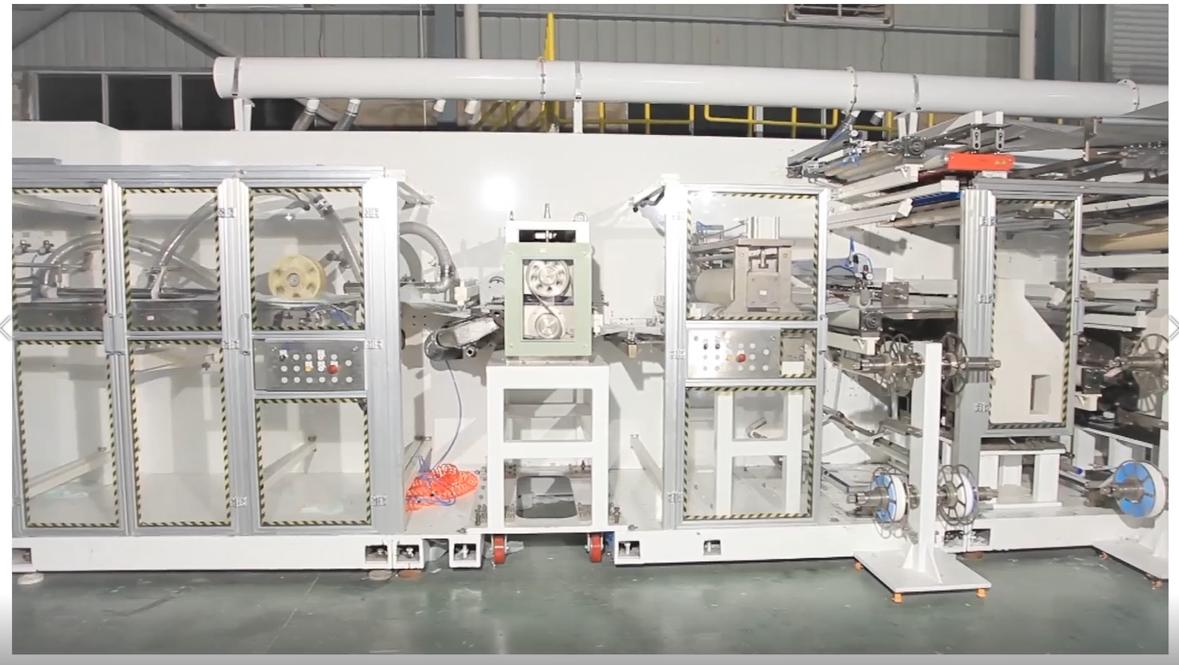

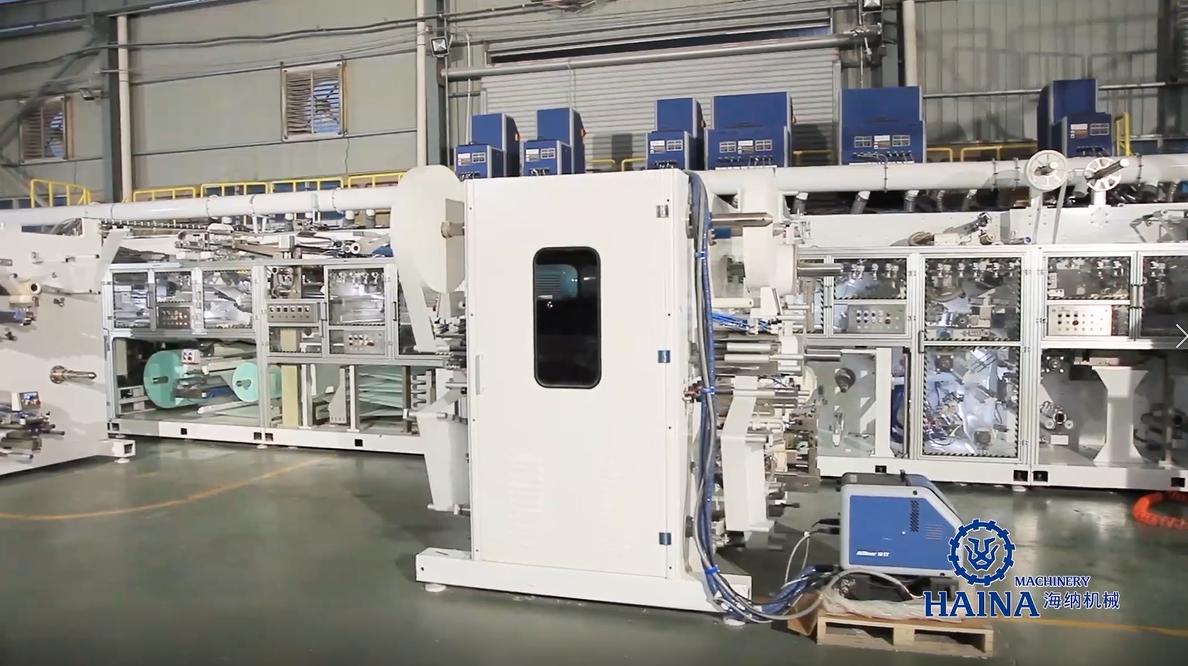

The current era is in the information age, and human labor has been gradually replaced by mechanized equipment and high-tech products. Labor operations in large factories as well as high-end industries are performed by high-end machinery. In the diaper industry, pull up baby diaper machine has been widely used in many fields. Therefore, the safety management and maintenance of pull up baby diaper equipment has become an important issue facing the country and enterprises.

In the process of machinery manufacturing equipment, the basic principle of safety management is that safety dominates, and everything is less important than safety. The maintenance principle is to maintain at any time, clean the equipment for the first time, ensure that new tools are prevented from damage, always maintain the best working condition, prolong service life, improve production efficiency. In short, it can be summed up in a slogan: "Safety management is always in my heart. Maintained at any time, often used and always new".

The basic task of machinery safety management is that in the production process, in order to expand the scope of safe use of machinery, the primary task of the enterprise is to establish a complete management system, and then formulate reasonable and orderly use procedures and regulations on this basis. The basic tasks of mechanical maintenance can be carried out at any time, that is, after each work, clean up tools in time, check useless equipment at any time, and repair in time once problems are found to avoid unnecessary safety risks and maximize production efficiency.

The concept of management and maintenance is weak: the basic problem in management is that the enterprise itself does not have a correct attitude towards management and maintenance, and the importance of it is not obvious enough and the awareness is relatively weak. The main reason for this is that in order to