Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-10-16

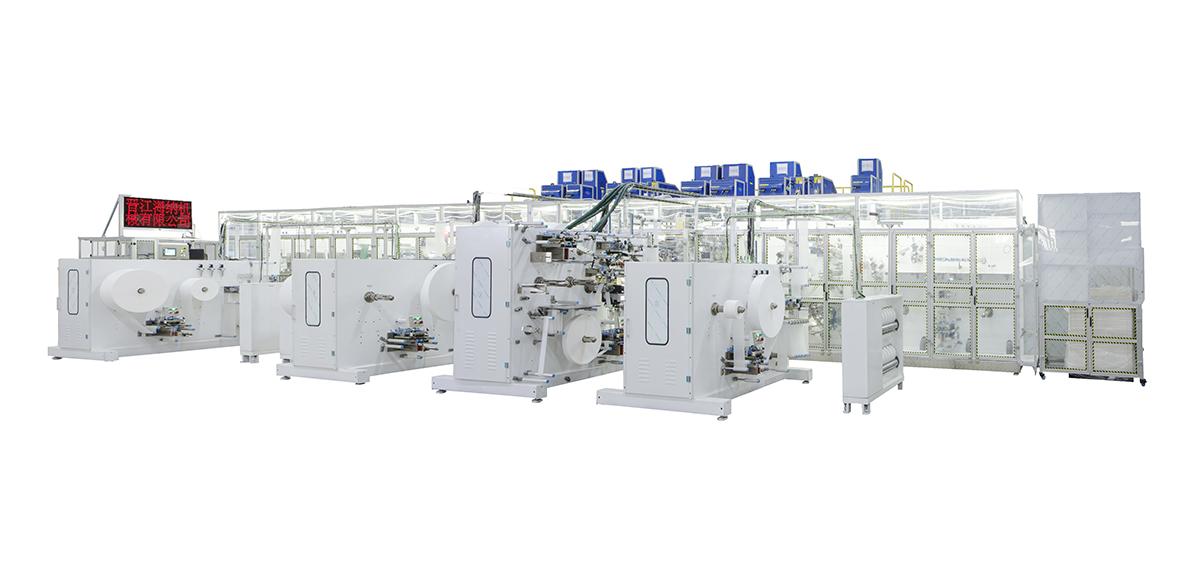

Efficient usage of a disposable nappy machine

The disposable nappy industry has experienced significant growth in recent years due to its convenience and practicality. With the increasing demand for disposable nappies, manufacturers are continually looking for ways to improve the efficiency of their production processes. One crucial aspect of this is the efficient usage of a disposable nappy machine. This article explores the importance of utilizing these machines effectively and provides insights into three key strategies for maximizing productivity and reducing waste.

