1. Prepare the Machine. 2. Set Up the Machine Parameters. 3. Load the Raw Materials. 4. Start the Machine. 5. Regular Maintenance Checks. 6. Quality Control Mea...

Introduction. 1. Site Selection. 2. Machine Placement. 3. Machine Assembly. 4. Connection to Utilities. 5. Testing and Calibration. 6. Safety Measures. 7. Opera...

1. Increased Production Efficiency. 2. Consistent Product Quality. 3. Cost-effective Production. 4. Flexibility in Design and Features. 5. Quick Changeover and ...

Today, with the development of the hygiene industry, it is necessary to strengthen the daily maintenance and management of Baby diaper making machine. Lack of a...

At present, we use a lot of baby diaper making machine in the market, but different manufacturers of equipment, each equipment has its own use method, if not us...

1. estrutura do produto: Tecido superior e inferior (ou airlaid), núcleo de algodão (misturado com SAP), não tecido hidrofílico da folha superior, não tecido ADL, manguito de vazam...

1. Sistema de programação da máquina de fraldas para bebês tipo T-Shape Ear Servoacionado, interface homem-máquina com tela de toque HMI inteligente 2. Sistema de tensão Controle...

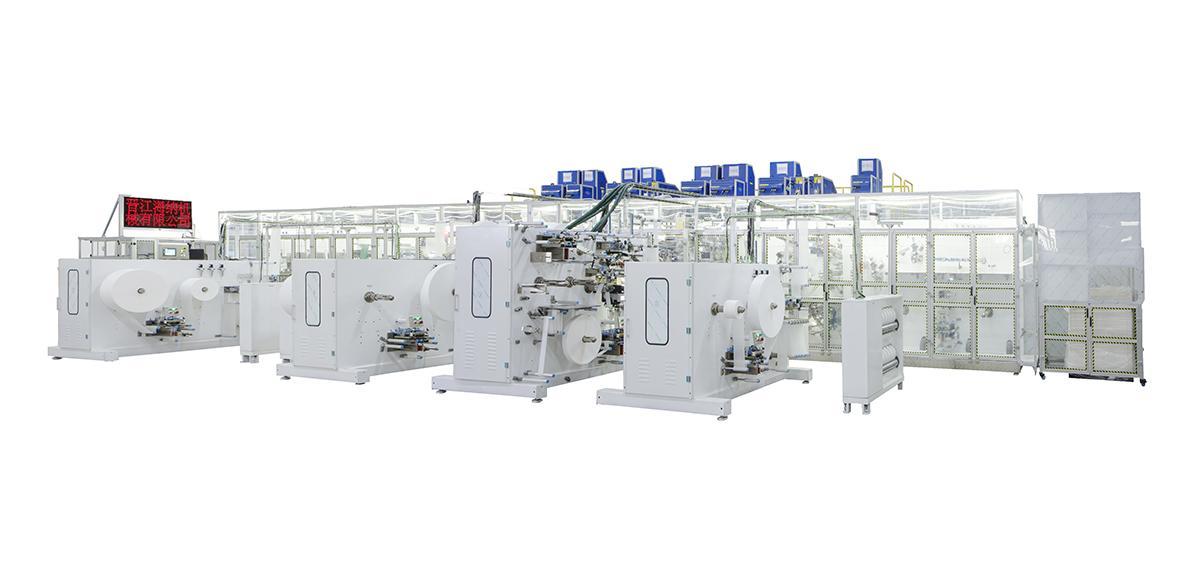

The Pampers making machine is a top-of-the-line piece of equipment designed to efficiently manufacture high-quality diapers. Its advanced features include automatic feeding, cutting, an...

This is Sanitary Pad Manufacturing Machine in Croatia. This machine can produce 350mm/410mm two sizes, design speed is 1000ppm, stable working speed is 600ppm for 350mm while 500ppm for...

This is Pull up Baby Diaper Machine in Saudi Arabic. This machine can produce 4 sizes, M/L/XL/XXL for the market and now this pull up baby diaper is more and more popular in Saudi Arab...