survive and occupy a certain market position in today's rapidly developing market economy, the profit efficiency has been greatly improved. However, some problems have arisen in the process. For example, in order to quickly occupy a place in the market and reduce costs, enterprises often ignore the ontology capabilities and the safety performance of machinery. It is precisely because they do not pay attention to the safety performance of pull up baby diaper equipment, so Some equipment problems have not been discovered and solved in time, resulting in serious aging, and some damaged equipment has not been replaced in time. If things go on like this, it will affect the normal production and operation, and even endanger the personal safety of workers, which is very easy to cause safety. ACCIDENT.

People's unsafe behavior: Another main reason for the problem is people's unsafe behavior, and there are many factors affecting people's unsafe behavior, which involve a wide range and are mainly manifested in the following aspects.

(1) Unprofessional technology, unable to calmly and properly handle unexpected situations and lack of basic knowledge and lack of understanding of some equipment.

(2) Not having good work habits.

(3) The cultural quality of the staff is low, and the safety awareness is weak.

When there is a problem during the operation of pull up baby diaper machine , the technicians will handle and adjust it according to the relevant safety system and the use and maintenance specifications formulated by the enterprise. So as to ensure the smooth progress of the production process. However, in the actual operation process, the basic requirement of maintenance work is to be "scientific, efficient and safe." The implication is that, according to the standardized operation method, the machine can be adjusted to the best state in a short time under the premise of ensuring its own safety, so as to reduce costs. , so that the efficiency reaches a high standard.