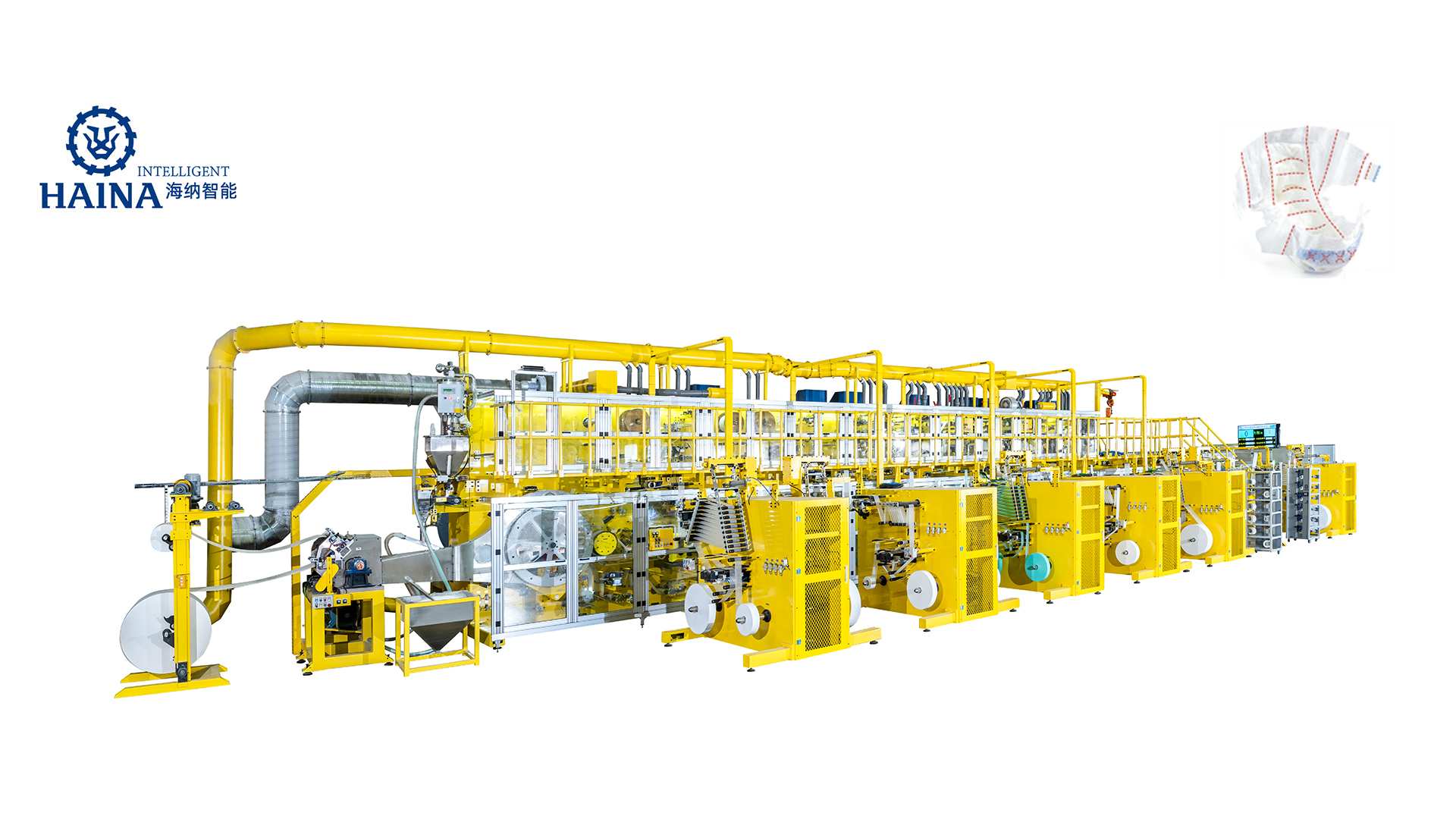

To ensure efficient usage of a disposable nappy machine, it is essential to optimize the machine settings. Manufacturers should regularly review and adjust settings such as temperature, speed, and pressure to achieve optimal results. By fine-tuning these parameters, it is possible to minimize the occurrence of defects and improve the overall quality of the nappies. Additionally, monitoring and maintaining the machine's mechanical components, such as blades and rollers, can prevent unnecessary downtime and ensure consistent performance.

Efficient material handling is another critical factor in maximizing the productivity of a disposable nappy machine. Raw materials, such as absorbent cores, elastic bands, and outer layers, should be organized and easily accessible for smooth and uninterrupted production. Implementing automated systems for material feeding and removal can eliminate bottlenecks and reduce the reliance on manual labor. Furthermore, adopting a just-in-time inventory management approach can help minimize waste and optimize the utilization of materials.

