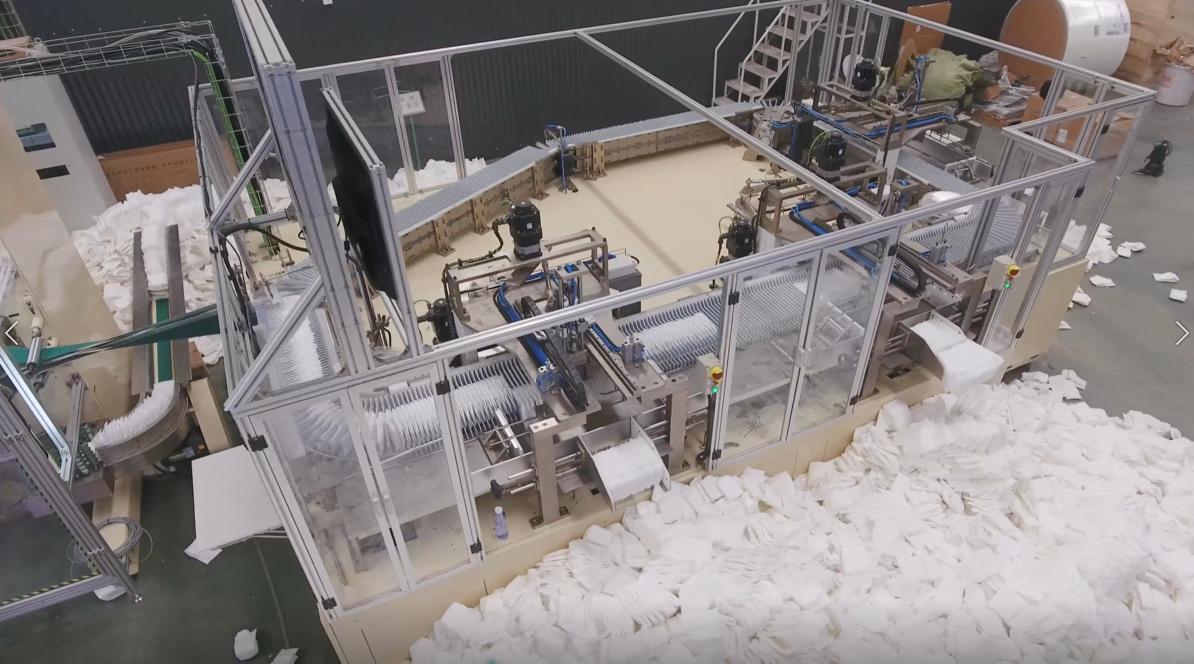

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-07-18

With the continuous progress of science and technology and the rapid development of modern production, the role of machine as an important factor determining the output, quality and cost of product production is becoming more and more obvious. In the process of use, the pull up baby diaper machine will inevitably produce varying degrees of wear, fatigue, deformation or damage. With the passage of time, the technical state of pull-up baby diaper equipment will gradually deteriorate and the use performance will also decline. As an important part of management, equipment maintenance is an important guarantee to prolong its service life, ensure the normal operation of production and prevent accidents. With the progress of production technology, enterprises have more and more types of equipment and stronger technicality. Its different use environments and failure rate curves are different. How to choose maintenance strategy for pull-up baby diaper equipment?

Generally speaking, the larger the enterprise, the more equipment. The number of large and medium-sized enterprises is very large. Different equipment plays different roles in the production and operation of enterprises, and the maintenance methods are also different. When formulating the machine maintenance strategy, the importance of equipment should be classified first. There are many classification methods, among which ABC classification is a common and better method.

In a unit, the number of class a equipment is small and plays a great role, accounting for about 10% of the total. The configuration process is complex and is the key equipment in the production process of the enterprise. Once these equipment fails, it will cause significant economic losses and have a significant impact on the enterprise. Therefore, these equipment need to have high reliability in the operation process. This should be the focus of maintenance work. For these key machines, appropriate repair methods should be selected from the economy of maintenance.

It is better to adopt the condition based maintenance mode for this kind of equipment, and change the planned maintenance to targeted maintenance. The implementation of condition based maintenance can greatly reduce the maintenance workload and maintenance cost, and achieve the effect of less input and more output. If there is no corresponding diagnostic equipment, or the cost of condition based maintenance is too high, the results of technical and economic analysis are inappropriate and the enterprise cannot afford it, the standard maintenance method or regular maintenance method should be adopted.

When repairing class B and class C equipment, appropriate repair methods shall be selected according to the equipment fault information. For these equipment, fault information is the basis for determining the maintenance mode. Through the analysis of fault information, the type of fault can be judged and the maintenance mode can be selected. Fault information mainly includes statistics on the number of equipment faults (shutdown frequency) and fault consequences (shutdown time, economic loss, etc.).

Collect statistical data on shutdown frequency (Times) and downtime of one year (or half a year, quarter and month). Plot downtime and frequency. Each unit has a large number of equipment. It is only necessary to list the equipment with the longest downtime and the largest number of downtime, accounting for more than 80% of the total. For equipment with long downtime and high frequency, planned maintenance shall be adopted to completely eliminate faults. For the equipment with low shutdown frequency but requiring a long shutdown time, the process and causes of fault shutdown shall be analyzed, and condition monitoring and condition repair shall be carried out. For equipment with high shutdown frequency and short shutdown time, the maintenance strategy is to improve the skill level of operators, which is generally completed by them. For the equipment with short downtime and low frequency, the mode of no damage and no repair is adopted.

The quality of the machine is the basis of safe production. Their operation quality is very high, and the annual maintenance cost is also very high. Compared with the general mechanical maintenance strategy, it has both its commonness and particularity. The principles and viewpoints proposed in this paper need to be further deepened and refined according to the characteristics of the industry, so as to formulate a set of pull-up baby diaper mechanical maintenance strategy.