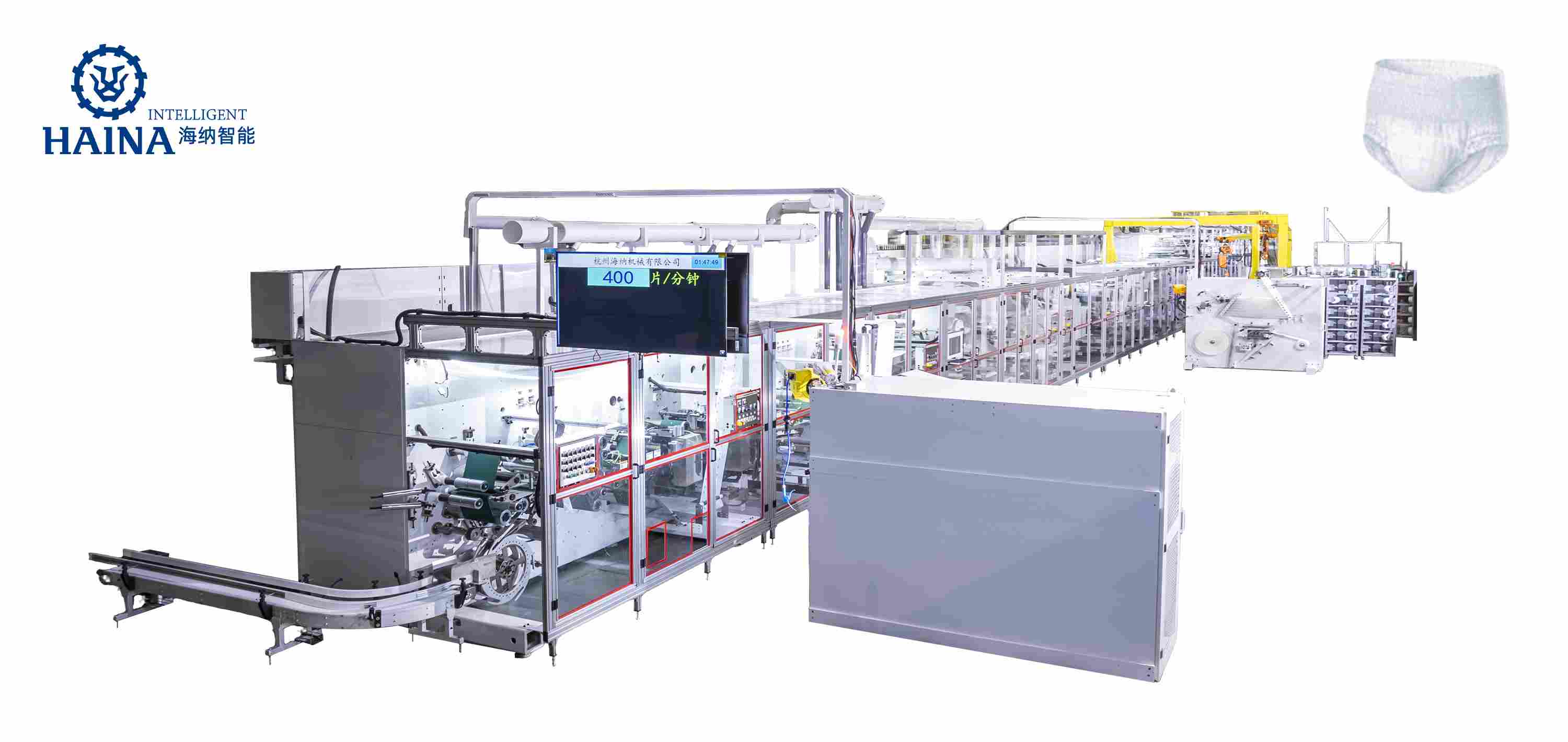

Implementing robust quality control measures is vital to ensure the consistent production of high-quality disposable nappies. Regularly inspecting the final products for defects and inconsistencies can identify potential issues early on. Utilizing advanced technologies such as sensors and machine vision systems can automate the inspection process and enhance accuracy. Additionally, establishing a feedback loop with operators and integrating their knowledge and expertise can contribute to continuous improvement in product quality and machine performance.

In conclusion, efficient usage of a disposable nappy machine is paramount for manufacturers seeking to optimize productivity and reduce waste. By optimizing machine settings, streamlining material handling, and implementing quality control measures, manufacturers can enhance the overall efficiency of their production processes. As the disposable nappy industry continues to grow, embracing these strategies will ensure manufacturers stay competitive while meeting the increasing demand for these essential hygiene products.